Hydraulics Lab Equipment & Training Systems

Sort by

Learn more about Hydraulic Training Equipment

In the below section you will learn about hydraulics training equipment and how they are used to teach different topics of hydraulics. We will also cover definitions, best practices for teaching and how to buy equipment the best way.

What is Hydraulics?

Hydraulics describes the concept of putting liquids (such as oil, water or similar) under pressure to transfer power from one place to another.

Hydraulics machines typically transfer power through relatively small cylinders, tubing and hoses, considering the amount of power that goes through such systems.

Common industry applications are heavy construction vehicles, agricultural machines, mining equipment, material handling through bending, pressing, cutting, forming etc. in manufacturing.

Read about how Edquip together with two technology integrators have implemented Hands-on training in Marine Hydraulics at the Sharjah Maritime Academy in UAE.

Why teach Hydraulics?

Hydraulics machinery and industrial applications with hydraulic components are common in our society, which means that there is a lot of work for installment, maintenance, and repair of hydraulic equipment. The profession quickly bounced back to low levels of unemployment after the last economic crisis.

About 40% of hydraulic technicians have a high school diploma degree, 21% an associates degree and 19% a bachelor’s degree. Most students majored in automotive technology, industrial machinery, or aviation. Zippia writes that the income of a hydraulic mechanic range between $36,525 on the lower end with a high school diploma to $43,023 for someone with a college or associates degree.

Hydraulics training best practices

Good hydraulic training focuses on teaching hands-on skills, some of the most looked for are the following:

- Hand Tools (operating hand tools and hydraulic equipment)

- Electrical Systems (diagnostics, trouble shooting and maintenance of electrical systems)

- Safety Procedures (capability to follow organizational safety instructions)

- Test Equipment (operation and maintenance of hydraulic test equipment)

- Heavy Equipment (assembly, maintenance and repair of motors and pumps)

As we can observe, hydraulics mechanics and technicians will work with machinery and heavy equipment in industrial environments such as factories, building sites, garages, oil platforms, mines etc.

The main way to decrease hydraulics work-based accidents is to have students learn to safely operate tools and equipment in a hands-on manner already before entering the workforce.

What is Hydraulic Training Equipment?

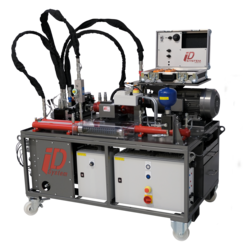

Hydraulic training equipment is a “didactic tool” or “instructional technology” used by teachers and professors in vocational and technical training, in order to teach the concepts of hydraulics in a hands-on and engaging way.

Hydraulic training equipment is a combination of hardware, software and content which helps the students of hydraulics to learn by doing, assembly, trouble shooting and fault diagnostics of hydraulic systems.

Hydraulic training equipment is used in vocational high schools, community colleges, TVET colleges, polytechnics, universities, corporate training centers etc.

Buying Hydraulic Training Equipment

Here at Edquip you can find different types of hydraulic training equipment from various producers. These training tools all have different didactic approaches on how they choose to teach the subject, but they all consist of a combination of hardware, software and content.