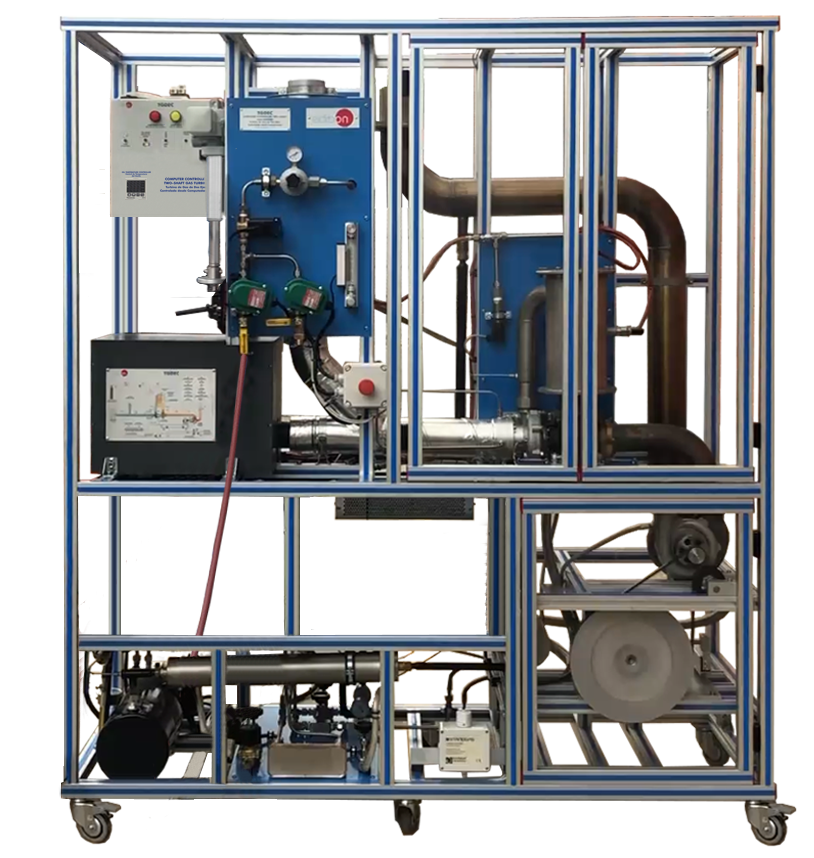

Computer Controlled Two-Shaft Gas Turbine - Jet Engine (TGDEPC)

PL-892626

Key features:

- Advanced Real-Time SCADA.

- Open Control + Multicontrol + Real-Time Control.

- Specialized EDIBON Control Software based on LabVIEW.

- National Instruments Data Acquisition board (250 KS/s, kilo samples per second).

- Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

- Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

- Capable of doing applied research, real industrial simulation, training courses, etc.

- Remote operation and control by the user and remote control for EDIBON technical support, are always included.

- Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic & Software).

- Designed and manufactured under several quality standards.

- Optional ICAI software to create, edit and carry out practical exercises, tests, exams, calculations, etc. Apart from monitoring user's knowledge and progress reached.

- This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

The Computer Controlled Two-Shaft Gas Turbine/Jet Engine, “TGDEPC”, developed by EDIBON, is a teaching unit for the operation demonstration of a Double Shaft Gas Turbine for electric generation and for other uses too. Moreover, the unit can be configured as a Jet Engine. A Gas Turbine is an internal combustion rotating motor. Its name is due to its working fluid being a gas, generally air. Basically, it consists of a compressor, where the inlet air pressure is increased and goes to a combustion chamber where a thermal energy input is carried out, and a turbine, where the hot gas expands. The turbine and the compressor are placed on the same axis, so a part of the energy generated in the turbine is used by the compressor to compress the air. The importance of studying the gas turbine is given by its great field of application, among its uses we can mention: Gas turbine for electricity generation. Combined cycle together with vapour turbine. Cogeneration: It is a combined cycle of electric power and thermal power. Reactor: in aviation field applications. The gas turbine as jet engine. Turboprops: unlike the turbojet the turbine is designed to obtain the maximum mechanic energy possible, which is used to move a propeller.

