Learning Factory for training and teaching Advanced Manufacturing

The most comprehensive blog post about physical learning factories used for education, training and upskilling of current or future machine operators, technicians, engineers, and production managers.

We will cover various parameters as per below.

- What is a Learning Factory?

- Core components of a Learning Factory

- Industry Collaboration in a Learning Factory

- Skills Development in a Learning Factory

- Innovation & Research in a Learning Factory

- Benefits and Impacts of a Learning Factory

- Challenges and suitable Solutions

- Future of Learning Factories

- How to Setup a Learning Factory

- Learning Factory Resources

After reading this extensive article you will know what a Learning Factory can do for the learners in your organization, as well as the wider community.

You will also know about trends, examples and how to get going on setting up your own Learning Factory.

Let us jump right in!

Introduction

In today’s fast-changing industrial landscape, a highly skilled workforce is essential. As manufacturing technologies advance, traditional education often falls short of meeting modern workplace demands. Learning factories address this gap by offering hands-on training in manufacturing and production processes, blending theoretical knowledge with practical skills.

Initially simple workshops, learning factories have evolved into sophisticated environments mirroring real-world manufacturing, equipped with advanced machinery, digital technologies, and cutting-edge production processes. They serve as educational hubs, innovation centers, and bridges between academia and industry, ensuring programs align with industry standards while advancing manufacturing practices.

This blog explores learning factories' core components, educational approaches, and their vital role in fostering industry collaboration, innovation, and workforce development.

1. What is a Learning Factory?

The best definition of a learning factory which we have found comes from the book Learning Factories, Concepts, Guidelines, Best-practice examples.

“A Learning Factory in a narrow sense is a learning environment specified by

- processes that are authentic, include multiple stations, and comprise technical as well as organizational aspects,

- a setting that is changeable and resembles a real value chain,

- a physical product being manufactured, and

- a didactical concept that comprises formal, informal and non-formal learning, enabled by own actions of the trainees in an on-site learning approach.

Depending on the purpose of a learning factory, learning takes place through teaching, training and/or research. Consequently, learning outcomes may be competency development and/or innovation. An operating model ensuring the sustained operation of the Learning Factory is desirable.

In a broader sense, learning environments meeting the definition above but with

- a setting that resembles a virtual instead of physical value chain, or

- a service product instead of a physical product, or

- a dedicated concept based on remote learning instead of on-site learning

can also be considered as learning factories.”

2. Core Components of a Learning Factory

Learning factories provide immersive education that mirrors real-world manufacturing environments. By integrating advanced tools, technologies, and teaching methods, they equip learners with essential modern manufacturing skills. Key components include:

Realistic Manufacturing Environment

Learning factories replicate actual production settings with CNC machines, robotic arms, and assembly lines. Students work in simulated workflows, gaining direct experience with industry-standard tools.

Practical Training Programs

Programs range from workshops to degree courses in fields like mechanical and industrial engineering, emphasizing hands-on training in machining, quality control, production planning, and maintenance.

