Comprehensive Testing and Diagnosis Unit for Hybrid Engine with Braking and Diagnostic Software (TBM/H)

PL-819555

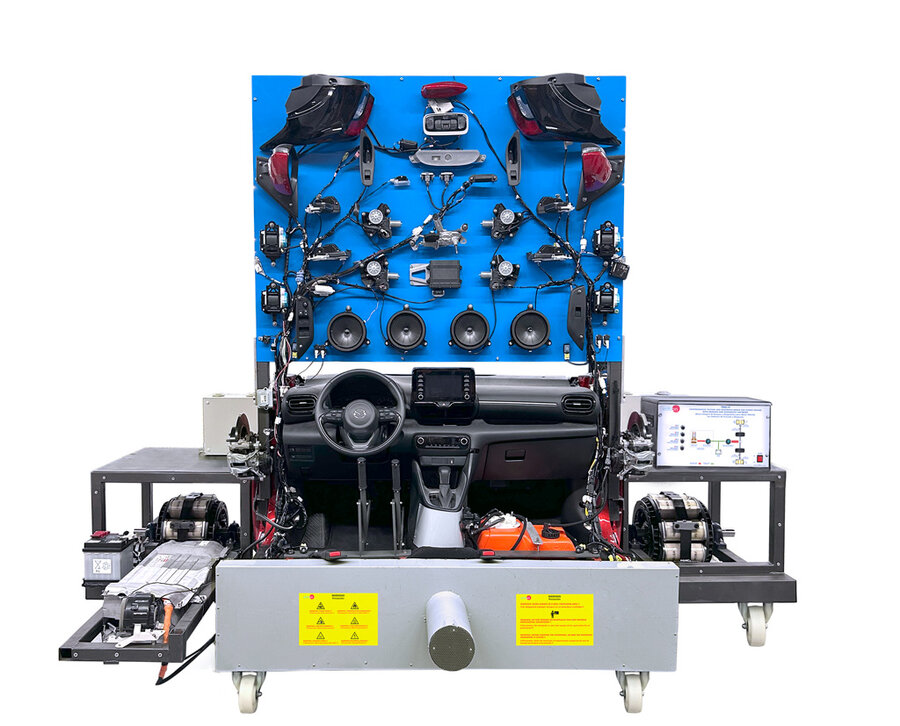

The Advanced Hybrid Engine Testing and Diagnostic Unit with Braking System and Software, “TBM/H”, developed by EDIBON, is a cutting-edge solution for the analysis of hybrid engine performance. Designed to support education in automotive engineering and sustainable mobility, this unit enables performance testing, component evaluation, and fault diagnosis—contributing to improved efficiency and deeper understanding of hybrid propulsion systems.

The system is organized into three primary sections, each dedicated to analyzing and understanding the various subsystems of a hybrid vehicle under real-world operating conditions:

- Central Control Panel and Cabin Systems: Positioned at the center of the unit, the blue control panel contains key electronic components typically found in a vehicle's cabin. These include systems like power windows, interior lighting, seat belts, door locks, and windshield wipers. This configuration allows users to study the integration and operation of automotive electronics that contribute to comfort, safety, and functionality.

- Driver and Co-Driver Area: Located beneath the central panel, this section includes critical driving controls such as the steering wheel, accelerator, brake pedals, gear shifter, and instrument cluster. It also features a built-in diagnostic system that connects to a computer for real-time parameter monitoring and fault detection, enabling detailed operational analysis. Additional components include the glove compartment and fuel tank on the right side, and parking brakes on both sides of the section—offering a realistic replication of an actual vehicle cockpit.

- Hybrid Powertrain and Braking Simulation System: Positioned to the left of the central panel is the battery block, which includes a 12V battery for powering the internal combustion engine and a hybrid battery for driving the electric motor during specific operation modes. To prevent thermal stress, a cooling fan is automatically triggered when battery temperature surpasses a defined threshold. On each side of the unit, an eddy current braking system simulates changes in vehicle load, creating resistance against wheel rotation to replicate different driving conditions. This resistance is fully adjustable via an intuitive interface on the right-hand panel, allowing users to test variables such as torque, wheel speed, acceleration, and engine power.

Brakes are connected to load cells, enabling real-time measurement of engine torque, while speed sensors located on the steering axle deliver accurate data on vehicle speed. This high-precision instrumentation enables detailed analysis of power delivery and hybrid system performance under various simulated driving scenarios.

The overall design of the TBM/H facilitates comprehensive testing in multiple conditions, allowing educators and students to explore hybrid engine behavior and efficiency in a controlled setting. Thanks to its advanced simulation features and diagnostic tools, the TBM/H is an indispensable platform for training in automotive engineering, hybrid systems, and sustainable vehicle technologies. It provides users with hands-on experience in the operation, diagnostics, and optimization of hybrid propulsion systems.

- TBM/H. Unit:

- Anodized aluminum frame and panels made of painted steel.

- The unit includes wheels to facilitate its mobility.

- Central control panel, housing the main electrical systems of the cabin: power windows, interior lighting, door locking systems, seat belts with activation sensors, windshield wiper system.

- Driver and passenger area, with steering wheel, accelerator and brake pedals, gear shift, instrument panel, diagnostic system, and fuel tank.

- Internal combustion engine with an electronic injection system and an electric motor assisted by a high-voltage hybrid battery.

- Battery block, composed of:

- 12V battery, supplying power to the combustion engine.

- Hybrid battery, responsible for powering the electric motor.

- Original vehicle fuel tank.

- Cooling system, with an automatic cooling fan that activates when the battery temperature exceeds a predefined threshold.

- Diagnostic interface for monitoring and analyzing fuel consumption, performance, and fault detection.

- Eddy current brakes.

- Sensors and measurement systems with load cells and speed sensors on the steering axle.

- Protected systems for fully safe operation

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with manuals.Required services, Assembly and Installation, Commissioning, Safety, Maintenance, and Practices manual.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Familiarization with a hybrid driving system.

- Determination of fuel consumption (combustion engine) and voltage and current demand of the battery (electric motor).

- Study of torque and power curves versus engine revolutions for the hybrid system.

- Measurement of key process parameters: torque, speed, power, acceleration, etc.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review