Hydraulic double-sided test bench with variable displacement pump (DMSD-02)

PL-635135

Mobile teaching station is intended for conducting laboratory classes in the field of mechanics of machines and hydraulic drives. The position is intended for the simultaneous work of 8-10 participants. It allows you to learn the basic principles of power hydraulics, fluid mechanics and automation.

It can be used both to conduct professional exams in exact sciences and to train employees and maintenance staff in production plants. The stand has a mobile structure that allows it to be transported to various places and a modular structure that allows for building various schemes of hydraulic connections.

The components used on it are installed on the mounting wall and can be moved to different places. The width of the stand allows it to drive through standard door openings. The station can be powered with single-phase voltage 230 V from the standard electrical network.

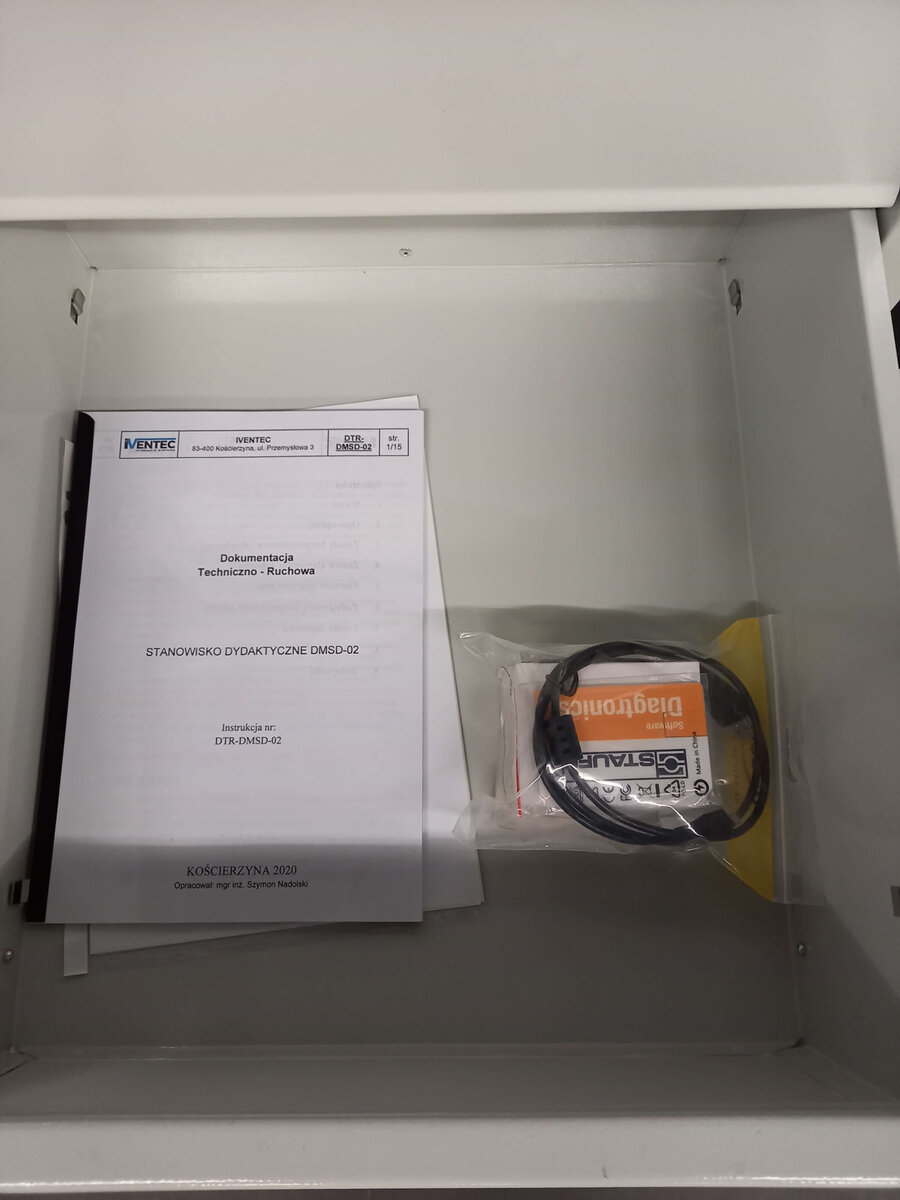

The equipment includes technical documentation and a set of exemplary laboratory classes that allow testing the characteristics of pressures, forces, speeds and flows of the tested hydraulic receivers.

A set of electric relays, switches and limit relays allows you to build industrial automation systems and explore technical knowledge. The components of well-known and reputable manufacturers are used to build the stands, guaranteeing long-lasting and trouble-free operation.

