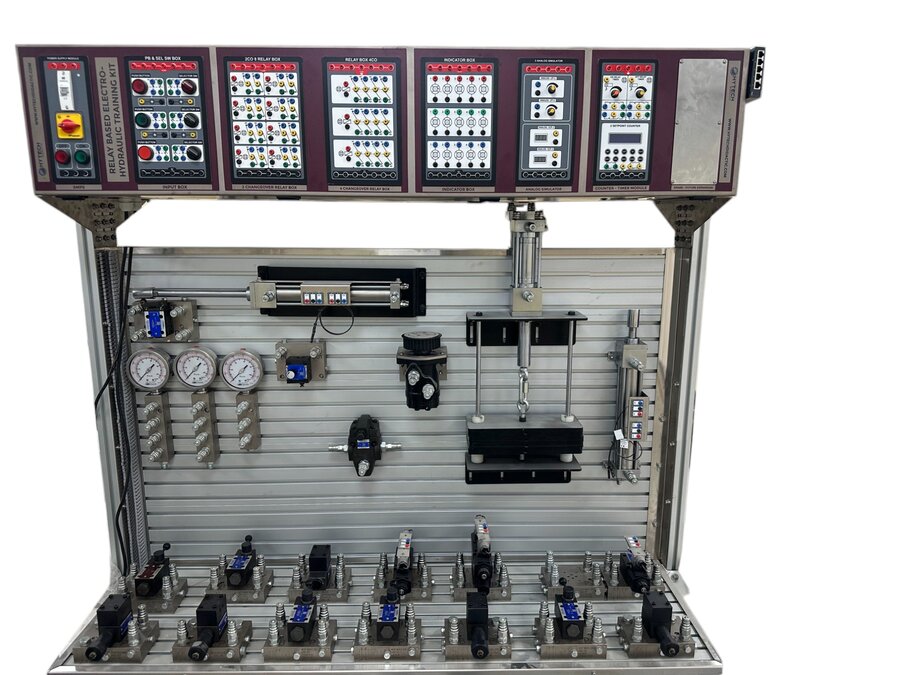

Electrohydraulic Training Kit - Advanced (ELHT-Advance)

PL-720759

Advance Electrohydraulic Training Kit with PLC Hytech Hydraulic Training kits are designed to provide complete training on Hydraulics where participants start from novice and are expected to reach the expert level with two available options (Basic and Advance).

Basic Hydraulic Training Kit is designed to provide hands on experience on conventional hydraulic valves. Most of the commonly used hydraulic valves are provided along with Basic Hydraulic Training Kit.

Students are expected to design and simulate the basic Hydraulic circuits on Simulation software and execute the same on basic Hydraulic training kit. Safety comes first in Hytech training kits.

There are two pressure relief valves provided with each Hytech Hydraulic training kit. PRV mounted on the hydraulic power pack is lockable while the one on the experiment table is used for experimentation purpose. Electrohydraulic training kit is provided with advanced level conventional valves, solenoid valves, pressure switch as well as the PLC.

Participants are expected to operate advanced hydraulic valves in collaboration with PLC. All necessary accessories such as input and output modules are provided to make it easily operable for participants. Automation modules can be connected with Basic as well as Advance training kits which give participants necessary hands on experience on industrial hydraulic applications where participants can relate the use of various hydraulic valves.

‘Hytech’ Hydraulic training kit is designed for educational purpose where students can easily operate the training kits to get necessary hands on experience. Safety is of utmost importance when it comes to operation by students and we have focused on the same aspect in both models of our hydraulic training kits.

Hydraulic training kit (Model: Advance) is a level above Basic Hydraulic training kit.

Before operation Advance training kit, participants are expected to have knowledge about Basic Hydraulics. Advance Hydraulic training kits consists of almost all hydraulic valves which are provided in Basic Hydraulic Training kit. In this training kit, participants are expected to design complex hydraulic circuits on IRAI Automgen software and execute them on the hardware kit.

Industrial starter (MPCB) with variable overload protection for hydraulic powerpack Remote input switches for PLC start signal Sub plate mounted (CETOP 3) valves for better understanding Hard piped connections up to Pressure and Tank manifolds on each side of double faced Aluminum profile based training kit Basic Valves on back face of the training kit and advance valves on front side of the training kit. At a time, 6 students can work on the training kit PLC operated training kit with PLC and Field input – output modules Online circuit design and simulation software with online PLC ladder updation.

