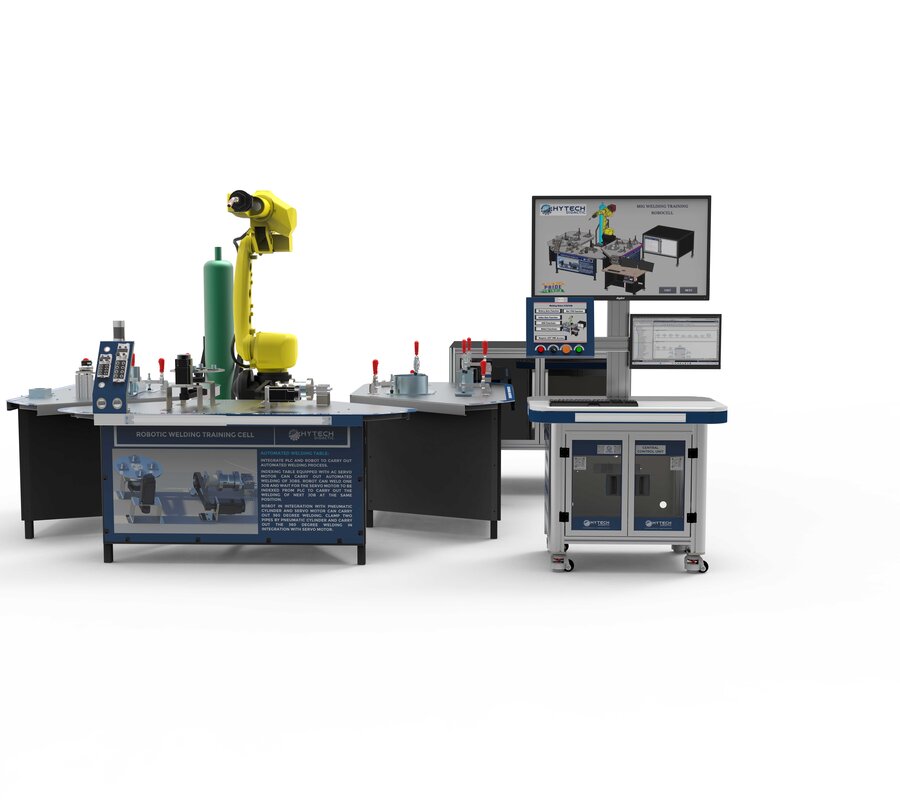

Integrated Robotics Welding Cell with PLC, HMI and IIOT (MIG Welding Robocell)

PL-115497

The Industrial Welding Robocell developed by Hytech Didactic is a comprehensive training and industrial simulation setup featuring: • An industrial welding robot with a minimum reach of 1000 mm, integrated with a Central Control Unit equipped with PLC, HMI, and IIOT. • The robot can be programmed using a teach pendant or via offline programming software that also functions as a digital dynamic twin, providing real-time simulation and control. A dedicated TV screen displays the digital twin for enhanced visualization and training. The setup includes: • Three individual experiment tables, each made of mild steel with an aluminum top to facilitate easy removal of welding splatter. • A mobile control unit (aluminum extrusion frame) housing the welding controller, stepdown transformer, and robot controller. • A trolley for the gas cylinder and mounting for the feeder cable, ensuring complete mobility and safety. Equipped with an industrial welding source (e.g., Fronius), the system provides real-world welding capabilities. Additional industrial features include: • I/O link communication with smart light indicators, enhancing hands-on learning. • Profinet-based communication between the robot controller and the machine control panel, replicating real industrial environments. This robocell is ideal for technical institutions, vocational training centers, and Industry 4.0 labs, offering practical experience in robotic welding, automation, and smart manufacturing systems.

