Industry 4.0 Smart Factory (DL I4.0 FACTORY)

PL-600967

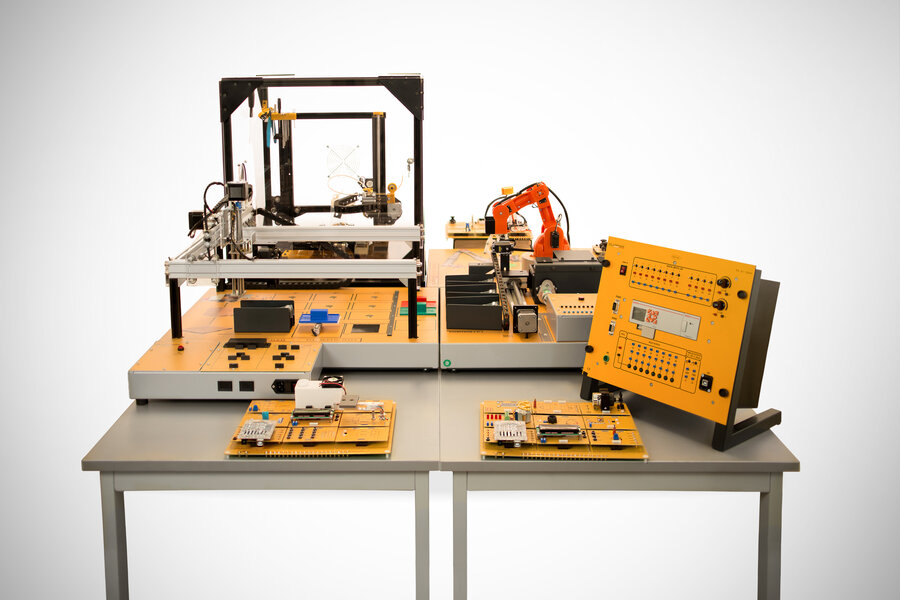

De Lorenzo's solution creates a collaborative environment to study concepts related to Industry 4.0, integrating subsystems typically found in a production plant. The trainer is composed of a set of electronic boards and simulators to study the different subsystems that can be found in a real production line. Using an Arduino open-source microcontroller connected to a SCADA software for data acquisition and control, the students will be able to perform practices covering topics that range from the introduction to automation and robotics, communication protocols (IOT), sensors and actuators to a complete study of a productive system. The trainer is composed of 4 subsystems. Each onecan be studied independently to execute practices covering topics ranging from the operation of sensors and actuators to the introduction of automation and robotics or linked together for the simulation of a more complex Industry 4.0 production line. The student can acquire and analyze the data generated from the interactions between stations to manage and optimize the overall industrial process. CHARACTERISTICS • Multidisciplinary laboratory organized by levels ranging from the most basic concepts of electronics and automation to the simulation of an industrial process. • Hands-on training platform based on experiments. SKILLS DEVELOPMENT • Through an open source platform, students will be able to develop applications using programming and control techniques. • The trainer is a platform to simulate real scenarios. • Development of analytical and problem solving skills. MODULARITY • Collaborative environment to study Industry 4.0 concepts. • Scale model of the systems that make up a factory 4.0. • Modular reconfigurable laboratory. • Platform for project development. OPEN SCADA WEB • Software to monitor and control all subsystems of the trainer. • Learning platform based on a software structured using a didactic approach (CAI). • Open and customizable software. • Remote monitoring and control interface.

