Coupled Tank System ASTANK-2+ (L,F,P,T) (AA087.000.02)

PL-366793

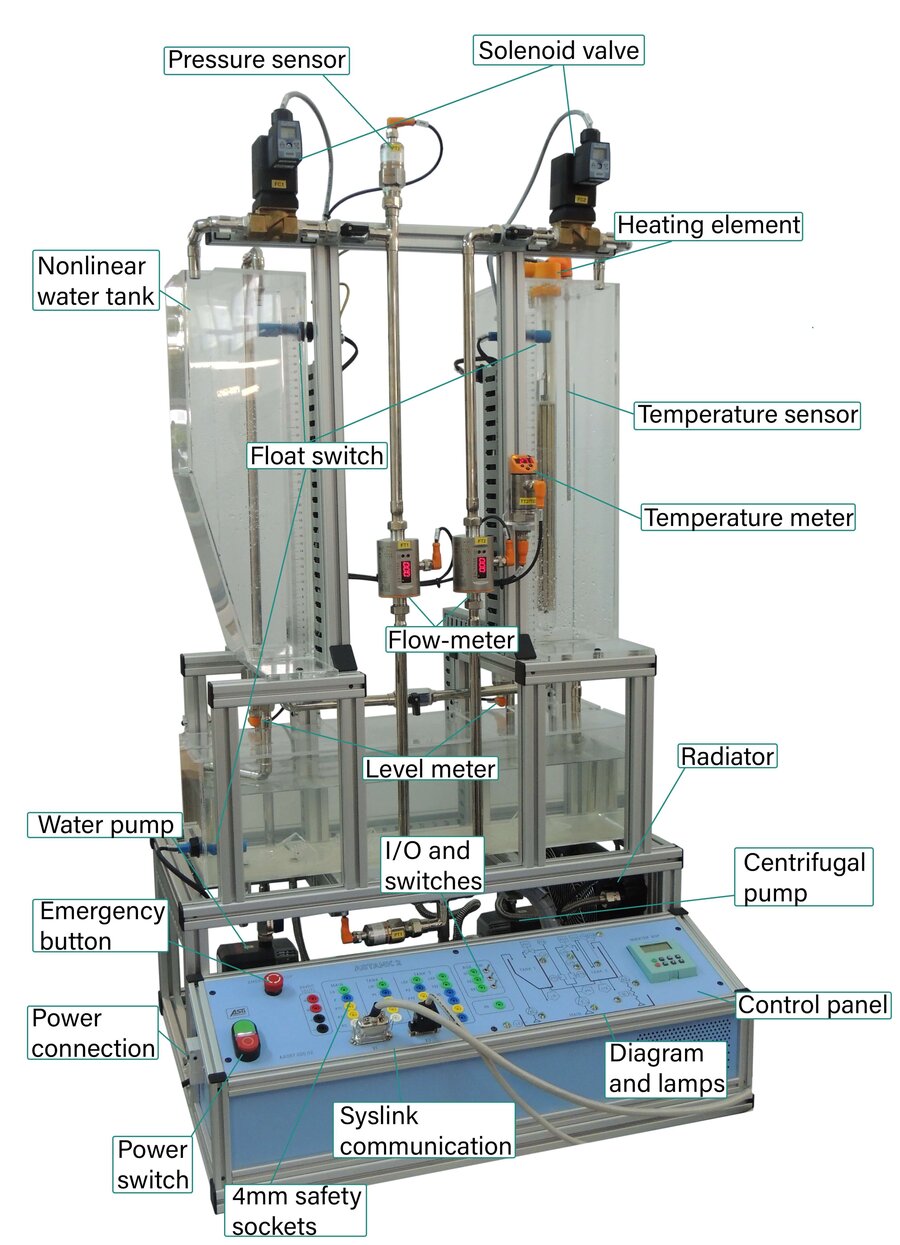

ASTANK 2 is an integrated platform for control techniques in systems engineering. It is designed to enable the application and testing of identification and control methods on a real process with non-linear behavior, described by fluid dynamics. Basically, it consists of a two open tanks system, between which fluid is circulated through a pumping and distribution network.

The equipment consists of:

Two interconnected graduated tanks, one with variable section;

- Collector tank;

- Two level transducers;

- Pumping and distribution network:

- frequency converter controlled pump;

- two constant flow auxiliary pumps;

- two pressure transducers for main pumping line monitoring;

- two flow transducers, one for each tank feeding line;

- two control valves (continuous electro-valves), one for each tank feeding flow adjust;

- three manual valves;

- Inverter driven pump;

- Auxiliary pumps;

- Heater;

- Temperature sensor and evaluation unit;

- Three level sensors (digital) for signaling filling / emptying limits;

- Front panel for manual operation and connection of signals.

ASTANK 2 enables its users to study and develop non-linear control strategies for flow and level processes.

With ASTANK 2 training equipment it is possible to do many experiments, such as:

- Study of the static and dynamic characteristics of transducers and actuators;

- Process data acquisition and conditioning;

- Analytic modeling and/or experimental identification of the processes;

- Designing of simple control structures (single controller of type P, PI or PID);

- Designing of multi-model control algorithms or for multi-variable processes;

- Implementation of adaptive structures for time-variant processes;

- Implementation of control strategies based on evolutionary techniques (fuzzy controllers, genetic algorithms, neural networks);

- Comparative study of control and robustness performance for the implemented algorithms.

This is why our equipment represents the best way to learn how to implement an automatic process control system on a PLC/PC.

Includes:

- INTERCONNECTED GRADUATED TANKS (one with variable section)

- COLLECTOR TANK

- BURKERT proportional VALVEs 24 V DC 18 W; CONTROL ELECTRONICS FOR SOLENOID VALVES

- SIEMENS SINAMICS FREQUENCY INVERTER.

- SIEMENS SINAMICS BASIC OPERATOR PANEL (BOP)

- IFM PRESSURE TRANSDUCERS

- IFM LEVEL TRANSDUCERS

- IFM FLOW TRANSDUCERS

- IFM TEMPERATURE TRANSDUCER with Display

- HEATER 1000W, 230V, stainless steel, length 500mm

- PUMP; CONSTANT FLOW AUXILIARY PUMPS; LEVEL SENSORS

- POWER SUPPLY 24 V DC, 3A

SIZE (W x H x D): 700 x 1300 x 600 mm

Net weight: 42.80 kg

THE PACKAGE ALSO INCLUDES: Power cable, User manual

RECOMMENDED: Safety connection cables 4mm, ASTANK-2+ Software Package

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review