Technical Training Equipment

Sort by

Learn about Technical Training Equipment

What is Technical Training Equipment?

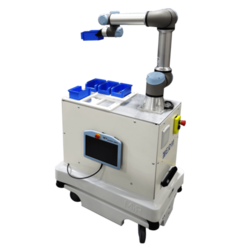

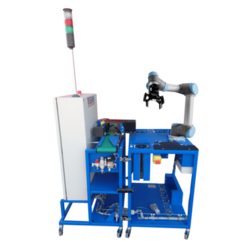

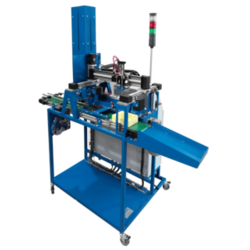

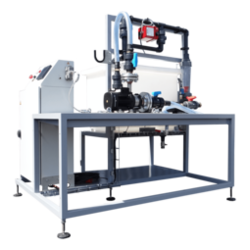

Technical training equipment refers to a set of tools, devices, machines, and instruments used in educational and training settings to provide hands-on experience and practical skills development in specific technical fields. This type of equipment is designed to simulate real-world scenarios and industry-specific tasks, allowing individuals to gain the necessary skills for a particular technical profession.

What types of Technical Training Equipment exist?

The specific equipment used can vary widely depending on the field of study. Here are a few examples of technical training equipment:

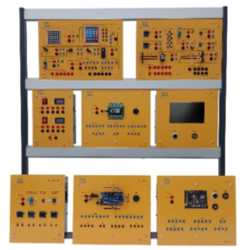

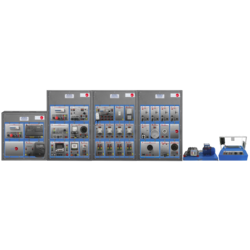

- Electrical Training Boards: Boards equipped with electrical components, circuits, and wiring systems to teach and practice electrical installation, troubleshooting, and maintenance.

- Automotive Training Simulators: Simulators that mimic the components and systems of vehicles, allowing students to practice diagnostics, repair, and maintenance of automotive systems.

- Welding Machines: Equipment for training in welding techniques, including welding machines, safety gear, and materials for practicing various welding processes.

- Computer Labs: Computers, servers, networking equipment, and software used for hands-on training in information technology, networking, and computer programming.

- Plumbing Training Kits: Kits containing plumbing fixtures, pipe fittings, and tools for hands-on training in plumbing installation, repair, and maintenance.

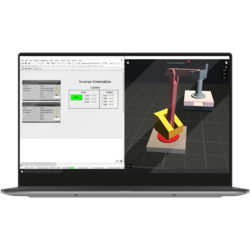

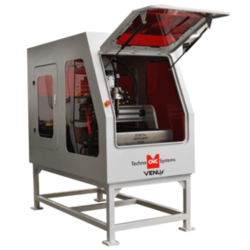

- CNC Machines: Computer Numerical Control (CNC) machines for training in precision machining and manufacturing processes.

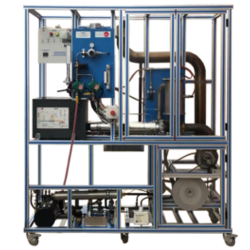

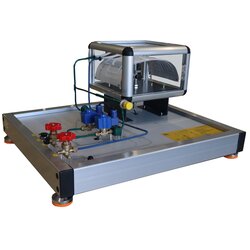

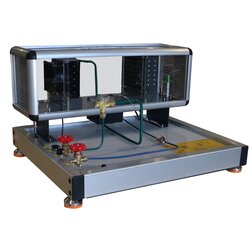

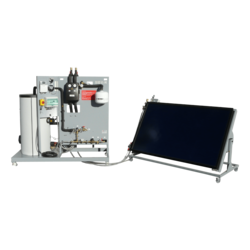

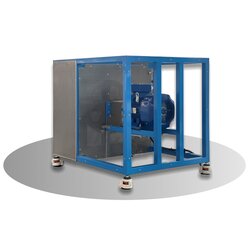

- HVAC Training Equipment: Units that simulate heating, ventilation, and air conditioning systems for practical training in HVAC installation, maintenance, and repair.

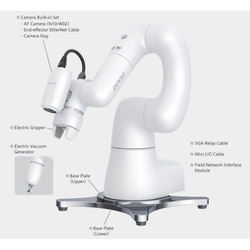

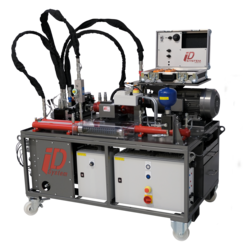

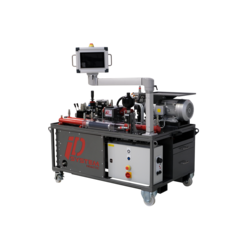

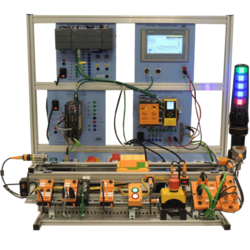

- Manufacturing Training Systems: Training systems that simulate industrial processes and automation, allowing individuals to learn about programmable logic controllers (PLCs) and control systems.

- Medical Simulators: Simulation equipment for healthcare training, including patient simulators, diagnostic tools, and medical imaging devices.

