COMPUTER INTEGRATED MANUFACTURING TRAINER – TERMINALS BLOCK (DL CIM-CT)

PL-839148

CIM (computer integrated manufacturing) is a manufacturing method, in which the entire production process is controlled by computer. This manufacturing method includes transversal applications in several didactic areas such as automation, pneumatics, electronics, mechatronics and process control.

De Lorenzo has developed station-based training systems, which allow the student to view a specific manufacturing process of an industrial production line. The trainer is a closed- loop control system based on PLC that exchanges information collected from sensors.

The version DL CIM-C integrates Conveyer belt, Linear Transfer unit, Pick and Place unit, six stations rotary table, drilling module, uploading arm, weighing module and palletizer.

TRAINING OBJECTIVES

DL CIM-C focuses on the study of the integration of the industrial sensors in process inspection as a support for manufacturing processing line. The trainer integrates the typical actuators (electric, pneumatic) into process executions. The performances of the actuators influence the quality of industrial automation functions. Together with the sensors, they ensure and multiply the value of manufacturing processes.

To study the components substations functionalities: linear transfer unit, horizontal transfer unit, pick and place unit, six stations rotary table, drilling module, uploading arm, weighing module and palletizer.

Ideal for 4 students to work simultaneously.

Vocational and technical schools.

And applicable to courses in:

HIGHLIGHTS

The trainer is a real application of industrial sensors and actuators, programmable logic control (PLC), and dedicated information and computer technologies (ICT-s).

All training topics are designed for CIM applications understanding. The sensors are a support for inspections and manipulation, the actuators run process and the PLC monitors and controls manufacturing algorithms adjusting the processes variables.

It is the basic study of Flexible Manufacturing Systems, with benefits in increasing the machines utilization, reducing the manufacturing leading time, and ensuring high flexibility scheduling.

Power supply: single phase by the mains.

Total power: 450W, 2A fuse on socket for overload and short circuit protections.

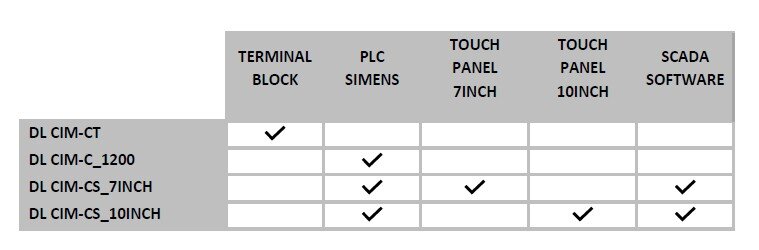

PLC included features: • SIEMENS PLC S7-1200 series Models including HMI and SCADA software is also available: • DL CIM-CS_7INCH with 7 inch HMI • DL CIM-CS_10INCH with 10 inch HMI

The CIM system is also available with an open terminal block instead of the PLC. This version allows the connection of an external controller through the 2mm terminals. For the correct operation of the system, it is recommended to use a PLC with similar or improved characteristics (INPUT/OUTPUT) as the ones provided with our standard versions (see previous notes). Order code: DL CIM-CT