Hands-On Learning

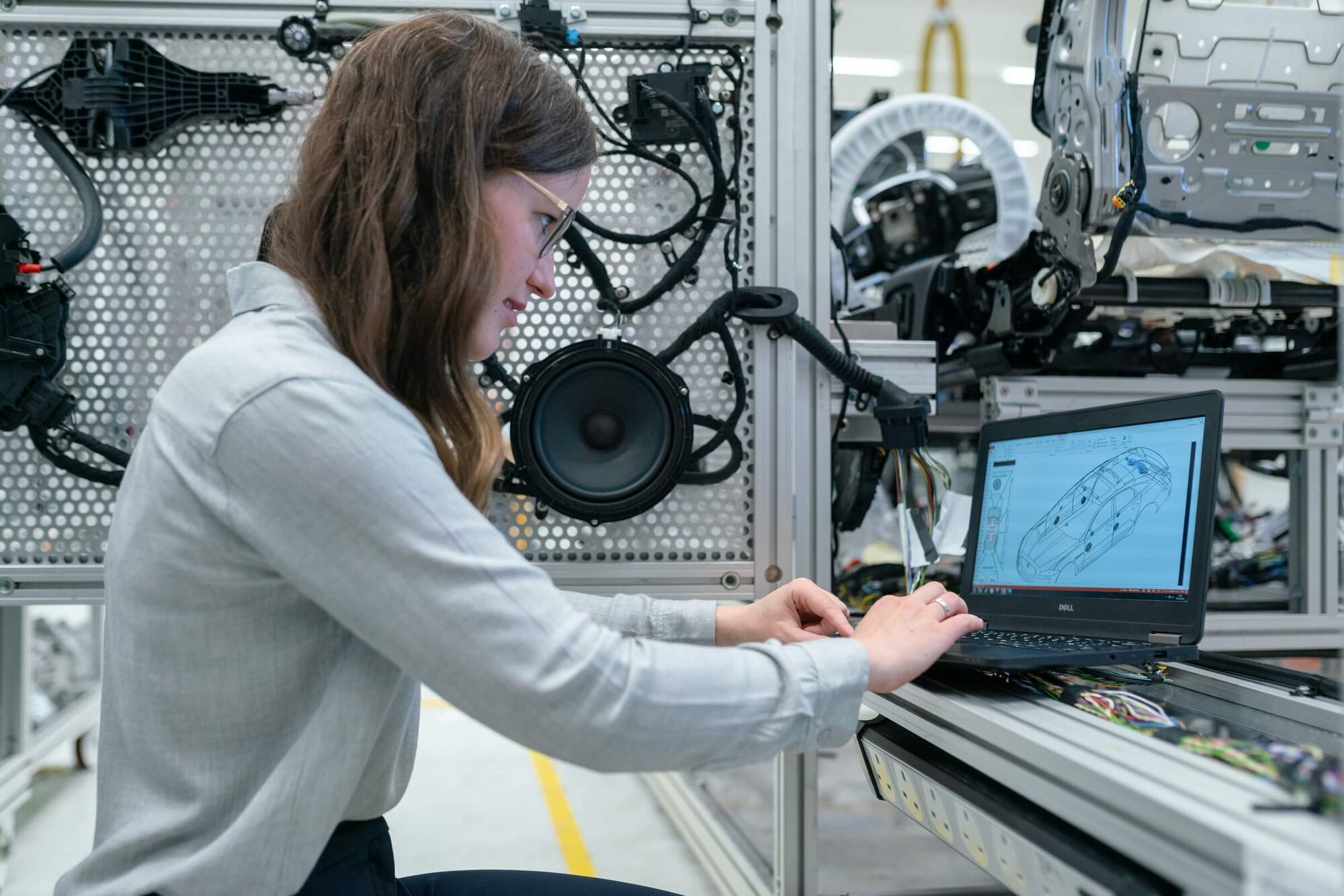

The integration of theory and practice ensures students actively apply concepts by working with equipment, participating in production simulations, and tackling real-world challenges.

Interdisciplinary Approach

Courses blend engineering, technology, business, and management, preparing students for roles that require knowledge of logistics, supply chains, and cost optimization.

Digital Tools and Simulation

Simulation software and tools like CAD, CAM, and digital twins allow learners to model processes, optimize workflows, and enhance problem-solving skills without physical trials.

