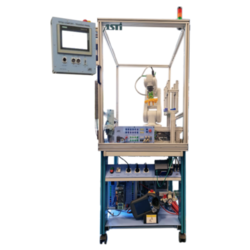

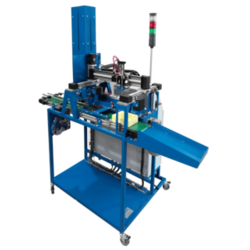

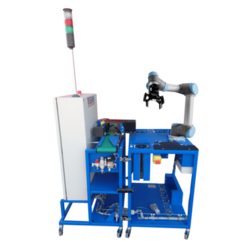

Industrial Robotics Lab - COBOT Training Cell with PLC HMI and IIOT (COBOT Cell)

PL-795538

The Hytech COBOT Cell is a comprehensive training platform integrated with a Central Control Unit featuring PLC, HMI, and IIoT connectivity. It enables users to learn both standalone COBOT operations and advanced applications involving PLC and HMI integration with IIoT capabilities. At the core of the cell is the Mitsubishi ASSISTA COBOT, equipped with a pneumatically operated automatic tool changer. The COBOT can autonomously switch between three different pneumatic gripper tools, enabling it to perform a variety of tasks without manual intervention. The training setup includes four experiment tables mounted on a robust aluminium extrusion frame. The COBOT can be operated through a teach pendant or a touch pad, providing users with diverse control methods. A built-in 3D simulation software functions as a digital dynamic twin, allowing for offline programming and virtual testing of COBOT operations. Additionally, the complete 3D environment and real-time COBOT movement are dynamically displayed on a TV screen mounted on the training cell, offering an engaging and interactive learning experience.

Structure Fabricated using high-strength aluminium extrusions Outer Dimensions: 1700 mm (L) × 1300 mm (W) × 800 mm (H) Equipped with 4 castor wheels featuring brakes and anti-vibration mounts Horizontal work surface made with aluminium extrusions Robot controller cabinet integrated with electrical control panel for robot operations Transparent safety door with door-latching interlock switch for added safety Robot Compatible with KUKA / FANUC / Mitsubishi COBOTs Includes Teach Pendant for programming and control Minimum Payload Capacity: 5 kg Minimum Reach: 900 mm Integrated Electrical Gripper (e.g., Schunk) for collaborative operations Digital Twin Integration Complete setup provided in STP format for offline 3D modeling and simulation Fully integrated with Siemens Tecnomatix and Visual Components for offline robot programming Central Control Unit Separate structure built with aluminium extrusions Top Surface Dimensions: 720 mm × 100 mm Work surface made using a combination of aluminium extrusions and MDF Equipped with 4 castor wheels (braked and anti-vibration type) Full-fledged electrical control panel with industrial-grade PLC Transparent front doors with safety interlocking switch Mounting arrangement for LED TV / Monitor / HMI using aluminium extrusions Control System: PLC: Siemens S7-1200 / Mitsubishi FX5 series HMI: Siemens MTP700 / Mitsubishi GT2110 Software License: Siemens TIA Portal (latest version, Perpetual License) IIoT Capability: Siemens Industrial Edge (Optional) I/O Link Master with minimum 8 ports Smart Light with I/O Link compatibility HMI mounting with control push buttons: CYCLE START, CYCLE RESET, EMERGENCY STOP Computer System: Industrial Workstation (Intel i5) with 21” Monitor, OR High-Performance Laptop, both preconfigured with the training system Wireless Keyboard and Mouse Modular Training Tables Table 1: Conveyor with RFID-Based Sorting Conveyor with DC geared motor and pneumatically actuated auto feeder Minimum Travel Length: 500 mm Minimum Width: 70 mm I/O Link-based RFID Reader/Writer RFID Tags: 08 pcs Workpieces with RFID mounting: 08 pcs Pallet for RFID-tagged workpieces Table 2: Load and Colour-Based Sorting I/O Link Colour Sensor Load Cell with analog output and digital set point Workpieces: 06 pcs in three different colours 06 pcs in three different weights Pallet for sorted workpieces Table 3: Collaborative Assembly Pallet integrated with photo sensors: 08 pcs Workpieces for practical assembly tasks Automatic Screwdriver for robotic-assisted assembly Bolts and fasteners for hands-on applications Table 4: Tool Changer Table Robot Side Tool (1 Qty) Tool Side Clamping (Qty: 03) Vacuum Gripper with Vacuum Generator Pneumatic Parallel Gripper (Qty: 02) Mounting arrangement for grippers made in aluminium extrusions Optional Digital Twin Software Packages Option 1: Siemens Tecnomatix (1 Seat) – 1-Year Subscription License (License deactivates after 1 year) Option 2: Visual Components (15 Seats) – Perpetual License with 1-Year AMC (License remains active permanently; updates available for 1 year)

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review