Note: A compressor is needed (no less than 0.6Mpa). Module suggested: DL 8110SLZ SUBSTATIONS DETAILS CONVEYER UNIT This is a miniature model of a real time industrial conveyor system, driven by a DC motor. The operation of the conveyor is limited to single direction according to the usage. The conveyor belt rolls over two pulleys fixed on either end. The pulleys roll freely and maintain a free movement for the belt. • Length: 500 mm. • Width: 50 mm. LINEAR TRANSFER UNIT The Linear Transfer Unit is an electro-pneumatic controlled linear actuator. Magnetic switches are fixed to sense the retracted and extended position of the transfer unit. It transfers materials from the conveyor with the help of a pneumatically operated rod less double acting cylinder. • Cylinder: Pneumatic rod less (16 mm diameter, stroke length 200 mm). • Travel length: 200 mm. PICK AND PLACE UNIT It is a totally electro-pneumatic control system. There are three main parts in this unit: • a vertical arm (double acting cylinder), • a horizontal arm (double acting cylinder), and • an angular gripper (double acting angular gripper for holding work pieces). Magnetic switches are fixed to sense the retracted and extended position of the vertical and horizontal arms; so, the Pick & Place Unit transfers the material from the Linear Transfer Unit end to the next Unit with the help of the vertical arm, the horizontal arm, and the angular gripper. o Vertical travel: 80 mm. o Horizontal travel: 150 mm. o Load Capacity: 0.5Kg. CONTROL SYSTEMS: SIEMENS AND ALLEN BRADLEY PLCs There are programmable controllers that combine high performance and ease of use. Their main advantages are: • the flexibility, as they can be reprogrammed, • the possibility of their use in environments with severe working conditions, • the reliability and safety, and • the possibility of processing both digital and analogue signals. With this controller integrated into the system, the students can perform experiments commonly used in the industrial automation environment. It includes 30 digital inputs, 26 digital outputs and 2 analogue inputs. It can be programmed through the integrated Ethernet port with TIA portal software. SIX STATIONS ROTARY TABLE A Six Stations Rotary Table (also known as Rotary Indexer Supplier) consists of a horizontal circular worktable, on which the work piece is placed to be processed. The worktable is indexed to present each work piece to each work head to accomplish the sequence of machining operations. The control and driver use electrical energy. DRILLING MODULE The module simulates the function of drilling the work piece. The PLC tells the vertically double acting flat cylinder to position the drilling device near the work piece and to start the drilling device. The Drilling module is pneumatically operated with several main characteristics: • Speed: 20000 RPM • Work pressure: 0.5 ÷ 0.8 Mpa • Connection Port: 3/8 Lifting cylinder: 16 mm diameter & Stroke length 60mm Fixed cylinder: 10 mm diameter & Stroke length 10mm. UPLOADING ARM The uploading arm or horizontal Pick & Place Unit is an electro-pneumatic system in which the movement is controlled by a linear and rotary actuator. This system works as a miniature pick and place robot with a limited path application. The uploading arm is used to transfer the components or work pieces from one workstation to the other. It is pneumatically operated with main characteristics: • Lifting cylinder: 16 mm diameter & stroke length 20 mm • Rotary cylinder: 0 ÷ 180° • Load Capacity: 0.5 kg. WEIGHING MODULE The weighing module consists of two elements: the load cell and the interface circuit. The load cell generates a variable resistance value related to the weight of the object that is placed over it. The interface circuit receives processes and sends this value to the analogue input of the PLC, which determines the correspondent weight of the work piece placed over the load cell. The measuring principle: balance beam-single point weighing with: • Rated load: 0 ÷ 1 kg • Output: 0 ÷ 10V. VISION SYSTEM The vision system is a compact visual sensing equipment, which is used for quality control inspections in automated production lines. The vision system serves under the class of visual sensing methods. It basically analyses an image obtained by a video camera, displays it, and reports its characteristics to the system controller. Visual process module parameters: • Interface: Ethernet TCP/IP • Stable light source: 6 LED White Ring Light • Lens:12mm; • Sensor Type 1/3” Mono Global Shutter, 3.75μm pixel Format: 640x480 Rate: 45 • Electronic shutter • Built-in data processing system • External shooting signal • Operation mode: still shooting • Fixed method: Independent installation STACKER CRANE - PALLETIZER Stacker crane - also called palletizer; it is used for palletizing (placing) the work piece in a particular order. Our XY palletizer is a stepper motor-controlled unit. The motor controls the movement and the position of the axis of the Palletizer. For work piece handling, a suction cup is provided which is controlled using a double acting flat cylinder that will extend & retract to pick up or dispense the work piece. The driver adopts AC servo driver current loop for subdivided control, motor low speed running stable, almost no shake and noise. Suit for various CNC mechanical, robotic, cash-counting machine industries. Its main parameters are: • 2 Stepepr motor :24VDC • The stroke of axis are 110mm and y axis are 310mm • Cylinder: vertical flat type, double acting cylinder 10mm diameter and stroke 60mm. • 4 inductive sensors: Used to detect the X,Y-axis home position and the X,Y-axis ultimate limit position • Gripper: Suction cup • Operating pressure: 6 bar • Number of I/O – 6 inputs and 6 outputs HUMAN MACHINE INTERFACE (HMI) It is a computer based DCS and power automation monitoring system, which has a wide application area and can be used for data acquisition, supervisory and process controls, and it is the most widely used in power systems. With this unit added to the system, the students can perform experiments commonly used in the industrial automation environment. It has a high resolution and includes I/O interfaces such as Serial interface and Ethernet 10/100 base-T. it is available in 7-inch or 10-inch Supervisory Control And Data Acquisition (SCADA) software The system is supplied with Supervisory Control And Data Acquisition (SCADA) software and already installed in the HMI unit. It occupies an important position in remote control systems and can monitor and control on‐site operating equipment to achieve functions such as data acquisition, equipment control, measurement, parameter adjustment, and various signal alarms. It interfaces with the CIM’s PLC. EXPERIMENTS DESCRIPTION Integration of the sensors in CIM experiments: • Capacitive proximity switch • Inductive proximity switch • Photoelectric switch • Electromagnetic sensors On the inspection area (a), the capacitive sensor detects metals, the inductive sensor distinguishes the difference between metals and plastic, and the photoelectric switch detects reflexivity of the object for correct positioning. In the transfer area (b), electromagnetic (reed) sensors collect information regarding strokes of the