Real-World Projects

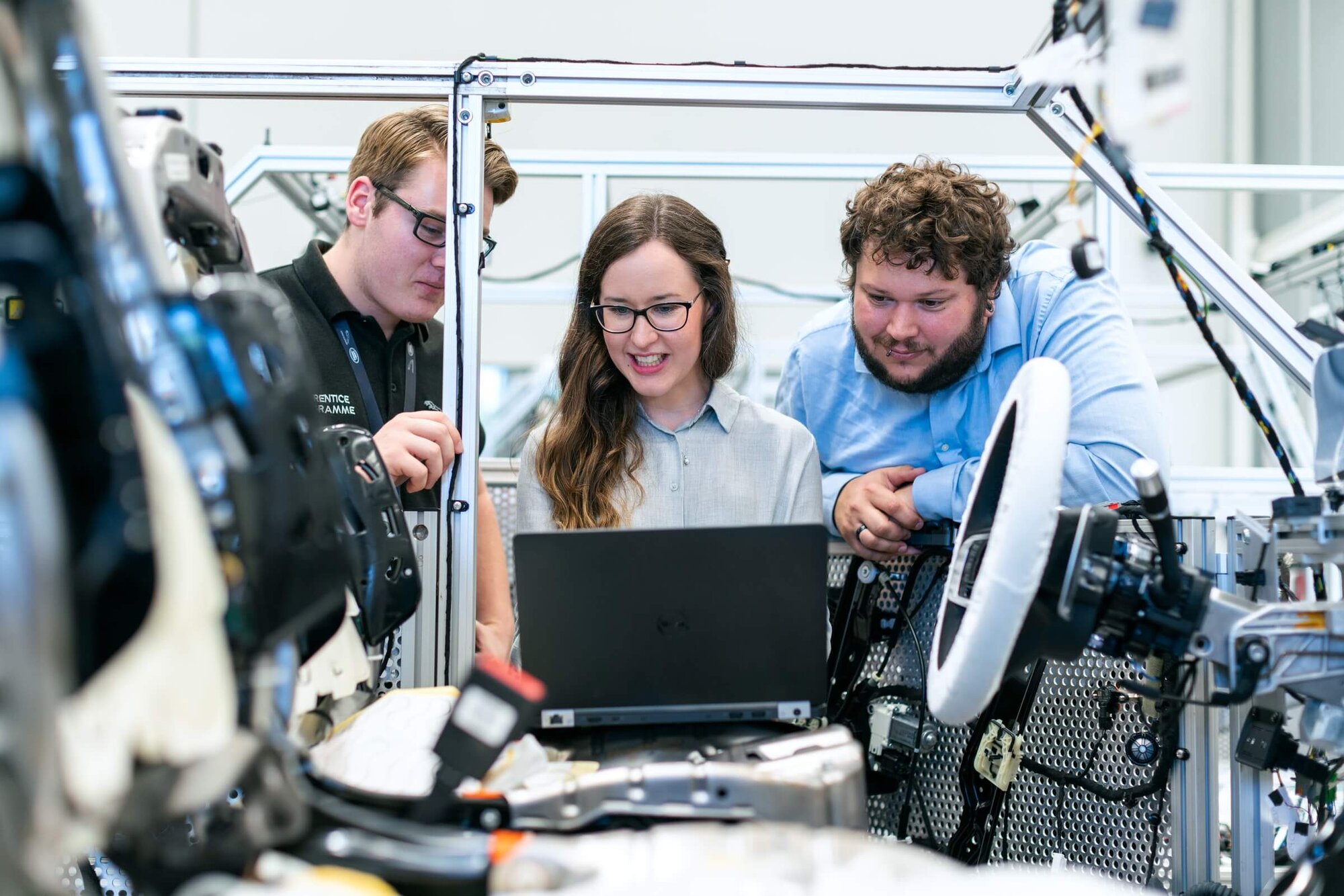

Collaborating with industry partners, students solve actual manufacturing problems, gaining practical experience in project management and teamwork.

Continuous Feedback

Frequent feedback from instructors and industry mentors fosters skill refinement and confidence while promoting lifelong learning and adaptability to industry trends.

By combining practical skills with cutting-edge technology and interdisciplinary education, learning factories prepare students for success in modern manufacturing.

