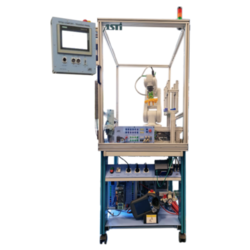

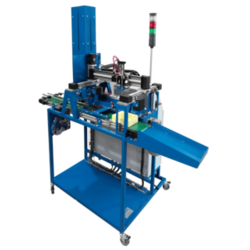

AGV with Cobot (AG10)

PL-312862

Training on collaborative mobile robotics, programming the 6-axis robot and mobile platform

The AGV MiR100 ErmaSmart is a mobile robotic system for automating the movement of materials, components and finished products in a workshop.

It responds to calls from operators or production machines with needs to supply or send parts.

The UR eSeries collaborative arm (Model UR5) on the AGV MiR100 enables robotic gripping of boxes or trays for loading / unloading from the AGV platform without human intervention.

The list of jobs assigned to the MiR100 can be accessed and modified by the production supervisor.

Learning of collaborative mobile robotics, programming of the UR5e 6-axis robot (850mm radius, 5kg load) and MIR100 mobile robot

Technical solutions:

- Driving activities

- Systems management

- Industrial maintenance, robotics

- Automation of internal logistics flows

Features:

- MIR100 mobile platform with 2 individually controlled wheels and two lithium-ion batteries for mobile operation

- Bluetooth and Wi-Fi wireless communication

- Low and high detection cameras

- Set of containers for transporting parts

- Gripper or Suction cup and autonomous on-board vacuum generator (Optional)

- Schunk tool changer (Optional)

- 2D industrial vision Sensopart (Optional)

- RFID traceability system (Optional)

Educational activities:

- Automation & Robotics

- Functional and structural analysis of the system

- Robot programming with intuitive dedicated software

- Programming of travel missions

- Programming of associated complementary peripherals (vision, RFiD)

- Mobile robotics safety and risk analysis

- Production management

- Use of the AGV for the transfer of parts between two production stations

- Industrial maintenance

- Preventive maintenance

- Improving maintenance (modification of gripping jaws and 3D printing, etc.)

Strong points:

- True industrial system with modern robotic technologies

- Easy programming of mobile and collaborative robots

- Introduction to logistics production flows and their optimization

- System usable in training courses in robotics, industrial maintenance, management & control of automated production systems

- Possible extensions to the flexible ErmaSmart production line

References:

- AG10: AGV MiR100 ErmaSmart with UR5 eSeries collaborative arm

- AG11: Modbus-TCP IO-Link master and RFiDIO-Link transceiver

- UR17: OnRobot RG2 collaborative electric gripper option for Cobot Station

- UR18: Option gripper by suction cup and on-board Schmalz vacuum generator for Cobot Station

- UR12: Option VisorRoboticV10 monochrome 2D vision sensor (Brand: Sensopart) at the end of the robot arm, for Cobot Station

- UR13: Option VisorRoboticV20 color 2D vision sensor (Brand: Sensopart) at the end of the robot arm, for Cobot Station

Technical Specifications:

- UR5e 6-axis robot (850mm reach, 5kg load, 1m/s speed)

- MIR100 mobile platform (100 kg max payload, 1.5 m/s max speed) with 2 individually driven wheels and 2 lithium-ion batteries for nomadic approach

- Bluetooth and Wi-Fi communication

- Low and high detection cameras

- Set of trays for transporting parts

- Gripper or vacuum cup and embedded autonomous vacuum generator (optional)

- Sensopart 2D industrial vision (optional)

- RFID tracking system (optional)

- Automatic charging station (optional)

UR5e 6-axis robot (850mm reach, 5kg load, 1m/s speed)

MIR100 mobile platform (100 kg max payload, 1.5 m/s max speed) with 2 individually driven wheels and 2 lithium-ion batteries for nomadic approach

Bluetooth and Wi-Fi communication

Low and high detection cameras

Set of trays for transporting parts

Gripper or vacuum cup and embedded autonomous vacuum generator (optional)

Sensopart 2D industrial vision (optional)

RFID tracking system (optional)

Automatic charging station (optional)

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review