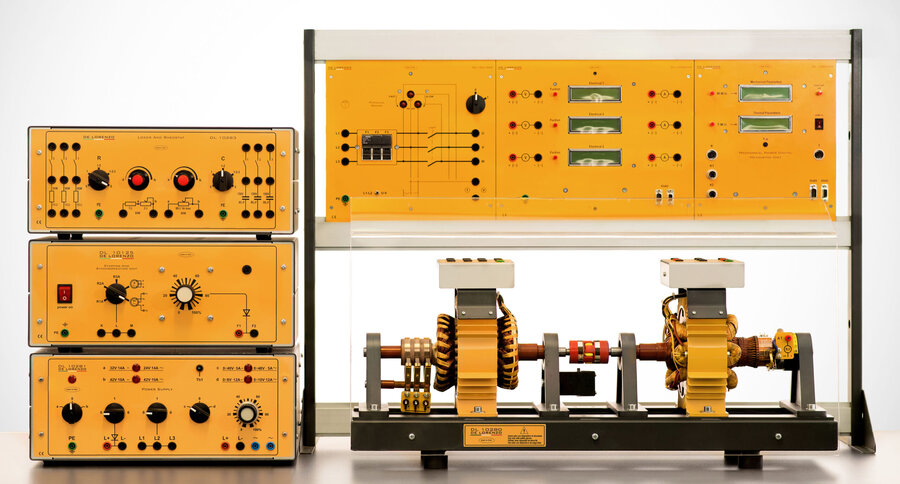

Semi-Automatic Electric Machines Laboratory With Artificial Intelligence (DL OPENLAB-SA-AI)

PL-691139

The DL OPENLAB-SA-AI offers a “first glance” at the vast and complex world of electric machines. The main characteristic of this laboratory is its "open" structure, where rotor windings, stator windings and brushes are completely exposed to perform didactic experiences such as the analysis of magnetic fluxes and magnetic fields. In this way, the students can learn in detail the internal construction and assembly of different types of electrical machines and carry out practical tests for the acquisition of their operating characteristics.

This modular system operates at low voltages providing a safe hands-on training environment with the addition of the plexiglass protection preventing direct contact with the rotating electrical machines to avoid injury. It includes software developed in LabVIEW that communicates with the main measuring modules in the system to acquire electrical and mechanical values.

AI Module Integration: To enhance the learning experience, an AI module is incorporated to analyse data collected from the experiments. This module provides real-time feedback and simulations based on the students’ inputs and experiments. By leveraging machine learning algorithms, the AI could identify patterns in the operating characteristics of different machines and suggest optimizations or troubleshooting techniques. This would not only deepen students’ understanding of electrical machines but also equip them with modern tools used in industry for data analysis and predictive maintenance.

Ideal for 4 students to work simultaneously, Vocational and technical schools. Applicable to courses in: Magnetism and Electromagnetism, Electromechanics, Electric machines, Power Engineering.

DIDACTIC EXPERIENCES AND APPLICATIONS

The DL OPENLAB-SA-AI trainer is a hands-on learning platform that provides a comprehensive course on electrical machines. It introduces the basic concepts of electrical machines construction starting from the electromagnetism principles with the analysis of magnetic fields and fluxes, until more advanced experiments with the characterization and the efficiency analysis of rotating machines in different working conditions.

Through this system, it is possible to assemble the most common types of electrical machines found in the industry to carry out didactic experiences both with the basic configuration and with the one enhanced with ARTIFICIAL INTELLIGENCE.

EXPERIMENTS FOR BASIC CONFIGURATION:

- Study of the magnetic field,

- Principles of the electromagnetic induction,

- Separately shunt, series and compound excited DC motors,

- Separately shunt, series and compound excited DC generators,

- DC motor and DC generator with permanent magnet stator,

- Induction motors: three-phase slip ring and squirrel cage, single-phase repulsion and with capacitor,

- DAHLANDER connection,

- Synchronous three-phase motor, induction regulator and phase shifter, alternator, and universal motor.

EXPERIMENTS FOR CONFIGURATION ENHANCED WITH ARTIFICIAL INTELLIGENCE MODULE:

- Signal Processing,

- Predictive Analysis,

- Supervised Machine Learning (SML),

- Expert Systems,

- Neural Networks,

- Optimization through Genetic Algorithms,

- Reinforcement Learning,

- Internet of Things (IoT).

DATA ACQUISITION AND PROCESSING SOFTWARE (DL OPNLAB_DAS)

The DL OPENLAB_DAS is software developed for the acquisition and displays the data of the DL OPENLAB-SA-AI laboratory. It is developed in LabVIEW and communicates with the instruments (DL 10282NF and DL 10055NF) via serial port using the Modbus protocol and acquires mechanical data (speed and torque) as well as electrical data (AC and DC, Voltage, current and Power).

SOME FEATURES OF DL OPENLAB_DAS

- For each experiment, acquiring data by setting number of measurements and accuracy.

- Tracing the characteristic curves of the elements under study using the acquired data.

- Exporting data in .xls file for further analysis.

