Refrigeration And Air Conditioning Training System (DL TMAC11)

PL-100747

Refrigeration and air conditioning training developed to demonstrate the operation and working principle of a cooling system. Students will be able to follow the refrigeration cycle, explore the layout and functions of all main components and perform maintenance and troubleshooting exercises. The didactic system is fully operable and contains all the basic components of refrigeration and air conditioning system. The components are exposed and mounted on a vertical frame. The students control and monitor the experiments procedure using instruments and transparent observation points.

MAIN CHARACTERISTICS

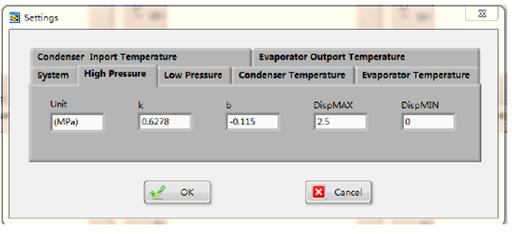

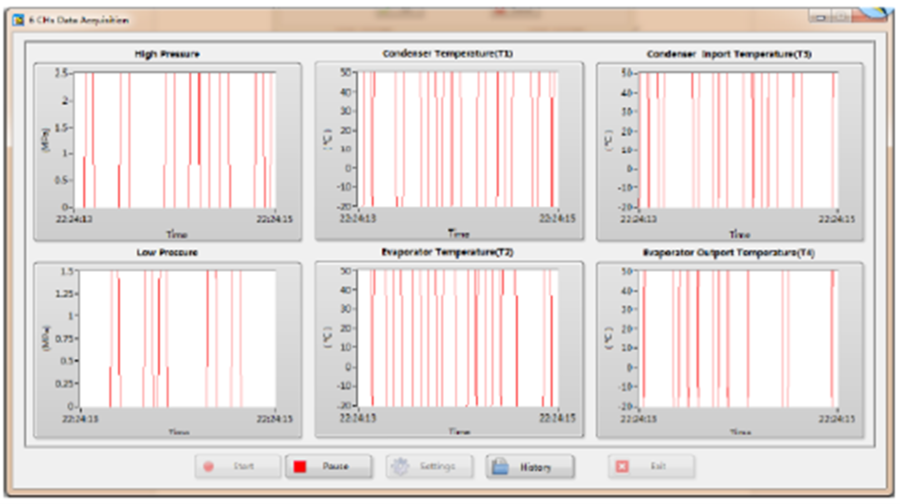

• The trainer combines air conditioning system, refrigerating system and electronical control system. • The trainer is based on a real domestic heat pump type air conditioner and a real domestic refrigerator • The air conditioner can be controlled by remote controller. • Working temperatures, pressures and electrical values can be directly read from meters for working principle understanding. • It clearly the refrigerator inner components layout and refrigerating cycle system structure; It demonstrates the operating principle of the refrigerator and a heat pump type air conditioner; in includes schematic diagram of control system and relative test points; sight glass in the pipeline is used to observe refrigerant status; HV pipeline is marked with red, while LV pipeline with blue, relative components are all labelled. • It includes a connection area for electrical control circuit of outdoor unit for students’ hands-on ability training. • It includes fault introduction systemAir conditioning system • Main components: compressor, high pressure gauge, low pressure gauge, four-way valve, condenser, evaporator, sight glass, filter, capillary, sensors etc. • Electronical control system is composed of o Timer indicate light,power indicate light, compressor indicate light, remote receiver, auto button, compressor working status light,outdoor fan status light,four-way status light, indoor fan motor high speed running light, indoor fan motor middle speed running light, indoor fan motor low speed running light. o 6 relay testing points, 2 NTC test point, test points for DC 12V and DC 5V Refrigerator system • Main components: compressor, high pressure gauge, low pressure gauge, condenser, evaporator, capillary, sight class, refrigerator room simulating cabinet, temperature adjusting nob, 2-position 3-way solenoid valve, sensors, control valve; • Electronical control system is composed of o Compressor status light, deep freezing light, deep freezing button, start button, stop button, temperature adjust nob; o 2 test points for relays, 2 NTC test points, test points for DC 12V and DC 5V • Main electrical control part • Power supply: AC voltmeter, AC ammeter, fuse, mains with leakage protection, pilot LED, switch with key 1pc,emergency stop button 1pc • Four temperature meters • Test points • Connection area • Terminals for electronical connection to accomplish the cooling control functions. Faults can be simulated manually here. • Power supply: 220V 50Hz • Size: 1200 mm *800mm *1910mm(L*W*H) • Weight: 70kg EXPERIENCIA DIDÁCTICA DIDACTIC EXPERENCE With this trainer is possible follow the experiments below: Air conditioning • Electrical connection • Cooling experiment • Heating Experiment • Ventilating experiment • Dehumidifying Experiment • Fault simulation of outdoor fan motor • Fault simulation of compressor • Fault simulation of four-way valve • Fault simulation of indoor fan motor at various speed • Filth blockage simulation of air conditioner refrigeration system • AUTO KEY mode of air conditioner • Refrigerant recycling of air conditioning system • Refrigerant filling of air conditioning system Experiments of refrigerator • Electrical connection • Deep freezing experiment • Fault of compressor • Fault of solenoid valve 2 • Fault of solenoid valve 1 • Fault of Filth blockage Practicing Experiments • Pressure maintaining and leak detection of refrigeration system • Pipe cutter training • Copper pipe flaring training • Pipe bender training The system is supplied with data acquisition software

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review