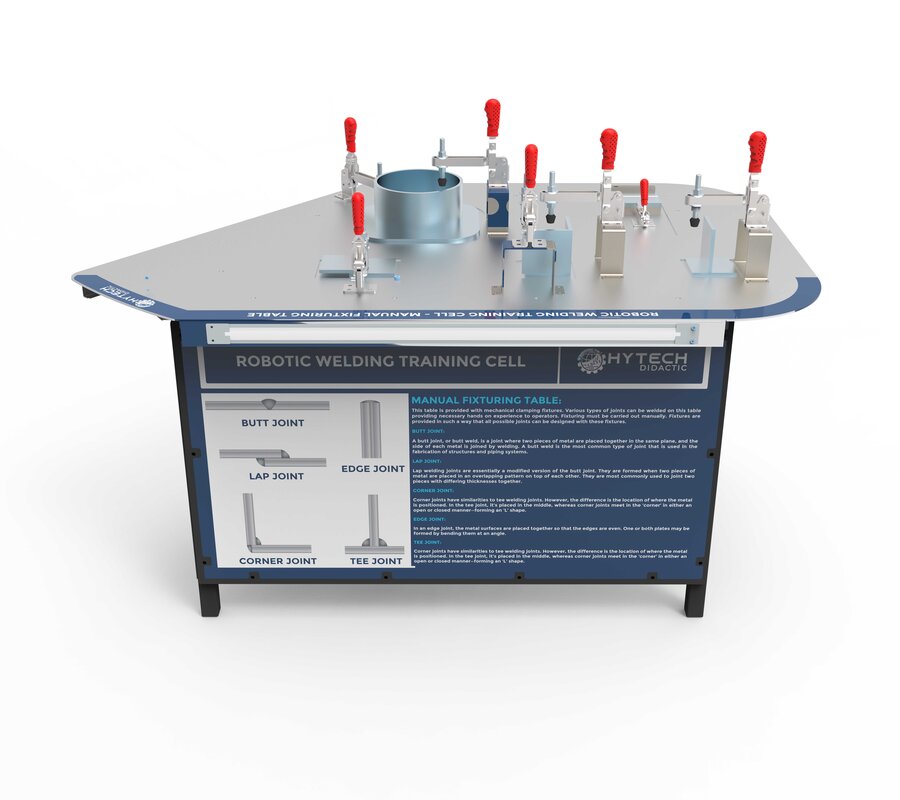

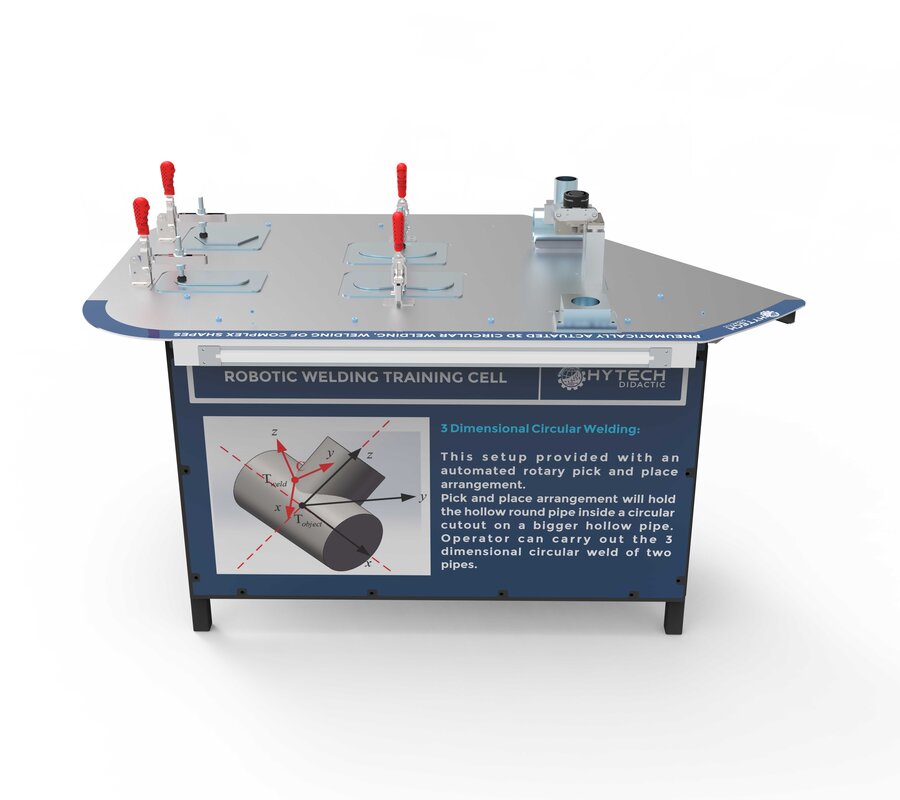

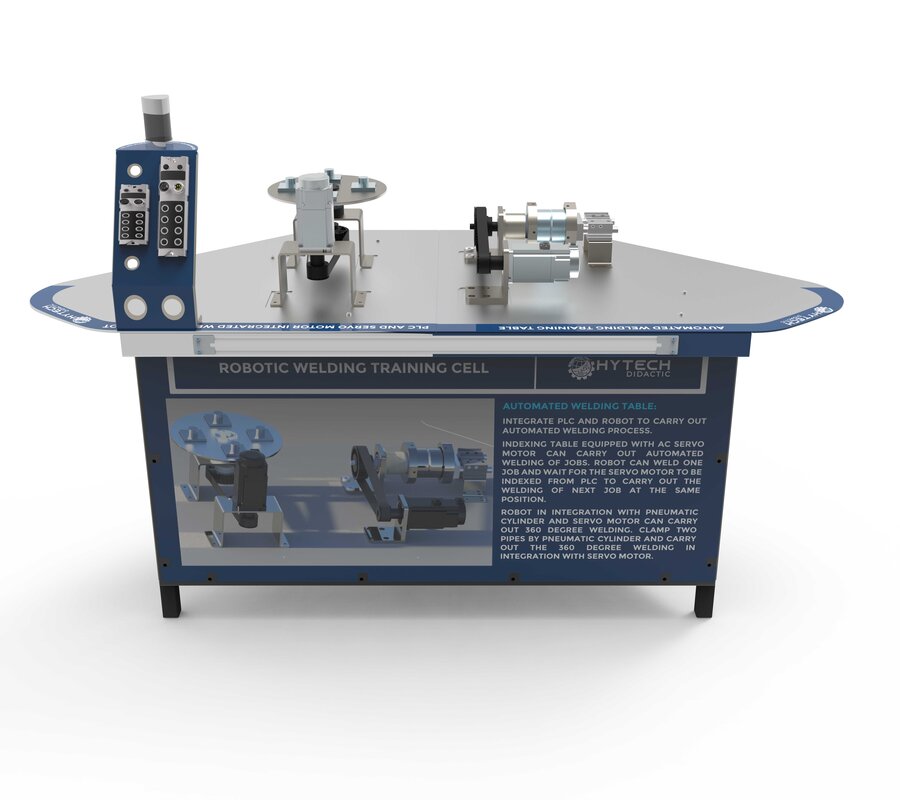

🦾 Robotic Setup • Industrial Welding Robot (e.g., Fanuc Arc Mate) with: o Minimum 1000 mm reach o 12 kg payload capacity • Robot programming via Teach Pendant and Offline Programming (OLP) software • Supports Digital Dynamic Twin for real-time 3D simulation ________________________________________ 🧠 Control & Automation • Central Control Unit with: o PLC (Siemens S7-1200 / Mitsubishi FX5) o HMI (IIOT-based; Siemens KTP 700 / Mitsubishi GS) • Profinet and I/O Link communication with Smart Lights • Integration with Servo Motors and Pneumatic Valves for automated workflows ________________________________________ 🔌 Offline Programming & Simulation • Compatible with: o Fanuc Roboguide o Siemens Technomatix • Enables offline programming and testing without halting live production ________________________________________ 🧪 Experiment Tables (3) 1. Table 1 – Basic Weld Joints Table o Welds: Butt, Corner, Edge, Lap, T-joint o Equipped with mechanical clamping arrangements 2. Table 2 – Automated Welding Table (Setup 1) o Includes indexing table with AC servo motor o Robot welds sequential jobs indexed by PLC command 3. Table 3 – 3D Circular Welding Table (Setup 2) o Pneumatically actuated pick-and-place unit inserts pipe into pipe o Robot performs 3D circular welding of hollow pipes ________________________________________ 🧰 Hardware & Accessories • Fronius / Lincoln Welding Source • Mobile control unit with: o Robot Controller o Welding Controller o Stepdown Transformer • Aluminum extrusion frame, gas cylinder trolley, and feeder cable mounts • Aluminum sheet top on all tables for easy removal of weld splatter ________________________________________ 🌐 Smart & Industry 4.0 Features • IIOT Integration • Real-time process visibility through TV screen displaying digital twin • Designed for Industrial Training, Skill Development, and Smart Manufacturing Labs

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review