horizontal rod less cylinder. On the handling area (c), electromagnetic (reed) sensors detect correct positions of the arms during manipulations. Integration and control of dedicated actuators experiments: • DC motor control • Pneumatic cylinders control The DL CIM-C trainer offers an excellent possibility to study, understand, and design the most appropriate applications of a DC motor use (a). Simple, easy to control, with some proper gear, the application for belt conveyer is fast integration of this electric machine in manufacturing chain. The pneumatic actuators, with their elasticity, offer best solutions for alternative linear displacements, and grippers. Together with its electric and pneumatic controlling accessories, and the use of PLC, these execution elements define and describe in an excellent form the mechatronics concept. Through these experiments, the student/user can compare the possibilities of expansion for these actuators, following the main formulated functions for the manufacturing process design. Substation functionality: Linear transfer unit experiment Around a PLC program, that integrates different kind of signals (detection whether has work piece, metal work piece detection, detection whether the work piece coming, START/STOP commands), it is built a linear transportation system, as manufacturing function. Different kinds of working zones are identifiable: process controlling, inspection area, delivering point. Substation functionality: Transfer unit experiment Around a PLC program, that integrates different kind of substation signals (linear transport cylinder stretch out detection, linear transport cylinder retract detection with upstream process signals and type of transported materials), it is built a transfer substation. Through this experiment, we understand the operations sequence and dependencies of the material transportation and handling up to the moment of materials transferring substation. These understood and clarified handling constraints allow expanding solutions for many other classes of transported materials. Substation functionality: Pick and place unit experiment Around another PLC program, that integrates different kind of substation signals (horizontal cylinder stretch out detection, horizontal cylinder retract detection, vertical cylinder stretch out detection, vertical cylinder retract detection) with upstream process signals (related to availability of the materials), it is built this pick and place substation. The implementation and the control of the gripper is the core idea. Through this experiment, we understand the operations sequence and dependencies of the material transportation and handling up to the moment of materials transferring substation. These understood and clarified handling constrains allows expanding solutions for many other classes of transported materials. Six Stations Rotary Table Experiment We study here an integrated motion system (motors, mechanical power transmission devices, encoders, sensors, and controllers). We underline the important parameters for rotary indexing tables (the needed resolution of the application, the required repeatability and accuracy, and other mechanical parameters such as acceptable levels of backlash or hysteresis). Another key parameter is the loading including torque, axial, radial, and moment loads. These can impact the type and size of the indexer used in each application - probably it is the most important element in the production chain (four major interconnected operations: 1- 4). A rotary indexing table can be used in many applications including manufacturing, inspection, and assembly tasks Drilling Module Experiment Hole drilling operation using an elastic driving system (pneumatically operated) offers the possibility to observe, understand, and design later, the main operations: connecting the air source output port of the compressor to the air source input, turning the pressure regulating valve, the drilling control, till the ending operation. It is an application and technique that utilizes high pressure to obtain a mechanical movement. As for many other machine tools used in industrial processes, this station is equipped with standard control (manual or automated, emergency actions). At the same time, we underline some major advantages: safe, robust, powerful, long lasting, easy to maintain. Uploading Arm and Weighing Module Experimen A simple and robust decision maker algorithm has been implemented in DL CIM-C based on the weight of the work pieces. The uploading arm is controlled for selecting pieces of work, in a programmed operations sequence. During the experimenting time, the automation of the uploading process is tested as a concept. Visual Inspection Module Vision inspection systems provide image-based inspection automated for your convenience for a variety of industrial and manufacturing applications. They can measure parts, verifying parts are in the correct position, and recognizing the shape of parts. Computer software processes images captured during the process you are trying to assess to capture data, and they can be embedded into your lines to provide a constant stream of information. The visual inspection module has two work modes: learning mode and compare mode; learning mode is used to update the contrast images stored in the system; the compare mode is that the camera compares the store image with the shoot one, to determine that this image is similar with which picture that pre-existing in the system. These systems can be used in any number of industries in which quality control is necessary. For example, they can assist robotic systems to obtain the positioning of parts to further automate and streamline the manufacturing process. The data collected by a vision system can help improve efficiency in manufacturing lines, sorting, packing and other applications. In addition, the information captured by the vision system can identify problems with the manufacturing line or other function you are examining to improve efficiency, stop inefficient or ineffective processes, and identify unacceptable products. Integration of the substations: CIM experiment The DL CIM-C trainer offers excellent possibility to study, understand, and design the most proper applications where particular substations are implemented to work together. The experiment is mostly focused on sequential execution of different manufacturing operations: 1- reception, loading and first inspection, then transporting materials according with the processes flow, 2- selection point according with inspection algorithms, 3- locating on rotary index for repetitive operations, 4- example of technological process (drilling machine), 5- selection point according with another specific criteria (weight), 6- output selection, palletizing, and preparation for expedition. One time we understand the main operations of defined manufacturing system, the success of using this trainer would be the measure of expansion, or customization according to local requirements. In actual implementation, the PLC sub-programs are working in CIM experiment, like program routines that allow easy understanding of the programming mannerWhat is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review