CNC Training Machines for Education

Sort by

Learn more about using CNC training machines

In this section you will learn more about using CNC in technical and vocational education and training (TVET), also called career and technology education (CTE).

Users of CNC Training Machines

The majority of CNC lab equipment used for educational purposes can be found in different types of complexity at different types of institutions, such as per below:

- Vocational & technical schools

- Community colleges

- TVET colleges

- Polytechnics

- Universities

- Government Training Centers

Often the educational programs including CNC machining into their learning environments are referred to as:

STEM programs

A STEM program is an educational program at primary or secondary education aiming to engage the students in Science, Technology, Engineering & Mathematics in a holistic and cross departmentalized way. The best STEM programs let students learn by actively engaging in real world and personally engaging projects through a problem-based learning approach (PBL).

FAB labs

A FABLAB (fabrication lab) is a small workshop equipped with digital manufacturing tools aimed at teaching concepts for personalized products. The methodology spun out from MIT media lab in early 2000 and has quickly spread all across the globe. Today the worldwide community of Fablabs is managed through The Fab Foundation.

Topics covered with CNC training machines

The learning experience covered with CNC machines is hands-on, problem based and very engaging for most students. Teaching CNC can be done through various curriculums such as:

- Wood or metal fabrication

- Electronics & robotics

- Industrial arts

- Engineering design process

Benefits of using CNC in Education

The process of teaching CNC has various benefits for the students such as:

- Increased engagement: when students get ownership of their own learning experience, especially when taught in a PBL approach.

- Increased content retainment: course materials stick better with students that get to work through topics in a hands-on manner.

- Critical thinking: when students are taught to focus on a desired outcome rather than memorizing information, critical thinking is improved.

- Real world experience: students get a real-world experience when taught and mentored by instructors who come and have experience of the technology directly from the industry.

- Workplace safety: most workplace accidents come from incorrect usage of tools and machines, so students who learn to properly handle machines and equipment early have a lower risk of future workplace accidents than students with inadequate training.

Types of CNC Training Machines

CNC machines are grouped as subtractive manufacturing machines, since they remove material to create parts, as opposed to 3D-printers which are grouped as additive manufacturing, since they build objects layer by layer. What these two fields have in common is that a pre-programmed computer software dictates the movement of the machines.

Computer Numerical Control (CNC) machines come in different sizes, shapes, cost levels and they are designed for different purposes:

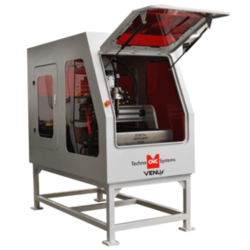

CNC Milling machine

A CNC milling machine utilizes computer controls to cut various materials in three dimensional shapes. In a CNC milling machine the workpiece is kept stable in a vice, while the cutting tools (spindle) rotates on a three to six axis’s configuration, to create precise cuts.

CNC Lathe

In a CNC lathe the workpiece is rotating and a static blade is applied to the surface of the material to cut into and form the workpiece. CNC lathes are essentially improvements upon manual lathes and have fewer axis than a milling machine.

CNC Router

A CNC router is versatile and used for cutting various types of materials, such as steel, aluminum, wood, composites, plastics or foam. Most routers operates a material in all three dimensions. CNC routers are great for smaller projects, prototyping and specifically for education and training.

CNC Plasma cutter

A CNC plasma cutter blows gas from its nozzle at a very high speed which produces plasma, in a temperature range of 10,000 – 50,000 degrees. A plasma torch cuts through heavy materials such as metals or steel, while it blows away any molten metal. Plasma cutters only work in two dimensional shapes.

CNC Laser cutter

CNC Laser cutters are similar to plasma cutters in that they only work in two dimensional shapes. Laser cutters are mostly used for cutting lighter metals, plastic or hardwood.