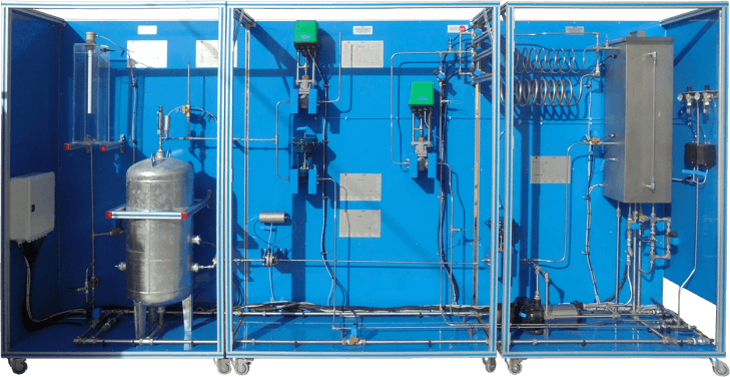

Computer Controlled Industrial Process Control Plant (CPIC)

PL-592465

The "CPIC" Computer Controlled Process Control Plant with Industrial Instrumentation and Service Module by EDIBON is a comprehensive unit designed to replicate the processes and instrumentation commonly used in industrial settings, all within a laboratory-scaled framework. This unit is specifically intended for studying the complexities of controlling variables in processes involving flow, temperature, level, and pressure.

The CPIC consists of a main unit where various industrial elements are installed and a service module that supplies essential utilities like hot and cold water, as well as compressed air, which are necessary for the unit's operation. This setup allows users to explore process control challenges and gain hands-on experience with systems often encountered in real-world industrial applications.

Equipped with EDIBON’s SCADA software, the CPIC includes a Control Interface Box, a Data Acquisition Board, and computer-based software packages for control, data acquisition, and data management. This comprehensive software integration enables users to monitor and control all relevant parameters within the system, providing a realistic and detailed study of process control techniques used across industries.

- CPIC. Unit:

- Anodized aluminum frame and panels made of painted steel.

- The unit includes wheels to facilitate its mobility.

- Main metallic elements made of stainless steel.

- Diagram in the front panel with distribution of the elements similar to the real one.

- Main Unit

- Service Module

The complete unit includes as well:

- Advanced Real-Time SCADA.

- Open Control + Multicontrol + Real-Time Control.

- Specialized EDIBON Control Software based on LabVIEW.

- National Instruments Data Acquisition board.

- Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

- Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

- Capable of doing applied research, real industrial simulation, training courses, etc.

- Remote operation and control by the user and remote control for EDIBON technical support, are always included.

- Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic and Software).

- Designed and manufactured under several quality standards.

- Optional ICAI software to create, edit and carry out practical exercises, tests, exams, calculations, etc. Apart from monitoring user’s knowledge and progress reached.

- This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

- CPIC/CIB. Control Interface Box.

- CPIC/CCSOF. PID Computer Control + Data Acquisition + Data Management Software.

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with 8 manuals. Required Services, Assembly and Installation, Interface and Control Software, Starting-up, Safety, Maintenance, Calibration and Practices Manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Familiarization with the different components of the system and their symbolic representation. Identification of components and description of their functions.

- The auxiliary systems: air and hot water supply.

- Flow sensors calibration.

- Temperature sensors calibration.

- Level sensor calibration.

- I/P converter calibration.

- Flow control loop (on/off).

- Flow control loop (proportional).

- Flow control loop (P+I).

- Flow control loop (P+D).

- Flow control loop (P+I+D).

- Adjust of the flow controller constants (Ziegler-Nichols).

- Adjust of the flow controller constants (reaction curves).

- Search of simple shortcomings in the loop of flow control.

- Temperature control loop (on/off).

- Temperature control loop (proportional).

- Temperature control loop (P+I).

- Temperature control loop (P+D).

- Temperature control loop (P+I+D).

- Adjust of the temperature controller constants (minimum area or reduction rate).

- Adjust of the temperature controller constants (minimum disturbance criterion).

- Adjust of the temperature controller constants (minimum width criterion).

- Study of the retards for speed/distance, exemplified through the temperature control loop.

- Study of the energy lost in the temperature control loop.

- Search of simple shortcomings in temperature control loop.

- Level control loop (on/off).

- Level control loop (proportional).

- Level control loop (P+I).

- Level control loop (P+D).

- Level control loop (P+I+D).

- Adjust of the level controller constants (minimum area or reduction rate).

- Adjust of the level controller constants (minimum disturbance criterion).

- Adjust of the level controller constants (minimum width criterion).

- Search of simple shortcomings in level control loop.

- Pressure control loop (on/off).

- Pressure control loop (proportional).

- Pressure control loop (P+I).

- Pressure control loop (P+D).

- Pressure control loop (P+I+D).

- Adjust of the pressure controller constants (minimum area or reduction rate).

- Adjust of the pressure controller constants (minimum disturbance criterion).

- Adjust of the pressure controller constants (minimum width criterion).

- Search of simple shortcomings in the pressure control loop.

- The use of the controllers in cascade, exemplified with the level/flow control loop.

- Adjust of cascade control constants (minimum area or reduction rate).

- Adjust of cascade control constants (minimum disturbance criterion).

- Adjust of cascade control constants (minimum width criterion).

- Search of simple shortcomings in cascade control loop.

- Practical operation of the control plant to some wanted specific values: transfers without interferences.

- Calculation of the fluid flow in function of the differential pressure sensor.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review