ELECTRICAL MACHINES SMART SIMULATOR SOFTWARE (DL OPENLAB-SSEM)

The DL OPENLAB-SA-AI includes the smart simulator DL OPENLAB-SSEM. It is a performant new generations educational course that permits a complete and innovative didactic experience on electric machines in a virtual reality environment. It has been developed to reproduce the features and behaviours of the real electric machines’ laboratory. The didactic experience includes electric machines assembly (rotos, stators, supports, couplers), wiring the machines following the software instructions, the students submit them to different working conditions and make measurements to study its behaviour.

SOME FEATURES OF DL OPENLAB-SSEM

- VIRTUAL SIMULATION OF ELECTRIC MACHINE LABORATORY: Students can replicate experiments of the real system away from the classroom like a home environment.

- AUTOMATIC VALIDATION OF STUDENTS’ TASKS: the software automatically verifies if the student has successfully completed each task to allow him/her to go ahead with the next one.

- TRACKING OF STUDENTS’ PROGRESS: the teacher can verify the students’ progress any time consulting the specific summary in the software or exporting it to a spreadsheet.

LABORATORY COMPOSITION (DL OPENLAB-SA-AI)

CODE

- DL 10280 Set of assembled machines

- DL 10280MP Permanent magnet stator

- DL 10281 Power supply module

- DL 10282NF Electrical measurement module

- DL 10055NF Mechanical power digital measuring unit

- DL 2006D Load cell

- DL 10283 Loads and rheostat module

- DL 10284 Adapter bracket

- DL 10285 Locking and rotatable device

- DL 10185 Pole changing unit

- DL 10310NF Parallel board module

- DL 10300A Electromagnetic brake

- DL 10116 Star-delta starter

- DL 10125 Starting and synchronization unit

- DL AI-MODULE Artificial Intelligence module

- DL 2100-2L Two-level work frame

- DL OPENLAB_DAS Data acquisition and processing software

- DL OPENLAB-SSEM Electric machines smart simulator software

EXPERIMENTS LIST OF THE ENHANCED CONFIGURATION (WITH DL AI-MODULE)

- Signal Processing: Voltage, current, and torque signal analysis to optimize the control of electrical machines.

- Predictive Analysis: Prediction of wear and failures in motors and generators.

- Supervised Machine Learning: Prediction of the behaviour of electrical machines under different load conditions.

- Expert Systems: Expert system for managing electrical machines and optimizing their performance.

- Neural Networks: Modelling the behaviour of motors and generators to predict performance.

- Optimization through Genetic Algorithms: Optimization of motor and generator efficiency under various conditions.

- Reinforcement Learning: Dynamic adjustment of operational parameters of electrical machines to optimize their performance.

- Internet of Things (IoT): Use of IoT sensors to monitor and adjust the parameters of electrical machines in real-time.

DESCRIPTION OF SOME EXPERIMENTS OF THE PREVIOUS LIST

- Three-phase squirrel cage motor, 2 poles, 24 VΔ: This experiment studies the behaviour of the three-phase squirrel cage motor in load condition with the stator windings connected in delta.

- Three-phase squirrel cage motor, 2 poles, 42 VY: The main objective of this experiment is to study the characteristic curve of a three-phase squirrel cage motor with the stator winding connected in star by performing a direct test using an electromagnetic brake.

- Three-phase squirrel cage motor, 2 poles, 24 VΔΔ: Applying the same concepts studied up to this point, the students can plot the load characteristics of the three-phase squirrel cage motor connected in double delta.

- Three-phase squirrel cage motor, 2 poles, 42 VYY: Flowing the same procedure with the stator winding connected in double star, the student will trace the curves for the absorbed current I, the power factor cos, the speed n and the efficiency as a function of the output power P.

- Three-phase squirrel cage motor, 4 poles, 24 VΔ: In addition to recording the operation characteristics of the motor, the students will learn how to start the motor using a star-delta starter.

- Three-phase squirrel cage motor, 4 poles, 42 VY: In this experiment, the student will learn the load operation of a three-phase motor with 4 poles.

- Three-phase DAHLANDER motor, 4/2 poles, 42VΔ /YY:In previous experiments, it has been demonstrated that by changing the number of poles it is possible to vary the speed of a squirrel cage motor. The students will learn about two-speed DAHLANDER motor configuration and its operation.

- Split phase motor: The split phase motor, also known as a resistance, start motor, has a single cage rotor and its stator has two windings known as main winding and started winding. The main objective of this experiment is to study the characteristics of the motor with the main winding only, and to draw the curves of current I, efficiency η, torque C, output power P and power factor.

- Capacitor start and run motor: The objective is to study the characteristics of the motor with permanently connected capacitor. The students will learn how to properly select and connect a capacitor to the auxiliary windings so that the current trough the main winding lags behind the current of auxiliary windings by an angle on 90°.

- Three-phase motor with wound rotor, 2 poles, 42 VYY: The student will record the load characteristics of the motor with a wound rotor and the stator connected in double star. With the knowledge acquired up to this point, it will be easy to draw the diagram of mechanical characteristic M = f(n) and to observe the behaviour of an induction motor with a different type of rotor.

