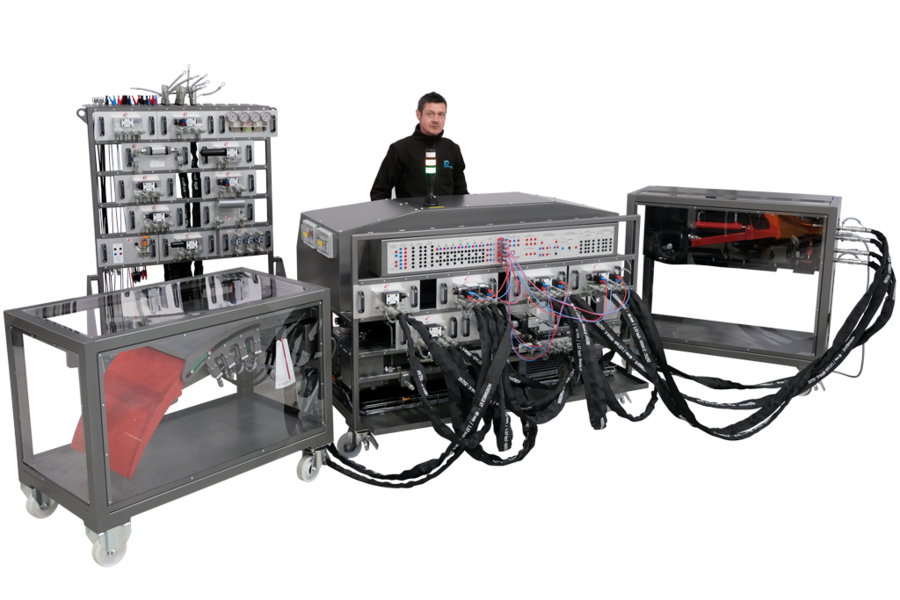

Aeronautical Maintenance Training System (AERO)

PL-946998

This didactic equipment has been specially designed for the learning of hydraulic aeronautical maintenance.

The purpose of this bench is to provide the best learning and safety conditions to learners while combining to these didactic equipments some hydraulic industrial components suitable for the aeronautics requirements.

These didactic equipments ensure the learners and trainers’ safety as well as avoid them to be in contact with high toxicity hydraulic fluids and high pressures as the ones met on aircrafts.

Students practice on a didactic aeronautical laboratory, specially designed with hydraulic components from high branded industrial technology which has the advantage to be less expensive than aeronautical equipments. They learn the maintenance of airplanes/helicopter hydraulic circuits in a playful approach.

The Aérocampus of Bordeaux (south western France), experts in aeronautics maintenance have thus helped us to design this electro-hydraulic control desk and its operative parts which allow to place learners in situation with a didactic material taking again the specificities of the aeronautical field.

We relied on the skills and experience of a teacher graduated from the French National Education and former mechanical engineer sailing in the French Air Force Yoann Gac, to develop this complete training equipment.

This educational aeronautical bench enables to develop the following skills:

- Using a technical documentation

- Taking into account the hydraulic dangers

- Securing an hydraulic circuit

- Preparing a technical intervention

- Installing and removing subassemblies

- Tuning subassemblies

- Running some trials

- Performing troubleshooting and repairs

- Performing checks further to an intervention

- Monitoring a part of an aircraft

- Communicating information in an aeronautics environment

FULL TRAINING SYSTEM PARTS

Control and wiring desk

- 1 power unit with 2 hydraulic circuits + safety control

- Safety control with hand pump

- 70 Liters steel tank with breather screw, lead-sealed pressure relief valve 120 bar, visual and electric level, filter

- CETOP 3 function block with 4/2 distributor and secondary pressure relief valve

- Adjusted 80 bar secondary circuitry allowing taking over

- Safety control with hand pump PM50 12/25/45 and with stick

- Cooling circuit 2015 K-380V with safety thermostat

ECAM visual PLC screen

- This new generation industrial HMI automaton represents an Ecam screen that you usually find in aircraft cockpits.

- You will be able to visualize during the operating cycles of the operative parts, landing gear and flap (Wheel and Flapi), the proper functioning of the movement sequences thanks to the sensors connected to the PLC and the LEDs on the landing gear & flap control panel.

- A “Hydraulic Diagram” tab will be accessible for students to apprehend the different hydraulic and electrical circuits of the equipment.

- You will also have the possibility to access to the practical work and some videos since this automaton has the particular feature of reading PDF and mp3 formats.

- A “Graph” tab is available for interpreting and analyzing curves related to flow, pressure or temperature.

Operative part: Landing gear POTA-V2

- This operative part “Landing Gear” reproduces the same gear and trapdoor opening cycle kinematic as the majority of aircraft. The trapdoor opens thanks to a hydraulic cylinder and goes to find its blocking position, then the gear, also controlled by a cylinder, unfolds and to complete the cycle, the trapdoor closes itself.

- The different steps of the cycle are validated by sensors that allow or not the control of the next movement.

Operative part: Flap POV-V2

- We have recreated the kinematics of a flap with the possibility of an “ON/OFF” hydraulic control but also in proportional control. The digital card and its software integrated in the PCA-V2 desk will allow you to control the movement of the open-loop or position-controlled flap with its linear potentiometric regulation (4 closed-loop positions with 4 position sensors).

- A compass is installed on this flap and communicates an angular displacement of this one.

Operative part: Ground hydraulic power unit GS

- This group aims to provide a adjustable pressure and flow so replacing the functions of the aircraft (It is the PCA-V2 desk which will become the aircraft), filtering and filling or emptying a hydraulic circuitry.

Storage modules:

- This components modules storage rack is the perfect accessory for our panel benches. It allows to store together in one place all hydraulic flexibles and modules you will use during your training.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review