3. Industry Collaboration in a Learning Factory

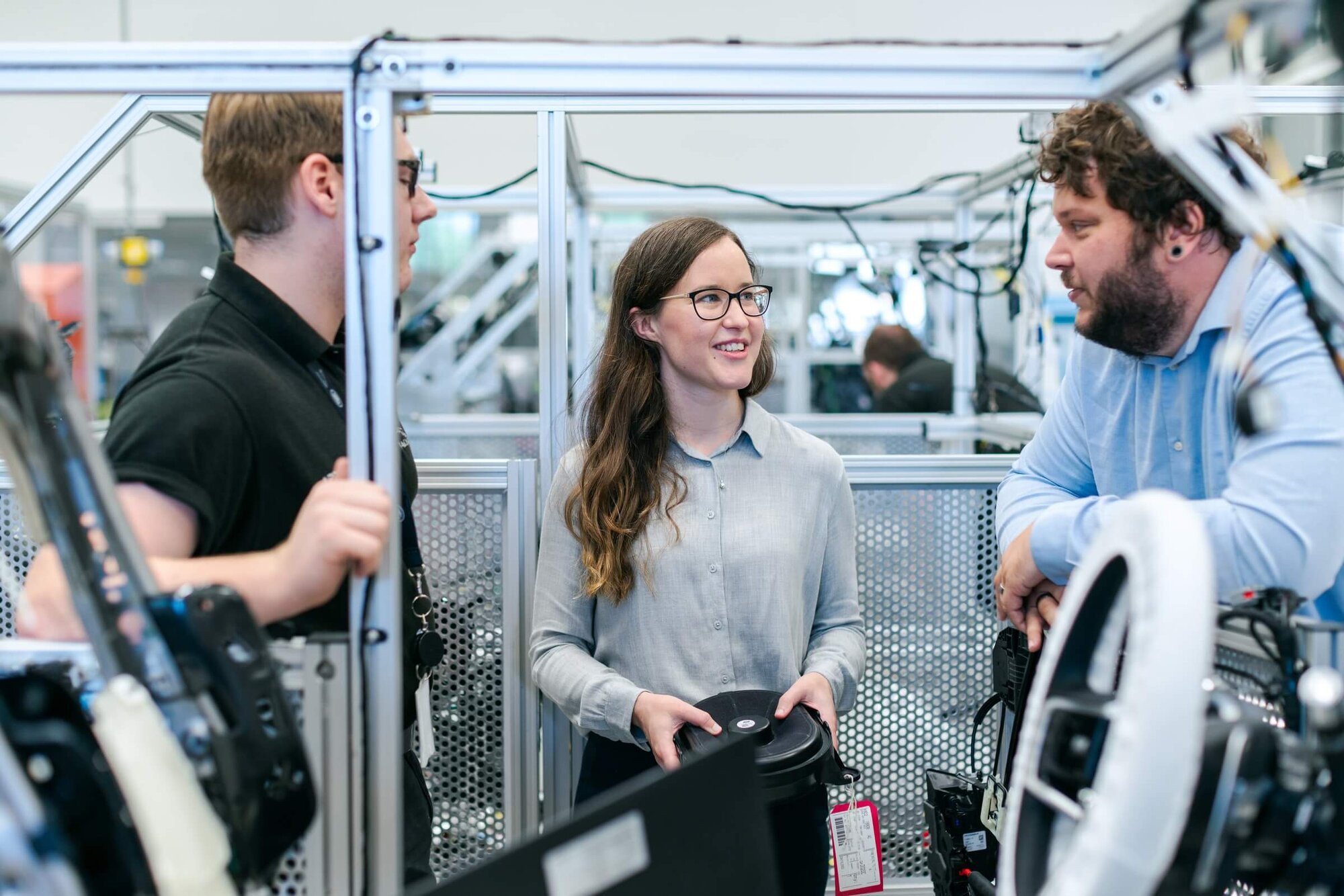

Industry collaboration sets learning factories apart by aligning education with market needs through partnerships, internships, research, and advisory initiatives.

Partnerships with Companies

Learning factories partner with manufacturing firms to stay current with industry trends. Companies contribute by:

- Donating advanced equipment and technology.

- Co-developing curricula to address industry demands.

- Hosting guest lectures and workshops led by industry experts.

Internships and Job Placement

Internships provide students with hands-on experience, professional skills, and job opportunities. Many learning factories also offer career services, such as resume building, interview prep, and job placement assistance.

Joint Research and Development

Collaboration with industry drives innovation through shared R&D projects, improving manufacturing practices, fostering sustainability, and enabling students to gain practical research experience.

Industry Advisory Boards

Advisory boards guide learning factories by:

- Reviewing and updating curricula to match industry trends.

- Evaluating program effectiveness.

- Shaping strategies to address future industry needs.

Real-World Problem Solving

Learning factories solve real industry challenges through consultancy projects, including process optimization, quality improvement, and sustainability initiatives, offering students practical experience and delivering value to companies.

By bridging academia and industry, learning factories create a dynamic ecosystem that enriches student education, fosters innovation, and supports manufacturing advancements.