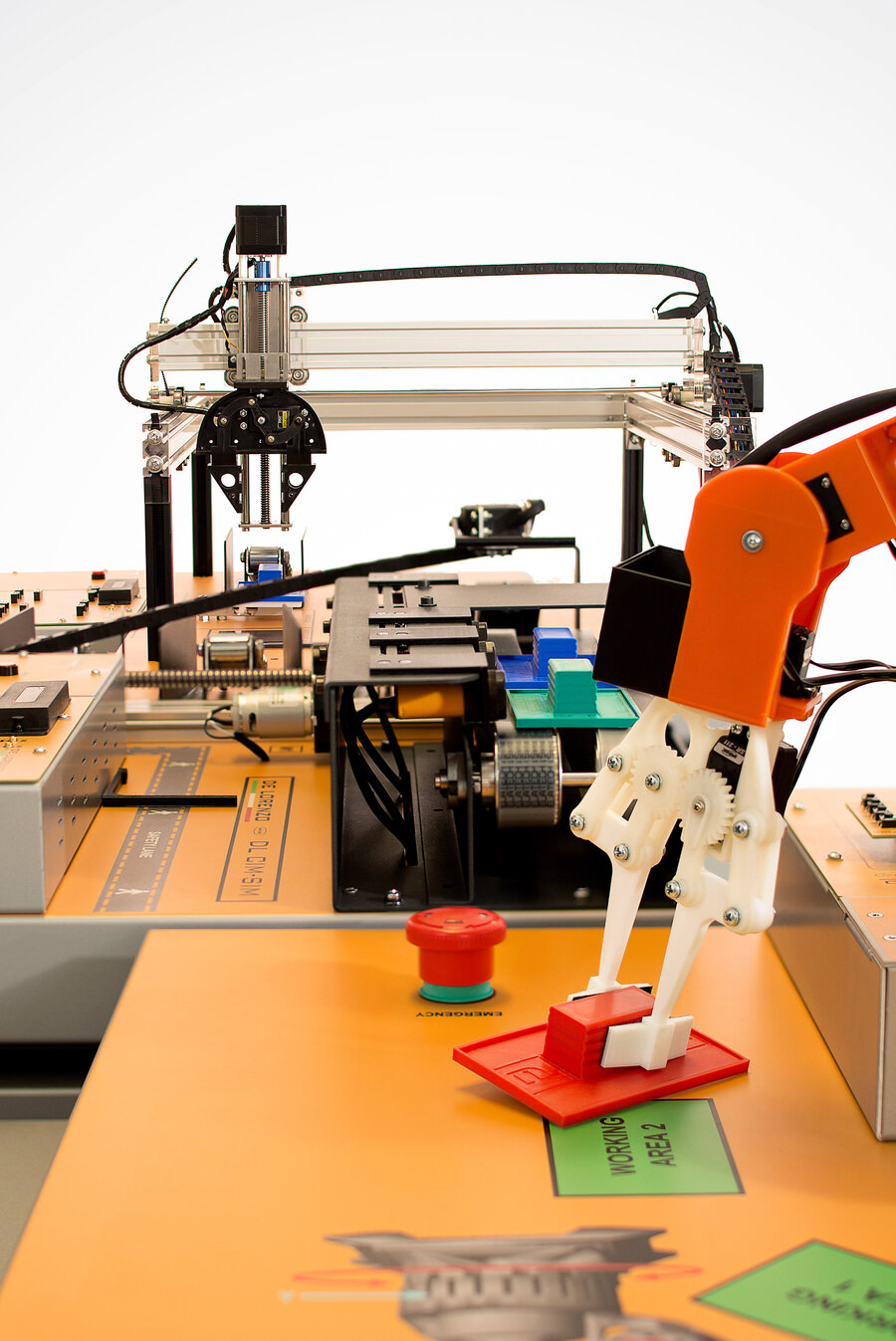

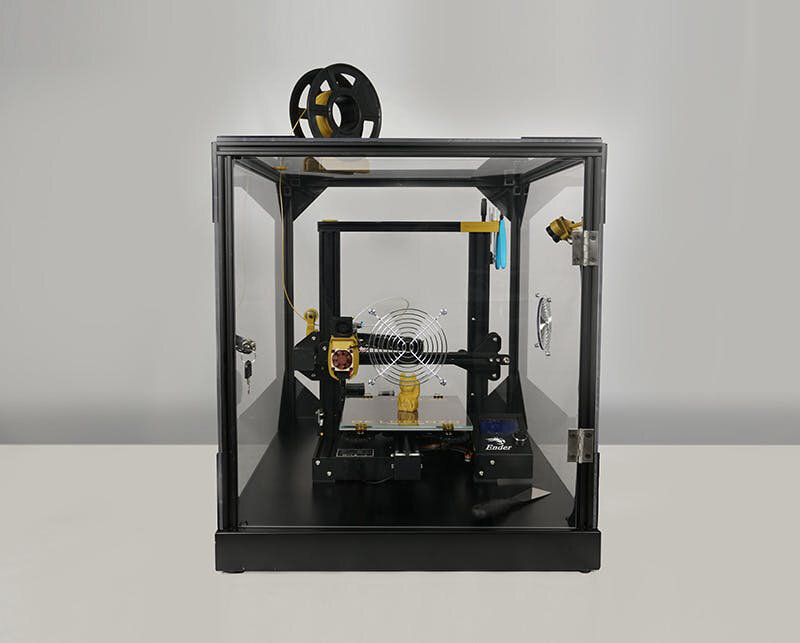

Modulary 1. RFID (RADIO-FREQUENCY IDENTIFICATION): • Use of RFID in industrial environments. • Product traceability 2. 5-AXIS ROBOTIC ARM • Introduction to robotics 3. CONVEYOR BELT: • Introduction to automation • PLC programming 4. SEMI-AUOTOMATIC WAREHOUSE: • Inventory management • Sorting algotithms OPEN SCADA-WEB DL I4.0 FACTORY 1. WITH A DIDACTIC APPROACH: The program is structured with a didactic approach, including the theoretical and practical information necessary to complete the proposed exercises. 2. OPEN CODE: The license allows students to create their own projects and customize them to show the parameters of interest. 3. INTELLIGENT MANAGEMENT: It is possible to generate automatic reports and control actuators for an "intelligent" management of a production process. 4. DISTANCE LEARNING: With the software you can remotely monitor the system from a local or remote PC using an Internet connection. The SCADA software exchanges information with all of the trainer's subsystems, displaying sensor data and system status to monitor the system in real time. The software also acts as a Computer Aided Instruction (CAI) software that guides the student through their learning path. SYSTEM ARCHITECTURE Through industrial SCADA software, all substations are able to exchange and display relevant information. The software is structured to follow a simulated manufacturing process that receives information from the user and generates report files that can be accessed remotely. Processes implemented in the Software include: • Processing a customer order. • Generating a production order • Generating a purchase order • Managing and updating different bills of materials • Monitoring the production process • Managing inventories • Creating packing lists All relevant historical data is recorded on the RFID tag. DIDACTIC APPROACH Level 1: BRS circuit subboards to study individual components (sensors, actuators). Level 2: Integration of the different components in subsystems through an Arduino microcontroller. Level 3: Integration of subsystems with a SCADA system to monitor and control a process. With this trainer, the student will become familiar with the different parts that make up a real industrial process and will learn the corresponding concepts gradually. It will start with the study of the basic hardware up to the practical development of a scale model of the production line. SKILLS DEVELOPMENT 1. TECHNICAL AND VOCATIONAL SCHOOLS • Circuit theory • Programming fundamentals • Sensors and actuators 2. ROBOTICS, TELECOMMUNICATIONS AND ELECTRONICS ENGINEERING COURSES • Study of communication protocols, RFID • Bluetooth, IOT • Automation and control theory • Microcontrollers 3. ENGINEERING STUDIES • Process theory and optimization • Information theory • Industrial automation The DL I4.0 system is composed of the following modules: • DL 3155BRS- RFID: RFID protocol study board. • DL ROB- SIM: Kit for the study of the robotic arm • DL CIM- SIM: Kit for the study of conveyor Belt • DL WMS-SIM: A Kit for the study of warehouse 4.0. KIT FOR STUDY OF RFID APPLICATIONS With this card, students can study the properties of an RFID system and all the components needed to develop a door access control system. Learning experience • Reader behavior when a tag is identified. • How to read data from the proximity IC card using an RFID reader. • How to read and write data blocks on a MIFARE proximity IC card. • How to write personal