The basic parameters of the station:

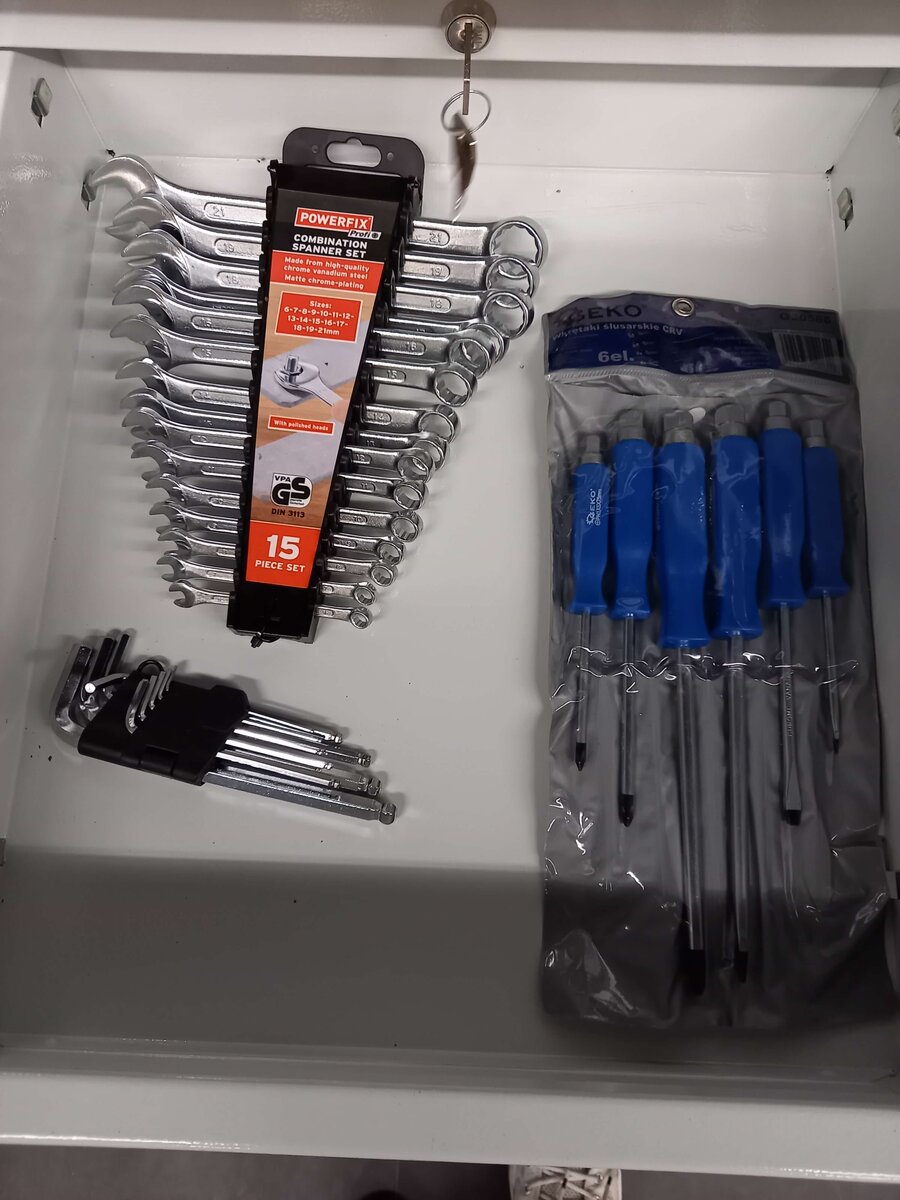

- Mobile assembly table with a double-sided work area, equipped with a container with drawers, a panel for mounting electrical relays, a holder for hanging diagrams and a hanger for hydraulic hoses

