Industrial Electrical Installations Virtual Course (DL SMART-INDUSTRIAL)

PL-508224

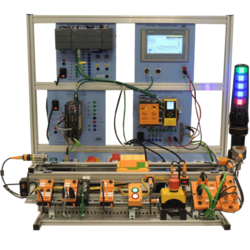

The DL SMART-INDUSTRIAL is a software that has been developed to teach multiple applications such as PLC, variable frequency drive, motor drives control and sensors in a unique and effective way.

With this software, students can improve their individual experience on studying electrical applications in practice.

Students will be able to develop several projects dealing with the following topics:

- Basic and advanced Industrial Installations;

- Basic and advanced motors starting;

- Motor starting with sensors;

- Motor starting and control with Codesys, TIA Portal and VFD;

This software will be able to reproduce the features and behaviours of the DE LORENZO Electrical industrial installations didactic systems.

With this type of software developed by DE LORENZO, students can learn at their own pace and teachers have more time to support the class, manage and improve the process because – unlike other simple simulators – it grants the following benefits:

- EFFECTIVE GUIDE FOR STUDENT

- AUTOMATIC VALIDATION OF STUDENTS’ TASKS

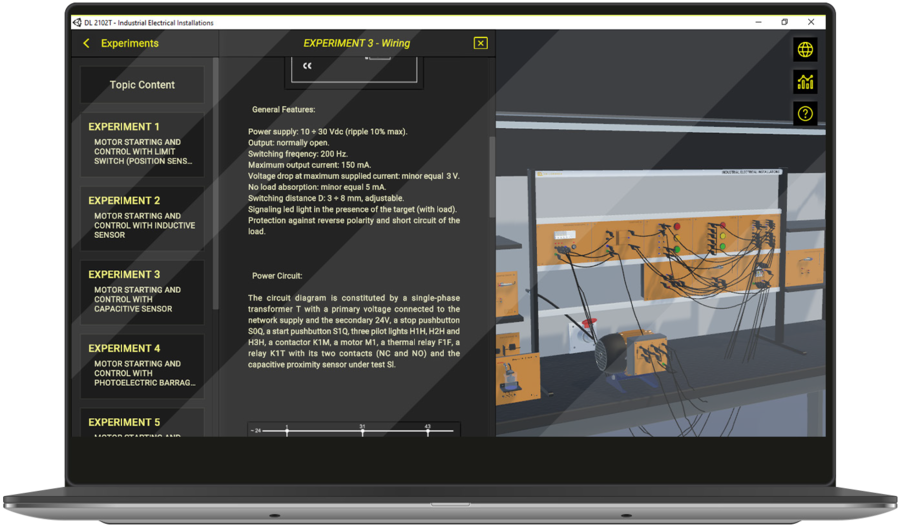

Possibility to access learning topics, with theory, instructions, and experiment proposals. The software includes a virtual version of the DE LORENZO Electrical industrial installations didactic systems; Student logs in, so his progress can be tracked, chooses one of the learning topics, accesses theory, experiments proposals and instructions.

The software automatically verifies if the student has completed successfully each task in order to allow him/her to go ahead with the next one. Student works on the assembly of the electrical machine, then makes the electrical connections and with all that correctly done, runs the experiment and answers questions about it

IT CONNECTS PROFESSOR, STUDENT, AND SCHOOL

De Lorenzo´s cloud server receives the students’ activities and provides reports and analytics to professors and institutions. Besides, a student can start working at school and continue at home or vice-versa. That means that the professors can monitor the students and based on the report that De Lorenzo´s cloud provides, the professors can give the support that a specific student might be needing.

COMPATIBLE WITH THE DL SMART-DASHBOARD (SOLD SEPARATELY)

PROFESSORS CAN FOLLOW STUDENTS PROGRESS

The professor can do and access everything the student can. Besides, he/she can also access the dashboard’s portal. It includes interesting reports and analytics that help the professor to monitor the group in real time, as well as to identify students who are doing very well, as well as those who need help, who are not working at all and who seem to be “cheating”.

Tasks report

This is an important tool since it provides evidence of the activities a student worked on. That means the school has evidence of the practical activities the distance learner has done with detailed information about it.

PROFESSORS CAN SEE WHICH STUDENTS ARE ON SCHEDULE

With this interface, the professor may choose which groups he/she wants to monitor, to verify who is on schedule, who is pending and so on. It is possible to define the expected progress percentage in relation to the tasks available in the course.

RHYTHM

This other dashboard shows the number of activities the students did daily and weekly. The professor may decide to verify it regarding a whole group/class or a specific student.

TRIALS PER TASK

This chart helps the teacher to understand which task may be the most difficult and which one may be the easiest in order to adjust the deadlines.

