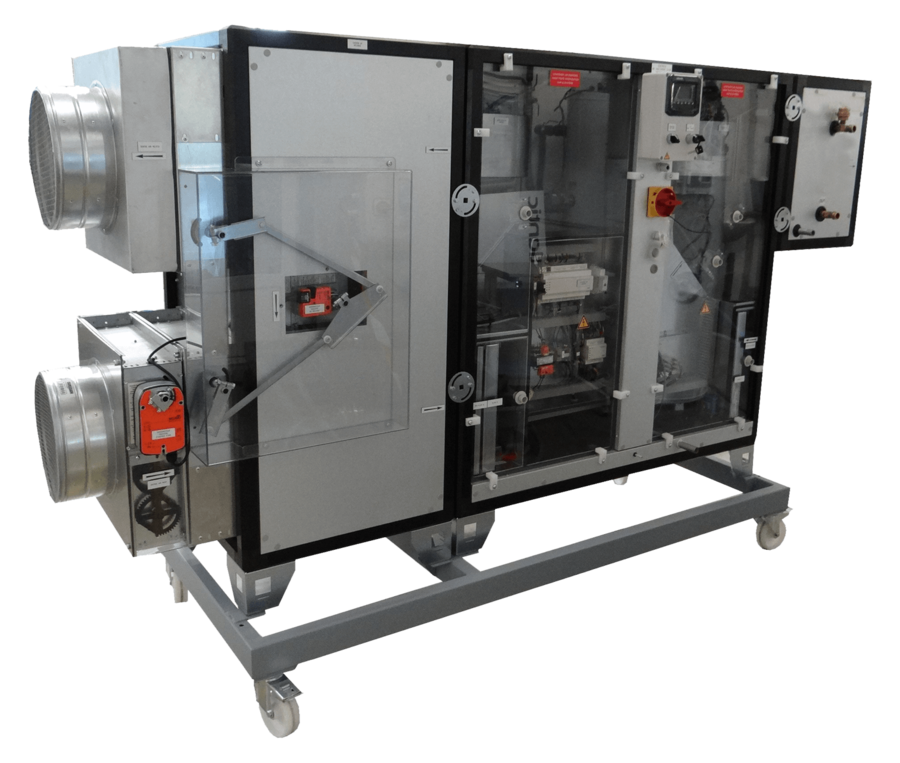

CTA Compact (CC00)

PL-657339

This Air handling system with energy recovery, recycling, heating, cooling, humidifying and industrial supervision, is an excellent didactic tool to teach students in a hands-on manner about comissioning and maintenance of a instrumented compact air handling system.

Features:

- Blowing and extraction

- Mixing and heat recovery(plate heat exchanger)

- Filtration(medium, high efficiency)

- Heating(hot water or electric coil)

- Cooling(cold water coil)

- Heat recovery(plate heat exchanger)

- Steam humidification

- Sensors (temperature, pressure, hygrometry...)

- Centralized Energy Management system (CEM)

Training activities:

- Analyzing the functions of a air-handling system

- Study of PLC and communication network in a building (CEM)

- Commissioning& Configuration

- Climatic and electrical maintenance

- Analysis of the refrigeration, electrical and air flow circuits

- Energy balance and calculation of the performance ratios

- Forecasting the operating conditions

Key points:

- Professional equipment used in collective buildings

- Customized measurements

- Easy-to-use and friendly supervision software

- Open system to main communication protocols (Ethernet, LonWorks, BACNet, Modbus, KNX)

References:

- CC00: High performance Double flow air handling system with: Exchanger 90%, CC motors with low consumption electronical commutation (Flow up to 1000m3/h), Filtration G4+F7 on blowing and filtration G4 on return, Bypass, Power box with communication capable PLC and temperature & pressure sensors, Control and configuration box, configuration and supervision software on Modbus local network

- CC15: Flexible connection (6m.long, diam.315mm), from the Air handling unit to an external wall

- CC10: Electric coil for pre-heating 3.6kW and post-heating 6kW

- CC11: Water coil for post-heating or cooling

- CC12: Mixing case with anti freeze register and one-way motorized shutters

- CC13: Steam humidification case

- PC30: Air/Water reversible inverter 10kW chiller

- CC01: CO2, hygrometry and presence sensors for advanced control

- CC02: KNX gateway (supervision application not provided)

- CC04: Modbus TCP/IP Module on PLC

- CC05: BAC NET IP Module on PLC

- WM01/WM02: Measuring instruments (see CTA Flex references)

Technical Specifications:

- Blowing and extraction (EC motor drive fan)

- Mixing and heat recovery (plate heat exchanger)

- Filtration (medium, high or very high efficiency)

- Heating (hot water or electric coil)

- Cooling (cold water coil)

- Steam humidification

- Sensors (temperature, pressure, hygrometry...)

- Schneider Centralized Energy Management (CEM) system

- Open system to main communication protocols (Ethernet, LonWorks, BACNet, Modbus, KNX)

- CO2, hygrometry and presence sensors for advanced control

Blowing and extraction (EC motor drive fan)

Mixing and heat recovery (plate heat exchanger)

Filtration (medium, high or very high efficiency)

Heating (hot water or electric coil)

Cooling (cold water coil)

Steam humidification

Sensors (temperature, pressure, hygrometry...)

Schneider Centralized Energy Management (CEM) system

Open system to main communication protocols (Ethernet, LonWorks, BACNet, Modbus, KNX)

CO2, hygrometry and presence sensors for advanced control

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review