Computer controlled training kit. Mobile hose trolley Workstation with Licensed PLC ladder design software Indigenously designed hydraulic valve plates with parallel A and B ports for dynamic pressure monitoring Provision to connect proportional valve training kit with PLC and HMI as well as workstation integration

Details of Hydraulic Training Kit Modules: Sr No Description Qty Make 1 Trainer Kit Base and Structure (Basic) Basic Hydraulic Trainer Base with Aluminum extrusion based work surface (Double Sided) of minimum dimensions: Horizontal work area on front face : 1200mm x 360mm Horizontal work area on back face : 1200mm x 360mm Vertical work area on front face : 1200mm x 720mm Vertical work area on back face : 1200mm x 720mm MS based structure with castor wheels and load bearing capacity of 380 KG Drip Tray: 1200mm x 800mm 1 HYTECH 2 Trainer Kit Base and Structure (Advance) Advance Hydraulic Trainer Base with Aluminum extrusion based work surface (Double Sided) of minimum dimensions: Horizontal work area on front face : 1200mm x 450mm Horizontal work area on back face : 1200mm x 450mm Vertical work area on front face : 1200mm x 720mm Vertical work area on back face : 1200mm x 720mm MS based structure with castor wheels and load bearing capacity of 380 KG Drip Tray: 1200mm x 850mm 1 HYTECH 3 Trainer Kit Base and Structure (Proportional Kit) Proportional Hydraulic Trainer Base with Aluminum extrusion based work surface of minimum dimensions: Horizontal work area : 1200mm x 720mm MS based structure with castor wheels and load bearing capacity of 380 KG 1 HYTECH 4 Hydraulic Power Pack Module 4.1 Hydraulic tank with 60 Litre capacity, Oil cleanliness: Level 8 1 HYTECH 4.2 Three Phase flange mounted electric motor 2 HP -1500 rpm 1 Siemens / CG 4.3 Gear Pump (Flow Rate: 8 LPM, Max Pressure: 70 Bar) 1 Yuken / Rexroth 4.4 Pressure Gauge 0 to 100 Bar, Glycerin filled, 2 inch 2 Baumer / WIKA 4.5 Pressure Relief Valve (Subplate Mounted) with Locking Arrangement 1 Yuken / Rexroth 4.6 Suction Line Filter 1 Reputed Make 4.7 Return Line Filter 1 Reputed Make 4.8 Pressure Line Manifold with 4 Ports (Hard piped with powerpack and mounted on the front work surface) 1 HYTECH 4.9 Pressure Line Manifold with 2 Ports (Hard piped with powerpack and mounted on the rear work surface) 1 HYTECH 4.10 Return Line Manifold with 4 Ports (Hard piped with powerpack and mounted on the front work surface) 1 HYTECH 4.11 Return Line Manifold with 2 Ports (Hard piped with powerpack and mounted on the rear work surface) 1 HYTECH 4.12 Test Line Manifold with 2 Ports (Hard piped with powerpack and mounted on the front work surface) 1 HYTECH 4.13 Pressure Gauge 0 to 100 Bar, Glycerin filled, 4 inch 1 Baumer / WIKA 4.14 Tray for Hydraulic Powerpack 1 NA 5 Basic Hydraulic Module 1 5.1 Pressure Relief Valve (Direct operated relief valve) 2 Yuken / Rexroth 5.2 Flow Control Valve (Non Pressure Compensated) with Check Valve . 2 Yuken / Rexroth 5.3 Flow Control Valve (Pressure Compensated) with Check Valve 1 Yuken / Rexroth 5.4 Four way Three position manually operated direction control valve - Tandem Center 2 Yuken / Rexroth 5.5 Four way Three position manually operated direction control valve - Closed Center 1 Yuken / Rexroth 5.6 Three way Two position manually operated direction control valve - Closed Center 1 Yuken / Rexroth 5.7 Vertical Weight loading arrangement for hydraulic cylinder 1 set NA 5.8 Set of weights for loading arrangement 1 set NA 5.10 Single Acting Cylinder (Stroke: 100mm, Dia: 25mm, Test Pressure: 70 Bar) 1 Yuken / Rexroth 5.11 Double Acting Cylinder (Stroke: 200 mm minimum Test Pressure 130 Bar) 2 Yuken / Rexroth 5.12 Proximity Sensor Assmbly for Hydraulic Cylinder 6 NA 5.13 Cut Section models for Hydraulic components 1. Double Acting Hydraulic Cylinder 2. Pressure Relief Valve Direction Control Valve 1 HYTECH 6 Basic Hydraulic Module 2 6.1 Hydraulic Motor Bidirectional . 