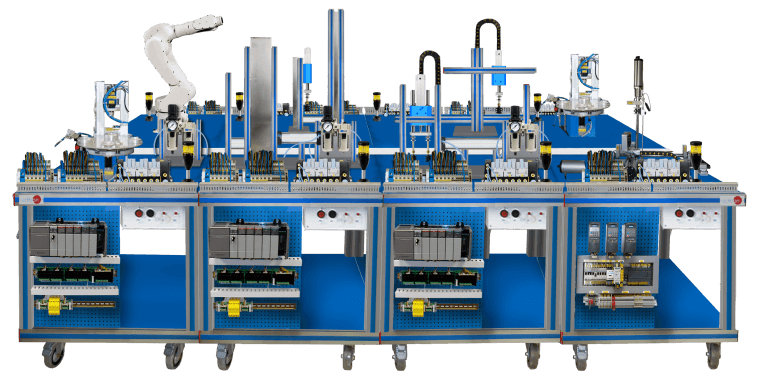

Flexible Manufacturing System 1 (AE-PLC-FMS1)

PL-727102

The Flexible Manufacturing System 1, “AE-PLC-FMS1,” by EDIBON is a modular automation system comprising several key workstations, including the Feeding Workstation for Pieces “AE-PLC-A,” Mounting Workstation “AE-PLC-M,” Automatic Pressing Workstation “AE-PLC-P,” Rotary Table Workstations “AE-PLC-MR1” and “AE-PLC-MR2,” Automatic Screw Workstation “AE-PLC-AT,” Robotic Arm Workstation “AE-BR,” Storage Workstation “AE-PLC-AL,” and Linear Transport Workstation “AE-PLC-T.”

The AE-PLC-FMS1 system automates the assembly process by supplying a base part and mounting multiple components onto it, followed by screwing and finally storing the assembled piece in a designated storage area. Here is an overview of the process sequence:

- Feeding Workstation: This station prepares the base parts with the correct dimensions and positions them on the linear transport system.

- Mounting Workstation: Another component is added to the base piece after a verification check, and it is then positioned on the transport system.

- Pressing Workstation: A hydraulic cylinder presses the newly mounted component into the base piece.

- Rotary Table Workstations: These two stations each add unique pieces of various colors, sizes, and materials to the base piece.

- Automatic Screw Workstation: Four screws are placed into the base piece.

- Robotic Arm Workstation: The robotic arm installs an automatic screwing tool to secure the screws into the mounted components.

- Storage Workstation: Finally, an automated manipulator transports the assembled part to its designated position in storage.

Each workstation operates autonomously via a local PLC, while a central PLC oversees coordination across the system. Communication between workstations and the central PC is established through an Ethernet protocol.

Designed to support the learning of automation fundamentals, the AE-PLC-FMS1 system offers practical training in areas such as PLC programming, Ethernet network operation, and technologies like pneumatics, electro-pneumatics, and vacuum systems. The optional “AE-AS” software allows students to practice real-world automation software skills through 2D and 3D process simulations, SCADA system supervision and control, PLC programming, and hydraulic, pneumatic, and electronic device simulations.

- AE-PLC-FMS1. Unit:

*Available PLC models of different manufacturers: PANASONIC, SIEMENS, OMRON, MITSUBISHI, ALLEN BRADLEY, etc.

- AE-PLC-PAN-UB. PANASONIC PLC Base Unit.

- N-ALI02. Domestic Power Supply.

- N-CPU-PAN. Panasonic CPU Module.

- PLC-PAN-K1, PANASONIC PLC Kit 1 (Optional).

- N-MT. Test module.

- PLC-PAN-K2, PANASONIC PLC Kit 2 (Optional).

- N-ESA-PAN. Panasonic Analog I/O Module.

- N-SWT-4.4 Ports Ethernet Switch Module.

- PLC-PAN-K4, PANASONIC PLC Kit 4 (Optional).

- N-HMIA-PAN. Panasonic Large HMI Module.

- N-SWT-4. 4 Ports Ethernet Switch Module.

- PLC-PAN-K5, PANASONIC PLC Kit 5 (Optional).

- N-MOD. Modem Communication Module.

- N-SWT-8. 8 Ports Ethernet Switch Module.

- AE-AS. Automation Systems Simulation Software. (Optional).

The complete unit includes as well:

- Advanced Real-Time SCADA.

- Open Control + Multicontrol + Real-Time Control.

- Specialized EDIBON Control Software based on LabVIEW.

- National Instruments Data Acquisition board.

- Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

- Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

- Capable of doing applied research, real industrial simulation, training courses, etc.

- Remote operation and control by the user and remote control for EDIBON technical support, are always included.

- Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic and Software).

- Designed and manufactured under several quality standards.

- Optional ICAI software to create, edit and carry out practical exercises, tests, exams, calculations, etc. Apart from monitoring user’s knowledge and progress reached.

- This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

- PLC, HMI and web server programming software.

- Component Workstations.

- SAC. Silent Air Compressor Unit

- HPU. Hydraulic Power Unit

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with 8 manuals. Required services, Assembly and Installation, Interface and Control software, Starting-up, Safety, Maintenance, Calibration and Practices manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Introduction to flexible manufacturing system (FMS).

- Introduction to pneumatics and electro-pneumatics.

- Introduction to vacuum technology.

- Study of the sensor detection.

- Testing the digital inputs and outputs of the automatic system through a PLC.

- Modify manufacturing parameters through the PLC.

- Configuration of a pneumatic application.

- Introduction to the Human-machine interface systems (HMI).

- Study of an automatic control of an industrial system.

- Control of the flexible manufacturing system through a central PLC in an Ethernet network with local PLC in each workstation.

- Manage the flexible manufacturing system through the HMI device.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review