The main element of the Computer Controlled Two-Shaft Gas Turbine/ Jet Engine, “TGDEPC”, is the High Pressure Turbine, which is also called Gas Generative Turbine. It consists of: - Radial compressor, which is feeded by atmospheric air to compress it. - Tubular combustion chamber. In every combustion there is a fuel (propane gas); a comburent, which in this case is compressed air received from the compressor, and the activation energy which will cause the ignition of the mix. - Expansion turbine: The inflamed gases of the combustion chamber transfer a part of the thermal energy that they have in the turbine blades. Compressor and turbine are mounted on the same shaft, so, when we have the system self sustaining, part of the thermal energy of the combustion gases is used to move the compressor. The extra thermal energy of the combustion gases is driven to the Low Pressure Turbine, or also called Power Turbine. In it, the rest of the combustion gases energy is transformed in mechanic energy, which is transformed in electric energy through a generator coupled to the turbine shaft. The second possibility of the “TGDEPC” unit operation is as a single shaft jet engine. The nozzle accessory is assembled to the Generative Turbine, what will cause an exhaust gases acceleration with the consequential reaction, which will be measured by a force sensor (load cell). The TGDEPC unit also includes: Start system: It consists of a centrifugal fan driven by an electrical motor. Air provided by this fan acts on the blades of the compressor, causing the rotation of the high pressure turbine. Fuel system: The line of fuel gas consists of a ball valve to open or close the feeding, a pressure regulation valve, a safety solenoid valve and an injector. It includes a flow sensor to measure de gas consumption. Ignition system: The activation energy of the air-fuel mix will cause the flame ignition. It consists of an ignition electrode or spark plug feeded by an ignition transformer. An ionization electrode detects that the flame is ignited. Lubrication system: It consists of an oil tank of 5 l. From this tank, we dispose of a gear pump to impulse the oil to the bearings of both turbine shafts. The system is completed with a filtration unit and two regulation valves to select the oil quantity to feed to each turbine. Refrigeration system: It consists of a plate heat exchanger and a tubular heat exchanger through which the oil transfers its heat to the refrigeration water. This Computer Controlled Unit is supplied with the EDIBON Computer Control System (SCADA), and includes: The unit itself + a Control Interface Box + a Data Acquisition Board +Computer Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Study of a gas turbine operation.

- Determination of the gas turbine efficiency.

- Determination of the compressor operation point.

- Study of a gas turbine operation as a jet engine.

- Operation with power turbine.

- Determination of fuel consumption.

- Thermal efficiency.

- Air standard cycle.

- Heat balance.

- Work ratio.

- Pressure ratio.

- Pressure loss.

- Air and fuel ratio.

- Combustion efficiency.

- Recording the turbine characteristic curve.

- Determination of the efficiency of the compressor.

- Determination of the efficiency of high pressure turbine.

- Determination of the efficiency of output turbine (low pressure).

- Temperatures measurements.

- Effective turbine output power.

- Safety systems in the operation of a gas turbine.

- Thrust measurement.

- Sensors calibration.

- Many students view results simultaneously. To view all results in real time in the classroom by means of a projector or an electronic whiteboard.

- Open Control, Multicontrol and Real Time Control. This unit allows intrinsically and/or extrinsically to change the span, gains; proportional, integral, derivative parameters; etc, in real time.

- The Computer Control System with SCADA allows a real industrial simulation.

- This unit is totally safe as uses mechanical, electrical/electronic, and software safety devices.

- This unit can be used for doing applied research.

- This unit can be used for giving training courses to Industries even to other Technical Education Institutions. 30.-Control of the TGDEPC unit process through the control interface box without the computer. 31.-Visualization of all the sensors values used in the TGDEPC unit process.