- Phase shifter: The objective is to study how the phase between the stator and rotor voltages varies in function of the rotating angle and identify the null phase shift condition using Lissajous’ ellipse by setting the oscilloscope to XY mode.

- Induction regulator: The objective is to study the operation of a three-phase voltage regulator. By using a locking and rotating module with a graduated disc, the rotor can be turned by means of the hand-wheel until the load current results null with minimum indication of the voltmeter. The student will measure the absorbed current at constant load and draw the current and voltage curves as a function of the angular phase shift.

- Three-phase synchronous induction motor, 2 poles, 42 VΔ: This experiment studies how to start and synchronize the induction motor using the starting rheostat and study the load characteristics of the motor at synchronous speed.

- Three-phase synchronous induction motor, 2 poles, 24 VΔΔ: Following the same procedure as in previous experiment, the diagram of the absorbed current I, the power factor cos and the efficiency as a function of the output torque c will be traced with the stator wired in delta-delta configuration.

- DC motor with separate excitation: Now is time to work with DC motors. First application refers to a separately excited DC motor, where the field winding is powered by an external independent source. The DC motor operation characteristics will be studied as a function of the excitation voltage.

- DC motor with shunt excitation: By performing this experiment, the student will learn how to connect that the armature and field windings in parallel and you compare the behaviour with the previous experiment.

- DC motor with series excitation: Unlike in the DC shunt motor, the DC series motor has very poor speed regulation. The main objective of the experiment is to draw the characteristics of the output power P, the speed n, and the efficiency as a function of the absorbed current I.

- DC motor with compound excitation, long shunt: By combining the operational characteristic of both the shunt and series excited DC motor we obtain the one of the DC compound excitation motor. The operation of the motor is studied with cumulative and differential excitation.

- DC motor with compound excitation, short shunt: This experiment shows why the compound motor responds better to heavy load changes than a shunt motor.

- Study of single-phase series motor: Single phase series motor, also known as a universal motor, is a rotating machine similar to a DC motor but designed to operate either from DC or single-phase AC.

- Study of repulsion motor: The repulsion motor combines a stator of a single-phase motor with a rotor similar to that of a DC motor. The main benefit of the repulsion motor is that the armature is separated from the line. The main objective of this experiment is to record its operation characteristics.

- Measure the windings resistance of the alternator: This experiment calculates the voltage drops across the rotor winding resistance of an induction motor using Ohm’s law. The winding resistance value of the alternator is useful to calculate the conventional efficiency.

- No-load test of the alternator: The main objective of this experiment is to determine the mechanical and iron losses of the alternator and to record its magnetization characteristic using a DC motor as prime mover.

- Short-circuit characteristic of the alternator: The short-circuit test of the synchronous generator provides information about its current capabilities. It is performed by driving the generator at its rated speed while the terminals of the armature winding are shorted. This characteristic diagram is essential for the application of the indirect testing method of the alternator.

- Load test of the alternator: This test compares the behaviour of a synchronous generator connected to a variable external load with its no-load operation.

- Conventional efficiency of the alternator: The conventional efficiency of a synchronous machine is determined by measuring the losses operating at different power factors, using the results from the previous experiments.

- Parallel connection of the alternator with the main: This experiment studies an operation which is frequently performed in a power station. The synchronization of a generator consists of electrically coupling the generator output to another source of electrical energy and operating the generator such that its output adds to the other source.

- Study the “V” curve of the synchronous motor: The V-curve of a synchronous machine shows its performance in terms of variation of the armature current with the field current when the load and the input voltage of the machine are maintained constant. The students will trace different V curves for particular resistant torque applied to the motor axis.

- Measure the windings resistance of the DC generator: This experiment demonstrates how measuring the internal resistance of a DC machine can be used to establish the integrity of the machine windings and internal connections.

- Test of the no-load motor (Swinburne): In order to design rotating DC machines with higher efficiency, it is important to study the losses occurring in them. Swinburne’s method consists of operating a dynamo as a DC motor with no load to determine its mechanical and iron losses. This is done by increasing the armature voltage U while measuring the armature current Ia and the excitation current Ie.

- Magnetization characteristic of a DC Generator: This experiment studies the magnetization characteristic of a separately excited DC generator using a three-phase synchronous motor as prime mover.

- Study of separate excitation dynamo: The main objective of this experiment is to record of the external and regulation characteristics of a separate excitation generator to determine its conventional efficiency. This is done by measuring the output voltage U as a function of the load current, with constant excitation current Ie.

- Study of shunt excitation dynamo: The previous experiment is replicated with a different configuration of the DC generator. Using the results from the previous experiments, the student will plot the external and regulation characteristic of the generator connected in shunt.

- Study of series excitation dynamo: Determining the external characteristic of a DC generator connected in series is to observe how the voltage slightly drops as the load increases. Students will use these results to calculate the conventional efficiency of the dynamo.

- Study of compound excitation dynamo: This experiment follows the same procedure as the previous ones with the generator in compound excitation connection. After performing this last experiment, the students will be able to make comparative analyses between all the different DC generator configurations.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review