4. Skills Development in a Learning Factory

Learning factories aim to equip students with technical and soft skills essential for modern manufacturing careers, blending hands-on training, interdisciplinary learning, and real-world applications.

Technical Skills

Students gain expertise in key manufacturing areas, including:

- Machining and Fabrication: Operating CNC machines, lathes, and mills to produce precision components.

- Robotics and Automation: Programming robotic systems and automated technologies like AGVs.

- Quality Control: Applying methods such as statistical process control (SPC) and non-destructive testing (NDT).

- Production Planning: Optimizing workflows with supply chain management and scheduling techniques.

- Maintenance and Troubleshooting: Diagnosing and repairing equipment to minimize downtime.

- CAD/CAM: Using digital tools for designing products and manufacturing processes.

Soft Skills

Critical interpersonal and cognitive abilities are developed through practical experiences, including:

- Teamwork: Collaborating effectively in group projects.

- Problem-Solving: Tackling real-world manufacturing challenges.

- Communication: Practicing clear and precise technical reporting and presentations.

- Leadership: Training in project and team management.

- Adaptability: Fostering a mindset of lifelong learning and responsiveness to industry changes.

- Sustainability: Emphasizing ethical practices and eco-friendly manufacturing.

Real-World Application

Students apply their skills through internships, industry projects, and simulation tools, gaining practical experience and insights into professional practices.

Continuous Feedback

Regular assessments from instructors and industry mentors help students refine their abilities, ensuring continuous improvement.

By integrating technical proficiency with essential soft skills, learning factories prepare students for success in a dynamic manufacturing environment.

5. Innovation and Research in a Learning Factory

Learning factories are dynamic hubs where students, educators, and industry professionals collaborate to advance manufacturing technologies. They foster innovation, conduct cutting-edge research, and bridge the gap between academia and industry.

Innovation Hub

Learning factories provide a realistic environment to develop and test new technologies and processes:

- Prototyping and Testing: Facilities enable the creation and refinement of prototypes and processes.

- Technology Integration: Students and researchers explore advanced robotics, IoT, and AI in manufacturing workflows.

Cutting-Edge Research

Research projects in learning factories address critical manufacturing challenges, such as:

- Advanced Techniques: Developing methods in additive manufacturing, precision machining, and nanotechnology.

- Smart Manufacturing: Exploring data-driven, automated, and interconnected production processes.

- Sustainability: Innovating energy-efficient methods, waste reduction, and eco-friendly materials.

Collaboration with Academia and Industry

Partnerships ensure practical, relevant research:

- Academic Collaboration: Universities and learning factories share expertise, enriching research and curricula.

- Industry Engagement: Companies provide funding, insights, and challenges, leading to practical solutions and mutual benefits.

Student Involvement

Students gain hands-on experience and contribute to meaningful advancements:

- Research Assistantships: Practical exposure to experiments, data analysis, and technology development.

- Capstone Projects: Tackling real-world challenges under expert guidance.

- Knowledge Dissemination: Opportunities to co-author papers and present findings, enhancing academic and professional growth.

Benefits to Academia and Industry

- Academia: New knowledge, enhanced curricula, and research excellence.

- Industry: Access to innovations, optimized processes, and a pipeline of skilled graduates.

Conclusion

Learning factories drive manufacturing innovation through research, collaboration, and student involvement. This synergy advances industry practices, enriches education, and ensures competitiveness in a rapidly evolving global market.

6. Benefits and Impact of a Learning Factory

Learning factories bridge the gap between theory and practice, benefiting students, industry, academia, and the broader community by driving innovation, fostering collaboration, and advancing manufacturing education.

For Students

- Employability: Graduates are highly sought after due to hands-on experience and practical skills.

- Comprehensive Skills: A blend of technical expertise and soft skills like teamwork and problem-solving.

- Real-World Exposure: Internships and industry projects prepare students for professional environments.

- Innovation Mindset: Working on cutting-edge projects fosters creativity and entrepreneurial thinking.

For Industry

- Skilled Talent: Access to job-ready graduates reduces onboarding costs.

- Collaborative R&D: Joint projects with learning factories address industry challenges and drive innovation.

- Access to Technology: Use of advanced equipment for prototyping and testing.

