Bench For Study And Training In Hydrostatic And Association Of Serial And Parallel Pump And Data Acquisition (DL HPC-4-CLS)

PL-624012

Workbench for load loss study. It has PVC pipes with different diameters to compare measurements, which are connected by means of flanges to allow their removal, if necessary.

The system is controlled via inverters, Venturi tube and tube for experiments, observations and Reynolds number calculations, which can be easily changed between smooth tubes, simply by replacing the flanges.

To drain unused water, the bank has well-placed hydraulic drains.

Didactic activities

The system allows the following experiments:

- Anti-discharge head research;

- Load loss study on different tubes, connections including smooth tubes, straight tubes of different diameters, hard expansion and contraction, 50 mm radius elbow, 100 mm radius elbow, 90° tube, length 45°, type "t" connection, type "y" connection;

- Study of flow measurement in different measuring instruments including at least: Use of the scale in a volumetric tank, Venturi meter; performance and efficiency of a centrifugal pump;

- Operation of the centrifugal pump;

- Head height measurement;

- Conversion between pressure - height;

- Pressure/flow characteristics of centrifugal pumps;

- Available suction height;

- Filling the pump;

- Sizing and selection of centrifugal pumps;

- Parallel operation characteristics of two similar pumps;

- Series operation characteristics of two similar pumps;

- Parallel operation characteristics of two similar pumps operating at different speeds;

- Series operation characteristics of two similar pumps operating at different speeds.

Goals

Experiences in hydrodynamics and observation of hydraulic phenomena, such as:

- Association of pumps in series and in parallel, such as:

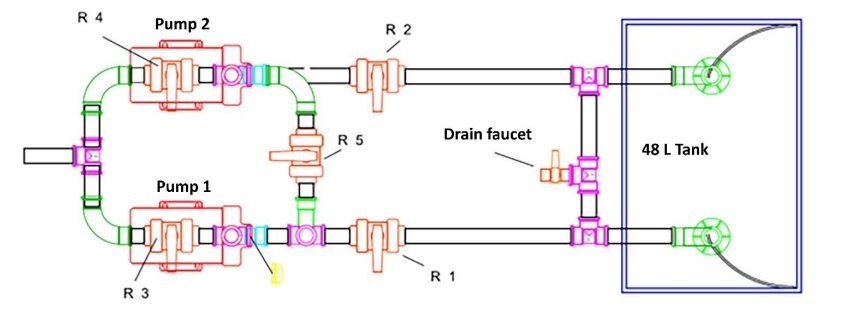

- Series connection of the pumps: R2, R4, R5 and R3 = Open with R4 and R1 = Closed.

- Parallel connection of the pumps: R1, R2, R3 and R4 = Open with R5 = Closed.

- Head loss in pipes and connections.

- Head loss in ascending lines and connections

- Head loss in tubular descent and connections

- Pressure comparison in pipes of different gauges (from ½ to 2 inches)

- Turbulence in rough pipe and smooth pipe

Devices:

- Inverter pumping control;

- Orifice plate with 3 mm central hole;

- Venturi in acrylic. Dimensions:

- Inner Ø 9 mm and inner stroke 60 mm;

- Outer Ø 27 mm and strokes of 36.5 mm at each end;

- 22 pressure measurement points;

- Manovacuometer;

- Bourbon manometer of 1, 2 and 3 kgf / cm2;

- Rotameter up to 8000 L / H;

- Pumping with open or closed system

- Observation and calculation of Reynolds number with clear acrylic tube with inkjet clips.

Technical characteristics

- Tank water capacity 48 L

- System water capacity (rest) 52 L

- Rated pipe diameter 32 mm

- Pump power 1 and 2 ½ HP

- Pumping capacity 4000 l/h/pump

- Rotameter capacity 8000 l/h.

- Three-Phase Electrical Voltage

Electric box with:

- Three-Phase Multimeter;

- HMI;

- Electrical controls and protections;

- Emergency button

Structure and finish

- The equipment features a strong extruded aluminum frame of 30 x 30 mm with yellow electrostatic paint and industrial nylon caps with good mechanical and impact resistance, versatile and removable.

- Bench built with high-quality products from a renowned commercial brand; therefore, its maintenance and repairs and spare parts are easy to find on the market.

The bench includes software and exercise manual.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review