- Construction Training Tools: Tools and equipment used in construction training programs, such as power tools, safety gear, and materials for hands-on practice in construction techniques.

- Cosmetology Training Stations: Stations equipped with beauty and cosmetology tools for hands-on practice in hairdressing, skincare, and salon services.

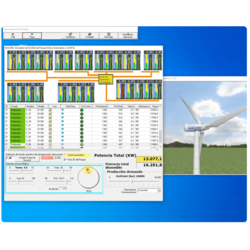

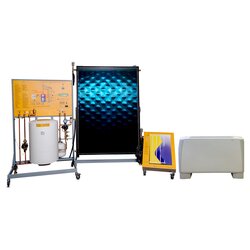

- Renewable Energy Lab Equipment: Kits designed for training in renewable energy technologies, including solar panels, wind turbines, and energy storage systems.

Technical training equipment plays a crucial role in bridging the gap between theoretical knowledge and practical application, providing learners with the skills and confidence needed in various technical professions. The equipment is often tailored to specific industries and designed to meet the practical requirements of the workforce.

Which types of education institutions use Technical Training Equipment?

Technical training equipment is commonly used in vocational schools, technical institutes, apprenticeship programs, and other educational institutions that focus on preparing individuals for careers in various technical and skilled trades. Below a few examples:

- Vocational Schools: Specialized institutions that offer practical, hands-on training programs in specific trades, such as automotive technology, welding, or HVAC.

- Technical Institutes: Educational institutions that emphasize technical education, offering programs in engineering technology, electronics, and other applied sciences.

- Community Colleges: Many community colleges provide technical training programs that lead to certificates or associate degrees in fields such as information technology, healthcare, or manufacturing.

- Career and Technical Education (CTE) High Schools: High schools with a focus on career and technical education, providing students with opportunities to gain practical skills alongside traditional academic coursework.

- Apprenticeship Programs: Organizations and institutions that run apprenticeship programs, combining on-the-job training with classroom instruction using technical training equipment.

- Trade Schools: Private institutions that specialize in providing training for specific trades, offering programs in areas such as plumbing, cosmetology, or electrical work.

- Adult Education Centers: Centers that offer technical training and retraining programs for adults looking to acquire new skills or transition to new careers.

- Military Training Centers: Military training centers often include technical training programs for various technical roles within the armed forces.

- Online Education Platforms: Some online platforms offer virtual technical training programs, providing interactive simulations and virtual labs for skill development in fields like programming, cybersecurity, or IT.

- Corporate Training Centers: Companies and organizations may have training centers equipped with technical training equipment to develop the skills of their workforce in areas such as manufacturing, maintenance, or technology.

- Prison Education Programs: Some correctional facilities provide technical training programs to inmates, offering them skills that can be useful upon reintegration into society.

- Research and Development Centers: Institutions involved in research and development, particularly in engineering and technology, may use technical training equipment for experimental purposes and skill development.

The use of technical training equipment is diverse and spans various educational settings, ranging from high schools to specialized vocational institutions. These institutions aim to equip individuals with the practical skills and knowledge necessary for success in specific technical professions and trades.

How to choose the right Technical Training Equipment?

Choosing the right technical training equipment is crucial to providing effective hands-on learning experiences and preparing individuals for careers in specific technical fields. Here are key considerations to guide the selection process:

- Define Training Objectives: Clearly define the objectives of the technical training program. Identify the specific skills and competencies that participants need to develop.

- Align with Industry Standards: Ensure that the equipment aligns with industry standards and practices. It should reflect the tools and technologies commonly used in the field to provide relevant and up-to-date training.

- Quality and Durability: Invest in high-quality equipment that is durable and can withstand regular use in a training environment. Quality equipment tends to provide more accurate and reliable learning experiences.

- Safety Features: Prioritize equipment with safety features to ensure the well-being of participants. Safety should be a top consideration, especially when dealing with tools and machinery.

- Ease of Use: Choose equipment that is user-friendly and easy to operate. This is important, especially in educational settings where participants may have varying levels of experience.

- Scalability: Consider the scalability of the equipment. Choose tools and machines that can accommodate different levels of complexity, allowing for progressive skill development.

- Maintenance and Support: Evaluate the maintenance requirements of the equipment. Choose equipment for which spare parts are readily available, and ensure that there is good customer support in case issues arise.

- Integration with Technology: Consider whether the equipment can integrate with technology, such as computer software or simulation tools, to enhance the training experience.

- Budget Considerations: Establish a budget for technical training equipment and seek options that offer the best value for the investment. Consider both the upfront costs and long-term costs, including maintenance and potential upgrades.

- Reviews and Recommendations: Research and read reviews from other technical training programs or institutions that have used the equipment. Recommendations and feedback from peers can provide valuable insights.

- Customization Options: Choose equipment that allows for customization to meet the specific needs of the training program. This could involve adjusting settings, adding attachments, or incorporating industry-specific components.

- Environmental Impact: Consider the environmental impact of the equipment, including energy efficiency and sustainable manufacturing practices, to align with institutional values and environmental responsibilities.

By carefully considering these factors, educational institutions and training programs can make informed decisions when selecting technical training equipment. The goal is to provide participants with practical, industry-relevant skills and prepare them for success in their chosen technical professions.