- Cost Efficiency: Partnerships reduce R&D expenses through shared expertise.

For Academia

- Relevant Curricula: Industry collaboration ensures programs meet job market demands.

- Research Opportunities: Real-world problems enrich academic research and innovation.

- Enhanced Reputation: Recognition for cutting-edge programs attracts top talent and resources.

- Funding Support: Industry partnerships bring financial backing and equipment.

Broader Impact

- Advancing Manufacturing: New technologies and processes improve efficiency and quality while reducing environmental impact.

- Economic Growth: Skilled workers and innovation attract businesses and boost local economies.

- Sustainability: Research focuses on eco-friendly practices, reducing manufacturing’s environmental footprint.

- Community Engagement: Outreach programs and partnerships strengthen ties and highlight manufacturing’s role in local development.

Conclusion

Learning factories create a dynamic ecosystem where education and industry collaborate to solve real-world problems, advance technology, and contribute to economic and environmental sustainability. They prepare the next generation of manufacturing professionals while driving progress across the sector.

7. Challenges and suitable Solutions

Learning factories face challenges that require proactive solutions to maintain their impact and sustainability.

Challenges

- High Setup Costs: Significant investment in equipment, technology, and infrastructure.

- Keeping Pace with Technology: Regular updates needed to match rapid manufacturing advancements.

- Industry-Academia Alignment: Difficulty in adapting curricula to evolving industry needs.

- Sustainability: Balancing financial and environmental management with educational goals.

- Student Engagement: Maintaining motivation in demanding technical environments.

Solutions

- Securing Funding and Partnerships

- Leverage government grants, industry sponsorships, and alumni contributions.

- Updating Curriculum and Technology

- Form industry advisory boards, design modular curricula, and train educators regularly.

- Strengthening Industry Collaboration

- Foster communication, joint workshops, and real-world student projects.

- Ensuring Sustainable Operations

- Optimize resources, adopt energy-efficient practices, and integrate sustainability into curricula.

- Boosting Student Engagement

- Emphasize hands-on learning, career services, and mentorship programs.

Conclusion

By addressing these challenges with targeted strategies, learning factories can sustain their role as vital hubs for manufacturing education and innovation, benefiting students, industry, and society.

8. Future of Learning Factories

The future of learning factories promises innovation and transformation, reshaping manufacturing education and industry practices.

1. Integration of Emerging Technologies

- Advanced Robotics: Incorporating collaborative robots and autonomous systems for hands-on training in modern automation.

- AI and Machine Learning: Enhancing predictive maintenance, quality control, and process optimization through data-driven insights.

- VR and AR: Revolutionizing training with immersive simulations and remote collaboration.

2. Emphasis on Sustainability

- Green Manufacturing: Training students in eco-friendly materials, energy-efficient processes, and circular economy principles.

- Renewable Energy: Incorporating solar and wind power to reduce environmental impact and teach energy integration.

3. Global Collaboration

- International Partnerships: Facilitating global knowledge exchange and joint research projects.

- Virtual Platforms: Enabling real-time collaboration across borders for students, educators, and industry leaders.

4. Personalized Learning

- Adaptive Learning: AI-driven platforms tailoring resources and assessments to individual needs.

- Flexible Pathways: Modular courses and certifications allowing students to design their educational journey.

5. Industry 4.0 and Beyond

- Cyber-Physical Systems: Preparing students to manage interconnected systems and digital twins for smart manufacturing.

- Digital Transformation: Emphasizing cloud computing, big data, and cybersecurity in manufacturing processes.

6. Lifelong Learning

- Upskilling Opportunities: Offering ongoing education through workshops, online modules, and executive programs.

- Professional Certifications: Providing industry-recognized credentials for skills acquired in learning factories.

Conclusion

The evolution of learning factories will be defined by advanced technologies, sustainability, global collaboration, personalized education, and alignment with Industry 4.0. These innovations will ensure that learning factories remain essential for preparing future manufacturing leaders and driving the industry toward efficiency, sustainability, and competitiveness.