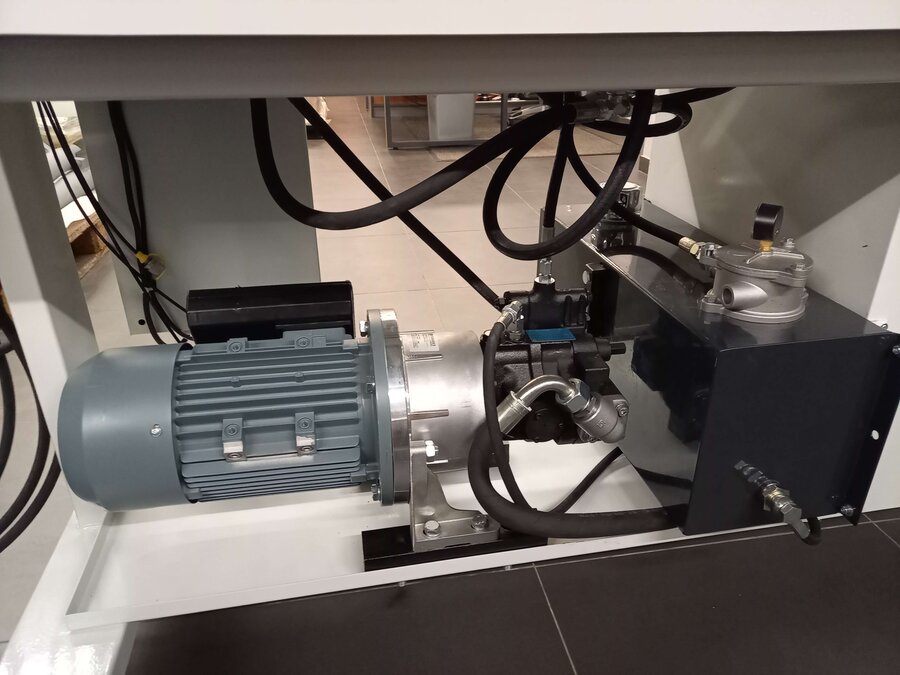

- Pump unit with a variable displacement piston pump with a Load Sensing regulator with a capacity of 11 l/min, a 230V, 50 Hz electric motor with a power of 2.2 kW, a pressure limiting valve and a solenoid valve for quick release of pressure from the system

- 25 L tank with return filter, breathing filter, oil level indicator

- Load Sensing pressure regulating valve

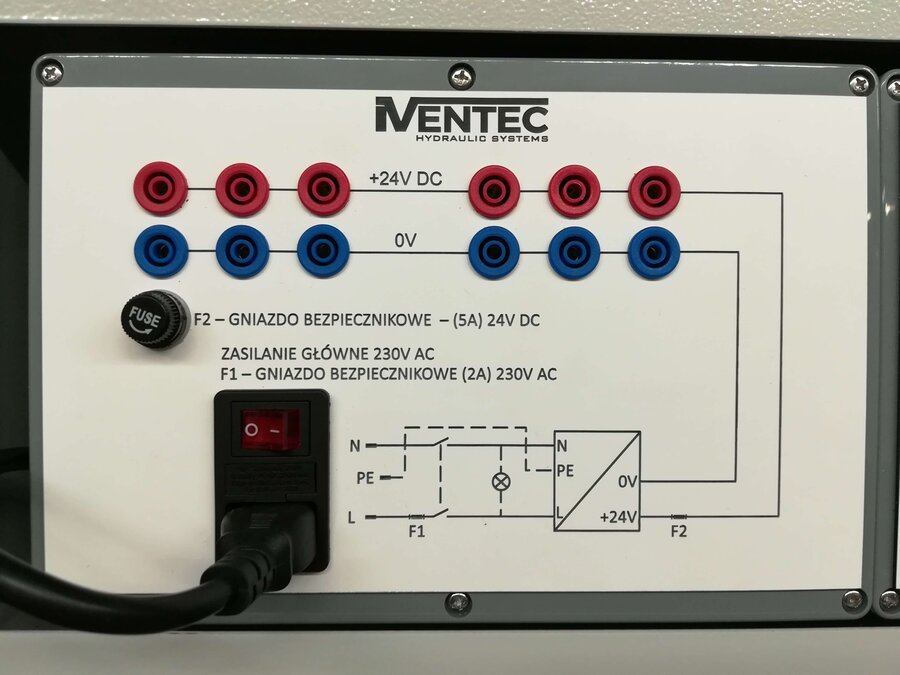

- Electric control panel controlling the operation of the power supply with overload protection