- Several other exercises can be done and designed by the user

TGDEPC. Unit: Anodized aluminum frame and panels made of painted steel. The unit includes wheels to facilitate its mobility. Main metallic elements made of stainless steel. Diagram in the front panel with distribution of the elements similar to the real one. Using this unit the operation of both a two shaft gas turbine system for electric generation and a jet engine can be study and investigate. High Pressure Turbine, that it is the Gas Generative Turbine. It consists of: Radial compressor. Tubular type combustion chamber. Expansion turbine. Operation speed range: 70000 – 90000 rpm. Max. compression ratio: 2:1. Max. fuel consumption: 20 kg/hour. Low Pressure Turbine (Power Turbine): Speed range (r. p. M.): 15000 – 25000 rpm. Electrical power: Measurement range: 0 – 500 W. Asynchronous (motor) generator; computer controlled; speed range: 1500 – 3000 rpm. Power: 1.5 kW. Power turbine connection and generator by means of adjustable belt drive. Operation as a jet engine: Turbine speed range: 60000 – 160000 rpm. Trust nozzle, with force sensor (load cell). Trust measuring range: 0 – 50 N. Start fan, driven by an electrical motor, for starting the turbine and gas sweep. This fan is automatically computer controlled and it is used to refrigerate. Aspiration muffler. Line of fuel gas, consists of: Valve to open or to close the feeding. Pressure regulation valve. Flow sensor, range: 12 - 80 l/min. Solenoid valve, automatically computer controlled. Gas injector. Computer controlled proportional solenoid valve to control fuel flow. Spark plug, automatically computer controlled, powered by an ignition transformer. Ionization electrode, automatically computer controlled, to detect that the flame is ignited, as security system. Lubrication system, consists of: Oil tank of 5 l. Gear pump, automatically computer controlled, to impulse the oil to the bearings of both turbine shafts. Filtration unit. Two valves for regulating the oil feed to the turbine. Plate heat exchanger to cool the oil leaving the turbines. Tubular heat exchanger to cool the oil entering the turbines. Water supply connections. Exhaust gas outlet and exhaust muffler. Adjustable electrical resistance (Resistance 1000 W, 40 Ohm) as a charging element.

Sensors and instrumentation: Eight temperature sensors, “K” type, placed in the different process stages (temperature range: 0 – 1100 °C): Temperature of the inlet air to the compressor. Temperature of the inlet air to the combustion chamber. Temperature of the inlet gases to the gas generative turbine. Temperature of the inlet gases to power turbine. Temperature of the exhaust gases. Temperature of the bearing lubrication oil. Temperature of the inlet refrigeration water. Temperature of the outlet refrigeration water. Two speed sensors to measure the rpm of each turbine, measurement range: 0 – 200000 rpm. Five pressure sensors, for measuring: Fuel (propane gas) pressure at the combustion chamber inlet, range: 0 – 2 bar. Pressure in the combustion chamber, range: 0 – 2 bar. Pressure at the turbine outlet, range: 0 – 2 bar. Compressor outlet, range: 0 – 2 bar. Compressor inlet, range: 0 – 100 mbar. Three flow sensors: Inlet air, range: 0 – 3000 m³/h. Outlet gases, range: 0 – 3000 m³/h. Fuel gas, range: 12 - 80 l/min. Force sensor (load cell) of the generator. Force sensor (load cell), thrust measuring: 0 – 50 N. Four manometers, range: 0 – 2 bar. Three pressure switches to control air and oil circuits. ATEX flowmeter for measuring the gas consumption at any moment. Current and voltage measurement. Handling box with PLC, which includes: Front panel with LEDs indicating the unit status. Oil temperature control display. Safety system to prevent faults. Operation with propane. The complete unit includes as well:

Advanced Real-Time SCADA. Open Control + Multicontrol + Real-Time Control. Specialized EDIBON Control Software based on LabVIEW. National Instruments Data Acquisition board (250 KS/s, kilo samples per second). Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements. Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time. Capable of doing applied research, real industrial simulation, training courses, etc. Remote operation and control by the user and remote control for EDIBON technical support, are always included. Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic & Software). Designed and manufactured under several quality standards. Optional ICAI software to create, edit and carry out practical exercises, tests, exams, calculations, etc. Apart from monitoring user's knowledge and progress reached. This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