9. How to setup a Learning Factory

Establishing a learning factory requires careful planning, strategic partnerships, and a clear vision for integrating education with industry needs. Here is a summarized guide on how to set up a learning factory:

1. Define Objectives and Scope:

Identify the goals and objectives of the learning factory, such as enhancing practical education, fostering innovation, and addressing industry challenges.

Determine the scope of the learning factory, including the target audience (students, professionals), focus areas (e.g., advanced manufacturing, robotics), and types of programs (courses, workshops, research projects).

2. Secure Funding and Resources:

Assess the financial requirements for setting up and operating the learning factory, including equipment, facilities, and personnel costs.

Seek funding from government grants, industry partnerships, alumni donations, and educational institution budgets. If you are based in Europe, see EIT Manufacturing for funding programs.

Explore options for in-kind contributions, such as equipment donations from industry partners.

3. Curriculum Development:

Design a curriculum that integrates theoretical knowledge with practical skills relevant to current industry practices.

Collaborate with industry advisors to ensure curriculum alignment with industry needs and standards.

Develop modular courses that allow flexibility and scalability in program offerings.

4. Infrastructure and Equipment:

Identify the necessary infrastructure, such as workshops, labs, classrooms, and collaborative spaces.

Procure state-of-the-art equipment and technologies that reflect current and future manufacturing trends. See the Edquip section of Manufacturing Training Systems to review product types, or to better understand how to manage technical learning environments, download our free eBook.

Ensure facilities are designed for safety, efficiency, and accessibility for students and staff.

5. Industry Partnerships:

Establish partnerships with local, national, and international manufacturing companies, research institutions, and industry associations.

Form industry advisory boards to provide guidance on curriculum development, research projects, and industry trends.

Collaborate on joint projects, internships, and co-op programs to enhance student learning and industry engagement.

6. Faculty and Staff Recruitment:

Recruit qualified faculty members with expertise in manufacturing, engineering, robotics, and related fields.

Hire technical staff to support equipment maintenance, lab operations, and student projects.

Provide professional development opportunities for faculty to stay updated on technological advancements and teaching methodologies.

7. Student Recruitment and Support:

Develop outreach programs to attract students interested in manufacturing education.

Provide comprehensive support services, including career counseling, internship placement, and academic advising.

Foster a supportive and inclusive learning environment that encourages collaboration, creativity, and lifelong learning.

8. Operational Planning and Management:

Develop operational policies and procedures for facility use, safety protocols, and equipment maintenance.

Implement sustainable practices for resource management, energy efficiency, and waste reduction.

Establish partnerships with local communities and stakeholders to promote community engagement and support.

9. Continuous Evaluation and Improvement:

Implement mechanisms for ongoing evaluation of program effectiveness, student outcomes, and industry partnerships.

Collect feedback from students, faculty, industry partners, and stakeholders to identify areas for improvement.

Adapt curriculum, facilities, and programs based on feedback, industry trends, and technological advancements.

10. Promotion and Recognition:

Market the learning factory to prospective students, industry partners, and stakeholders through various channels.

Showcase student projects, research outcomes, and industry collaborations to demonstrate the impact and relevance of the learning factory.

Seek accreditation and recognition from relevant educational bodies, industry associations, and government agencies to enhance credibility and attract support.

Setting up a learning factory requires dedication, collaboration, and a commitment to excellence in manufacturing education. By following these steps and continuously adapting to meet evolving industry needs, learning factories can prepare future generations of skilled professionals and contribute to the advancement of manufacturing practices and innovation.

10. Learning Factory Resources

Below a few links to further resources which might be suitable for your search:

Organizations:

- International Association for Learning Factories (IALF)

- International Academy for Production Engineering

Examples of existing learning factories:

- Penn State Engineering Learning Factory

- TU Darmstadt: Process Learning Factory CiP

- Technische Universität Wien: Pilot Factory

- Stellenbosch University: Stellenbosch Learning Factory

- University of Windsor: iFactory

- Technische Universität München: Learning Factory for Lean Production (LSP)

- Ruhr-Universität Bochum: LPS Learning Factory

- Hochschule Reutlingen: Werk150

- Dresden University of Technology: Process-to-Order Lab (P2O-Lab)

Manufacturing related product categories at Edquip:

- Manufacturing Training Systems

- Industrial Maintenance Training Equipment