- Panel mounted current, voltage and power meter

- Power supply DC panel

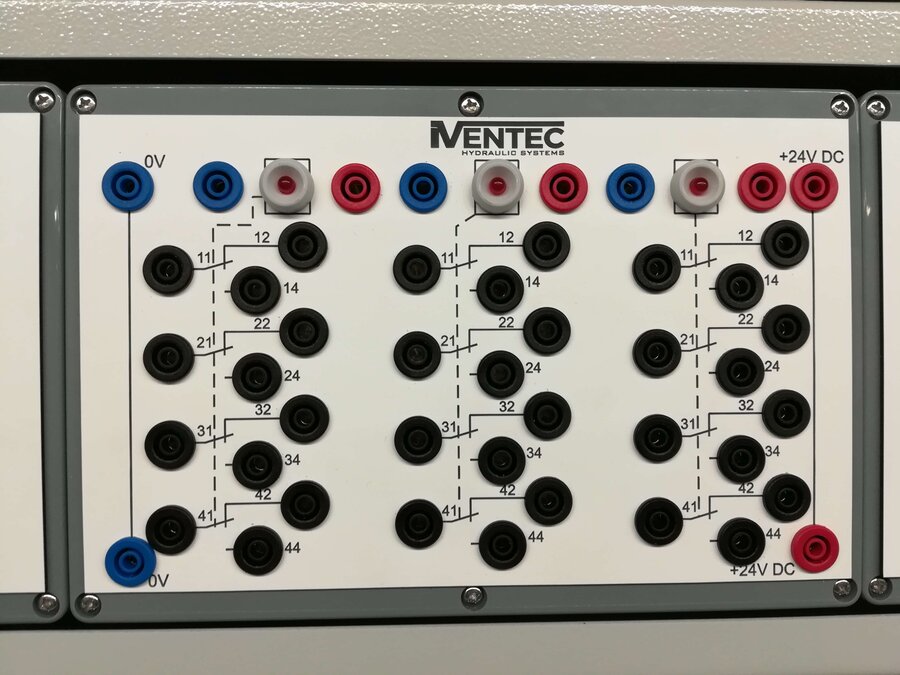

- Panel with set of electric relays

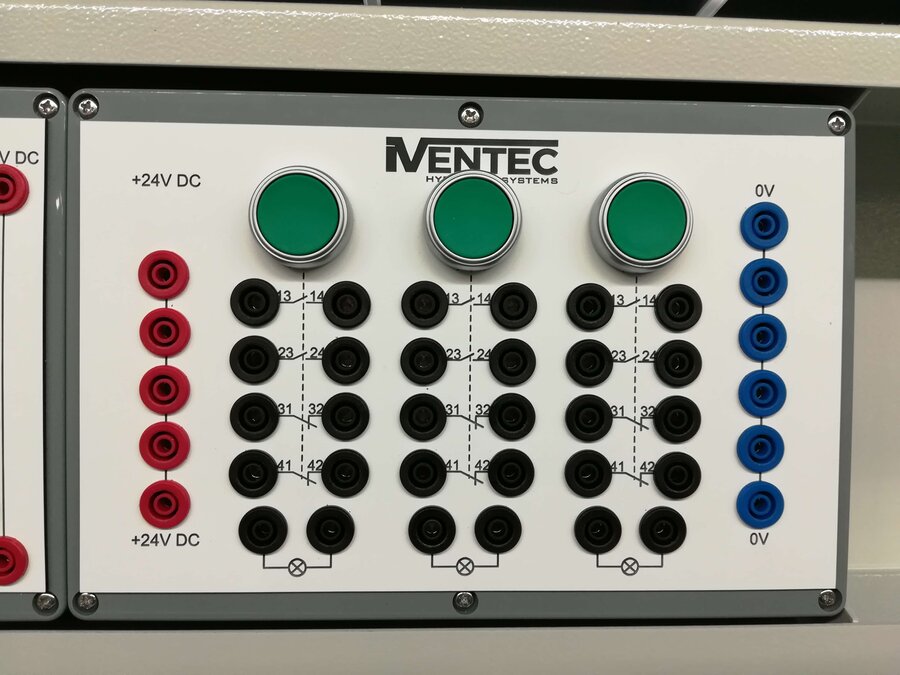

- Panel with electrical switches

- 2 x pressure and temperature transmitter with CAN bus signal

- 1 x turbine flow meter CAN bus

- 1 x electronic measurement panel with the possibility of exporting data to a computer

- 2 x manifold branching the pressure and return line with a built-in manual relief valve

- 1 x double-acting cylinder with variable load

- 2 x double-acting cylinder

- 4 x electric limit switch

- 1 x orbital motor

- 3 x pressure gauge with hoses and measuring connectors

- 2 x electric 4/3 directional valve

- 2 x manual 4/3 directional valve

- 1 x electric 4/2 directional valve

- 1 x manual 4/2 directional valve

- 2 x throttle check valve, sandwich version

- 2 x relief valve, sandwich version

- 2 x reducing valve, sandwich version

- 2 x throttle-check valve, in-line version

- 1 x check valve, in-line version

- 2 x check valve, in-line version

- 1 x flow divider, in-line version

- 12 x hydraulic hose with quick couplings

- 40 x electrical cable with 4 mm connectors

- A set of exemplary laboratory exercises

At the client's request, we can change the configuration of the station adapting to specific requirements.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review