data to a MIFARE proximity IC card using an RFID reader. • How to read personal data on a MIFARE proximity IC card using an RFID reader. • How to activate a relay using the microcontroller outputs. How to control a display using the microcontroller. • How to control a real-time clock device using the microcontroller. • How to connect a keyboard to a microcontroller. Simulation of a door access control system. DL ROB-SIM; KIT FOR THE STUDY OF THE ROBOT ARM With this card system, students can study the properties of a 5-axis robotic arm used in industrial settings. Sensors and actuators are included to develop a complete course on robot control systems. The system for studying the control systems of a 5- axis robotic arm is composed of two main elements: • A kit of mini board to study the hardware characteristics and control techniques used in a robotic system by means of an open source microcontroller. • A real hardware simulator of a 5-axis robotic arm used in an industrial environment. DESCRIPTION OF THE SYSTEM CIRCUIT BLOCKS Kit composed of mini board for the propaedeutic study of the different elements that compose a robotic arm. LEARNING EXPERIENCES • Characteristics of a joystick controller and interface with the microcontroller. • Study of the ultrasonic proximity sensor, servomotor and its controller. • Introduction to Bluetooth standard and implementation of a Bluetooth interface with the microcontroller. • Flex sensor analysis and its interface with the microcontroller. • Control of an LCD display by means of an I2C communication interface. • Measurement of orientation and angular velocity with a gyroscope. HARDWARE SIMULATOR This system the student will experiment with different methods to control a 5-axis robotic arm and will increase the competence needed for HW design and SW programming of an electromechanical system. LEARNING EXPERIENCES • Study of the robot components. • Control of the arm in real time by means of Joystick. • Step-by-step programming of the movements. • Recording of movements. • Programming of the positioning in the Cartesian plane. • Bluetooth communication. DL CIM- SIM; KIT FOR THE STUDY OF A CONVEYOR BELT With this training system, students can learn about the properties of a conveyor belt used in industrial environments. Sensors and actuators are included to develop a complete course on the main characteristics of conveyor systems and their applications. The trainer for the study of a conveyor belt consists of two main elements: • A kit of mini board to study the hardware features and control techniques of a conveyor belt. • A real hardware simulator of a conveyor belt unit used in a real industrial environment. DESCRIPTION OF THE SYSTEME CIRCUIT BLOCKS Kit composed of mini board for the propaedeutic study of the different elements that compose a conveyor belt system. LEARNING EXPERIENCES • Control of an LCD display through a microcontroller. • Detecting an object by means of an infrared sensor. • Monitoring of an RGB sensor. • Control of a DC motor through a power controller. • Control of a stepper motor. • Acontrol and latching function via a pushbutton panel. Writing on a seven- segment display. HARDWARE SIMULATOR This system is primarily used to teach, demonstrate and experiment with different methods of controlling a conveyor belt. The student will develop the skills for HW design and SW programming of an electromechanical system. LEARNING EXPERIENCE • Control of a conveyor belt through a push button panel. • Use of a PLC to control the movement