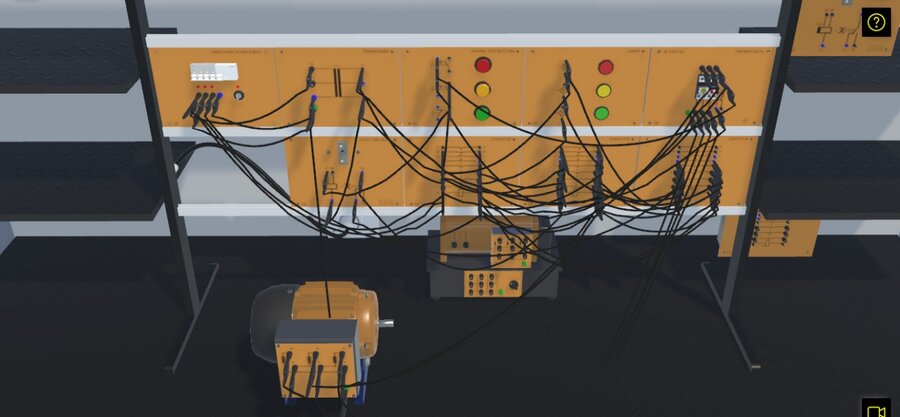

- IT’S A 3D SIMULATOR

- IT HAS BUILT-IN EXPERIMENTS

- THE PROJECTS INCLUDE GUIDANCE

- + CONTENTS AND SUPPORT MATERIALS, SO THEY CAN LEARN BY THEMSELVES

- IT AUTOMATICALLY CHECKS STUDENT ACTIVITIES TO LET THEM MOVE ON, LIKE IN A GAME

- PROFESSORS CAN MONITOR STUDENTS AND VERIFY WHICH POINT THEY NEED HELP(Option available with the Dashboard)

HOW DOES IT HELP THE PROFESSOR?

With this software, the teacher spends less time explaining topics, verifying students’ activities and helping students to identify mistakes that do not allow the successful completion of the experiment.

That means that the professor has more time to manage the class, help students who need more attention and make improvements. The two following points grant such benefits:

- The software automatically verifies the experiments carried out by the students and it gives relevant feedback:

- The software tracks the students’ progress, and it allows exporting reports:

Like in a game that has different phases with challenges and missions, the DL ELECTRICAL INSTALLATION software includes practical experiments that need to be successfully completed to let the student access the next one.

The teacher does not need to verify continuously if the student carried out the experiment. Moreover, many questions students would make about “What could be wrong?” are automatically “answered” by the software when the student does not perform the experiment successfully. The image below summarizes this process.

At any time, the professor may verify how many and, specifically, which experiments the student has completed. That report can be used to track students’ activities and it can be considered as an evaluation tool.

This report can be generated and displayed directly in the system or it can be exported to a spreadsheet (see image below).

DIDACTIC EXPERIENCE AND APPLICATION

The software guarantees a complete experience in the field of several electrical installations. Students can approach this topic starting from the basic concepts, such as basic industrial installations, up to advanced experiments such as motor starting and control using PLC.

Through this system, it is possible to assemble a relevant number of electrical applications to carry out the following didactic experiences:

- Basic industrial installations

- Advanced industrial installations

- Basic motors starting

- Advanced motors starting

- Motor starting with sensors

- Motor starting and control with codesys

- Motor starting and control with TIA PORTAL

- Motor starting and control with inverter (VFD)

SET OF COMPONENTS

The system is based on a set of components that allow the assembly of installations. The set consists of the following components:

- Power supplies

- Transformers

- Sensors

- Switches

- Toggle buttons

- Push buttons

- Relays

- Contactors

- Starters

- Motors

- VFD

The system PLCs also includes lamps, level control, pulse counters, etc., in order to perform all the experiments.

LEARNING TOPICS

This software covers 8 topics and proposes 44 experiments for the students. The experiments are listed below, grouped by learning topics.

BASIC INDUSTRIAL INSTALLATIONS

With this kit, it is possible to perform the following experiments:

- Single - pole control auxiliaries

- Contactor

- Logical operators (and)

- Logical operators (or)

- Logic operators (not)

- Contactor self - supply

- Interlock between contactors

- Sequentially controlled contactors

- Exclusive - or operator

- Static excitation delayed timer

- Static de-excitation delayed timer

- Static eletronic timer

Smart simulator environment with 12 experiments regarding basic usage of contactors and timer relays, by applying both in several different combinations, each one including brief theoretical mentions and practical diagrams of the main circuits that are used in industrial electrical installations. Each one is divided into three steps: Assembly of the modules that will be used, wiring connections and simulation. After the simulation, the student will have to answer an assessment form related to the experiment in order to unblock the next one.

ADVANCED INDUSTRIAL INSTALLATIONS

With this kit, it is possible to perform the following experiments:

- Thermal relay

- Manual star/delta starting

- Manual reverser

- Timed sequence control

- Pulse generator

- Automatic star/delta starter

- Star/delta starter with reverser

- Counter - current braking

Smart simulator environment with 8 experiments regarding different ways to start an asynchronous induction motor, both manually and automatically with the help of a time relay, each one including brief theoretical mentions and practical diagrams of the main circuits that are used in industrial electrical installations. Each one is divided into three steps: Assembly of the modules that will be used, wiring connections and simulation. After the simulation, the student will have to answer an assessment form related to the experiment in order to unblock the next one.