1 Yuken / Eaton 6.2 Needle Valve 2 Yuken / Polyhdron 6.3 Pressure Sequence Valve 1 Yuken / Rexroth 6.4 Pressure Reducing Valve 1 Yuken / Rexroth 6.5 Four way Two position manually operated direction control valve 1 Yuken / Rexroth 6.6 Check Valve Direct Operated 1 Yuken / Polyhdron 6.7 Single Pilot Operated Check Valve 1 Yuken / Rexroth 7 Circuit Design and Simulation Software 7.1 Automgen (IRAI France) - Hydraulic Circuit design and simulation software (Perpetual) 1 IRAI - France 8 Manuals for Basic Hydraulics 8.1 Operation Manual (Basic Hydraulics) 1 NA 8.2 Experimentation Manual (Basic Hydraulics) 1 NA 8.3 Hydraulics Text Book (Basic Hydraulics) 1 NA 9 Advance Hydraulics (Electrohydraulic) Module 1 9.1 Pressure Switch 1 Yuken / Rexroth 9.2 Four Way Three Position Double solenoid operated direction control valve 3 Yuken / Rexroth 9.3 Four Way Two Position Single solenoid operated direction control valve 1 Yuken / Rexroth 10 Advance Hydraulics (Electrohydraulic) Relay based operation module 10.1 2mm Patch cord connector set 1 set NA 10.2 Electrical Push button based power supply module 1 NA 10.3 Relay unit module (4 CO, 3Qty) 1 NA 11 Advance Hydraulics (Electrohydraulic) PLC Based operation module 11.1 PLC with 24 inputs and 16 outpts 1 Siemens 11.2 Power supply and control panel for PLC 1 Reputed Make 11.3 Control panel box with mounting for Advance Electrohydraulic Training Kit (1200 x 400 x 300mm) 1 NA 11.4 PLC Input module with input override switches (24 inputs) 1 HYTECH 11.5 Field input module (24 inputs) 1 HYTECH 11.6 PLC output module (24 outputs) 1 HYTECH 11.7 Field output module (24 outputs) 1 HYTECH 11.8 Remote operation unit with 2 selector switches, 2 push buttons and 2 mushroom head switches 1 NA 11.9 2mm Patch cord connector set 1 set NA 12 Workstation with Simulation software and licensed PLC software 12.1 Intel Mother board Computer with 21 inch LED Monitor (Acer / Dell) and bluetooth keyboard and mouse 1 ACER / DELL 12.2 IRAI Automgen software license (Perpetual) for hydraulic / electrohydraulic circuit design and simulation 1 IRAI - France 12.3 Necessary interface for direct operation of training kit from simulation software IRAI Automgen (Dynamic realtime simulation and operation) 1 HYTECH 12.4 Workstation operation unit with mounting facility 1 NA 13 Proportional Valve Training Kit Module 13.1 7 inch colour HMI 1 Siemens 13.2 High Pressure Filter 1 Reputed Make 13.4 Pressure Relief Valve (Subplate Mounted) with Locking Arrangement 1 Yuken / Rexroth 13.5 Pressure Line Manifold with 4 Ports (Hard piped with powerpack) 1 HYTECH 13.6 Return Line Manifold with 2 Ports (Hard piped with powerpack) 1 HYTECH 13.7 Test Line Manifold with 2 Ports (Hard piped with powerpack) 1 HYTECH 13.8 Pressure Gauge 0 to 100 Bar, Glycerin filled, 4 inch 4 Baumer / WIKA 13.9 Complete Piping arrangement 1 Set HYTECH 13.10 Hydraulic Cylinder with minimum 150mm stroke 1 HYTECH 13.11 Proximity Sensor Assmbly for Hydraulic Cylinder 6 NA 14 Proportional DCV Module 14.1 Proportional Direction Control Valve 1 Yuken / Argo Hytos 14.2 Control card for Proportional Direction Control Valve 1 Yuken / Argo Hytos 14.3 Four way Three position manually operated direction control valve 1 Yuken / Rexroth 15 Proportional PRV Module 15.1 Proportional Pressure Reducing Valve 1 Yuken / Argo Hytos 15.2 Control card for Proportional Pressure Reducing Valve 1 Yuken / Argo Hytos 15.3 Four way Three position manually operated direction control valve 1 Yuken / Rexroth

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review