TGDEPC/CIB. Control Interface Box: The Control Interface Box is part of the SCADA system. Control interface box with process diagram in the front panel and with the same distribution that the different elements located in the unit, for an easy understanding by the student. All sensors, with their respective signals, are properly manipulated from -10V. to +10V. computer output. Sensors connectors in the interface have different pines numbers (from 2 to 16), to avoid connection errors. Single cable between the control interface box and computer. The unit control elements are permanently computer controlled, without necessity of changes or connections during the whole process test procedure. Simultaneous visualization in the computer of all parameters involved in the process. Calibration of all sensors involved in the process. Real time curves representation about system responses. Storage of all the process data and results in a file. Graphic representation, in real time, of all the process/system responses. All the actuators’ values can be changed at any time from the keyboard allowing the analysis about curves and responses of the whole process. All the actuators and sensors values and their responses are displayed on only one screen in the computer. Shield and filtered signals to avoid external interferences. Real time computer control with flexibility of modifications from the computer keyboard of the parameters, at any moment during the process. Real time computer control for pumps, compressors, heating elements, control valves, etc. Real time computer control for parameters involved in the process simultaneously. Open control allowing modifications, at any moment and in real time, of parameters involved in the process simultaneously. Three safety levels, one mechanical in the unit, another electronic in the control interface and the third one in the control software.

DAB. Data Acquisition Board: The Data Acquisition board is part of the SCADA system. PCI Express Data acquisition board (National Instruments) to be placed in a computer slot. Bus PCI Express. Analog input: Number of channels= 16 single-ended or 8 differential. Resolution=16 bits, 1 in 65536. Sampling rate up to: 250 KS/s (kilo samples per second). Input range (V)=±10 V. Data transfers=DMA, interrupts, programmed I/0. DMA channels=6. Analog output: Number of channels=2. Resolution=16 bits, 1 in 65536. Maximum output rate up to: 900 KS/s. Output range (V)=±10 V. Data transfers=DMA, interrupts, programmed I/0. Digital Input/Output: Number of channels=24 inputs/outputs. D0 or DI Sample Clock frequency: 0 to 100 MHz. Timing: Number of Counter/timers=4. Resolution: Counter/timers: 32 bits. The Data Acquisition board model may change at any moment, providing the same or better features than those required for the unit.

TGDEPC/CCSOF. Computer Control + Data Acquisition + Data Management Software: The three softwares are part of the SCADA system. Compatible with actual Windows operating systems. Graphic and intuitive simulation of the process in screen. Compatible with the industry standards. Registration and visualization of all process variables in an automatic and simultaneous way. Flexible, open and multicontrol software, developed with actual windows graphic systems, acting simultaneously on all process parameters. Management, processing, comparison and storage of data. Sampling velocity up to 250 KS/s (kilo samples per second). Calibration system for the sensors involved in the process. It allows the registration of the alarms state and the graphic representation in real time. Comparative analysis of the obtained data, after the process and modification of the conditions during the process. Open software, allowing the teacher to modify texts, instructions. Teacher’s and student’s passwords to facilitate the teacher’s control on the student, and allowing the access to different work levels. This unit allows the 30 students of the classroom to visualize simultaneously all the results and the manipulation of the unit, during the process, by using a projector or an electronic whiteboard.

Cables and Accessories, for normal operation. Manuals: This unit is supplied with 8 manuals: Required Services, Assembly and Installation, Interface and Control Software, Starting-up, Safety, Maintenance, Calibration & Practices Manuals. References 1 to 6 are the main items: TGDEPC + TGDEPC/CIB + DAB + TGDEPC/CCSOF + Cables and Accessories + Manuals are included in the minimum supply for enabling normal and full operation.

REQUIRED SERVICES

- Electrical supply: single-phase 200 VAC – 240 VAC/50 Hz or 110 VAC – 127 VAC/60 Hz. - Water supply (min. 3 l/min.) and drain. - Exhaust gases extractor. - Computer.

REQUIRED CONSUMABLES (Not included)

- Propane 1.5 – 2.5 bar.

DIMENSIONS AND WEIGHTS

TGDEPC: Unit: -Dimensions: 2000 x 700 x 1900 mm approx. (78.73 x 27.55 x 74.80 inches approx.) -Weight: 150 Kg approx. (330 pounds approx.). Control Interface Box: -Dimensions: 490 x 330 x 310 mm approx. (19.29 x 12.99 x 12.20 inches approx.) -Weight: 10 kg approx. (22 pounds approx

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review