BASIC MOTOR STARTING

With this kit, it is possible to perform the following experiments:

- Manual starter with rotor resistances

- Automatic starter with rotor resistances

- Speed variator for Dahlander motor

- Speed variator and reverser for Dahlander motor

- Three-phase induction motor’s rotation direction automatic inverter

Smart simulator environment with 5 experiments regarding the basics of motor starting, each one including brief theoretical mentions and practical diagrams of the main circuits that are used in industrial electrical installations. Each one is divided into three steps: Assembly of the modules that will be used, wiring connections, and simulation. After the simulation, the student will have to answer an assessment form related to the experiment in order to unblock the next one.

ADVANCED MOTOR STARTING

With this kit, it is possible to perform the following experiments:

- Motor starting with switch

- Y/Δ Starting with switch

- Starting and reversal with switch

- Y/Δ Starting with 2 rotation directions, with switch

- Speed variator for Dahlander motor with switch

- Speed variator for Dahlander motor, 2 rotation directions, with switch

Smart simulator environment with 6 experiments where the student will move forward in the previous topic and learn more advanced subjects about motor starting, each one including brief theoretical mentions and practical diagrams of the main circuits that are used in industrial electrical installations. Each one is divided into three steps: Assembly of the modules that will be used, wiring connections, and simulation. After the simulation, the student will have to answer an assessment form related to the experiment in order to unblock the next one.

MOTOR STARTING WITH SENSORS

With this kit, it is possible to perform the following experiments:

- Motor starting and control with limit switch (position sensor)

- Motor starting and control with inductive sensor

- Motor starting and control with capacitive sensor

- Motor starting and control with photoelectric barrage sensor

- Motor starting and control with photoelectric reflecting sensor

- Motor starting and control with magnetic level sensor

- Motor starting and control with level variations

- Motor starting and control with pulse programmer

Smart simulator environment with 8 experiments regarding how to start motors with the help of sensors, each one including brief theoretical mentions and practical diagrams of the main circuits that are used in industrial electrical installations. Each one is divided into three steps: Assembly of the modules that will be used, wiring connections, and simulation. After the simulation, the student will have to answer an assessment form related to the experiment in order to unblock the next one.

MOTOR STARTING AND CONTROL WITH PLCS (CODESYS)

With this kit, it is possible to perform the following experiment:

- Introduction to PLC programming

- PLC automation basics

- Automatic motor starting using PLC

- Remote controlled starting of a three-phase asynchronous motor with double controls

- Remote controlled reversal of a three-phase asynchronous motor

- Star-delta remote controlled starting of a three-phase asynchronous motor

- Star-delta remote controlled starting with remote controlled reversal

- Remote controlled bias switch for a two speed motor (Dahlander connection)

- Remote controlled reversing switch and remote controlled bias switch for two speed motor

Smart simulator environment with 9 experiments regarding how to start and control motors using a Programmable Logic Controller Software (Codesys), each one including brief theoretical mentions and practical diagrams of the main circuits that are used in industrial electrical installations. Each one is divided into three steps: Assembly of the modules that will be used, wiring connections, and simulation. After the simulation, the student will have to answer an assessment form related to the experiment in order to unblock the next one.

MOTOR STARTING AND CONTROL WITH PLCS (TIA PORTAL)

With this kit, it is possible to perform the following experiment:

- Introduction to PLC programming

- PLC automation basics

- Automatic motor starting using PLC

- Remote controlled starting of a three-phase asynchronous motor with double controls

- Remote controlled reversal of a three-phase asynchronous motor

- Star-delta remote controlled starting of a three-phase asynchronous motor

- Star-delta remote controlled starting with remote controlled reversal

- Remote controlled bias switch for a two speed motor (Dahlander connection)

- Remote controlled reversing switch and remote controlled bias switch for two speed motor

Smart simulator environment with 9 experiments regarding how to start and control motors using a Programmable Logic Controller Software (TIA Portal), each one including brief theoretical mentions and practical diagrams of the main circuits that are used in industrial electrical installations. Each one is divided into three steps: Assembly of the modules that will be used, wiring connections, and simulation. After the simulation, the student will have to answer an assessment form related to the experiment in order to unblock the next one.

MOTOR STARTING AND CONTROL WITH VFD

With this kit, it is possible to perform the following experiments:

- Simple start/stop

- Setting acceleration/deceleration time

- Simple jog mode experiment

- Jog mode in steady-state operation

- Closed loop speed regulation (PID control)

Smart simulator environment with 5 experiments regading how to start and control motors using a Variable Speed Drive (VFD), each one including brief theoretical mentions and practical diagrams of the main circuits that are used in industrial electrical installations. Each one is divided into three steps: Assembly of the modules that will be used, wiring connections, and simulation. After the simulation, the student will have to answer an assessment form related to the experiment in order to unblock the next one.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review