of the conveyor belt. • Monitoring and identification of a processed part on the conveyor belt. • Tracking the position of a part placed on the conveyor belt. • Identifying and verifying the color of a part. • Identify a defective part and place it in the correct location at the end of the line. DL WMS-SIM; KIT FOR THE STUDY OF A SMART WAREHOUSE With this training system, students can learn about the properties of a semi-automatic warehouse that can be found in industrial environments. The trainer for the study of a warehouse management system is composed of two main elements: • A kit of mini board to study the hardware features and control techniques used in a semi- automatic warehouse. • A real hardware simulator of a semi-automatic warehouse used in a real industrial environment. DESCRIPITON OF THE SYSTEM CIRCUIT BLOCKS Kit composed of mini board for the propaedeutic study of the different elements that make up a semi-automatic warehouse. LEARNING EXPERIENCES • Control of an LCD display through a microcontroller. • Weight measurement with a tension meter. • External temperature and humidity monitoring. • Implementation of a closed-loop ON-OFF controller for a temperature-humidity cycle. • Implementation of a closed-loop PID controller for a temperature-humidity cycle. • Performing measurements with a distance sensor. • Interconnecting a keyboard to a microcontroller. HARDWARE SIMULATOR This system is primarily used to teach, demonstrate and understand the main features and operation of a pick and place system and a semi-automatic warehouse. LEARNING EXPERIENCES • Identifying and weighing an item. • Manually assign an item to an item. • Automatically assign an item to an item. Automatic inventory update. • Manual picking of an item from the warehouse. • Automatic picking of an item from the warehouse. DL FABLAB; MANUFACTURING LABORATORY De Lorenzo proposes the FABLAB, as a fundamental laboratory to help the student move into the future, taking the first steps in the world of 3D modeling. The laboratory, which consists of a high performance 3D printer and a comprehensive didactic manual, aims to guide the student through a complete experience, starting from the mental conception of an object. The complete process proposed by De Lorenzo follows a 4-step cycle: design, modeling, 3D printing and application. With detailed documentation accompanied by practical videos, the student will learn the basics of 3D modeling, mechanics and strength of the models, and will also master the preparation of print files to create objects indispensable in various professional areas. "Accessory Sold separately" SCADA SOFTWARE FOR INDUSTRY 4.0 CHARACTERISTICS The Industry 4.0 training system is controlled by industrial SCADA (Supervisory Control and Data Acquisition) software that exchanges information with all subsystems of the trainer, displaying sensor data and system status for real-time control. The software learning platform (CAI) is structured using a didactic approach, including the theoretical and practical information necessary to address the proposed topics. PRACTICES Through the monitoring system, all substations that make up the Industry 4.0 trainer are able to exchange data and display process-relevant information. • Processing a customer order. • Generate a production order. • Generate a purchase order. • Manage and maintain different bills of materials. • Supervise the production process. • Manage inventories. • Create packing lists.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review