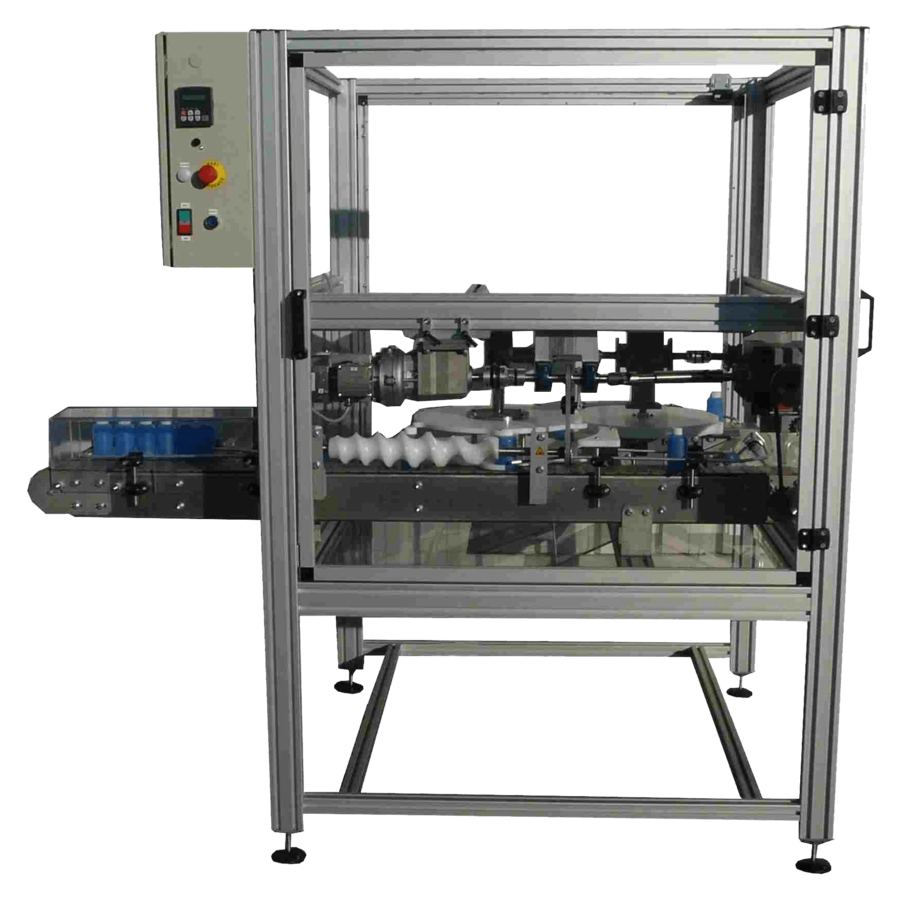

Degroupeur (DE10)

PL-949251

This is a hands-on industrial training system for alignments and transmissions study and maintenance.

Features:

- Conversions of movements (Angle gearboxes, Bearings, Gears, Pinions, Belts, Chains ...)

- Electrical energy (LV switchgear, Variator, Asynchronous motor)

- Sensors (Photoelectric)

- Programmable robot

- Mechanical measuring instruments (Vibration, Alignment

Educational activities:

- Ideal product for maintenance activities in the fields of alignment and mechanical transmission

- Assembly, disassembly and adjustments of the transmissions used

- Fault diagnosis using industrial measuring devices

- Observation of the influence of a misalignment on a system

- Dynamic functional tests of mechanical operations performed by students

- Implementation of industrial shaft alignment instrumentation and vibration study

- Wide variety of mechanical components

- Functional analysis and study of unbundling construction solutions (3D Solidworks delivered with the product)

- Kinematic studies and sizing of the main elements

- Remote control cabinet for electrical wiring and automation activities

Strong points:

Product based on an industrial reality (System for unbundling a stream of flasks or bottles within a production line) allowing students to be made aware of the problems related to the alignment of shafts, pulleys, gears and belt and chain tension

Wide variety of mechanical components

References:

- DE10: Mechanical ungrouper and its power box

- DE11: Remote control cabinet for DE10 automation

- DE30: Mechanical ungrouping device with a control cabinet and a power cabinet including 3 removable plates for motor starter wiring

- DE19: Option: Mechanical kit: short conveyor in kit

- DE18: Specific tools

Associated products:

- DE13: Drainable corner drive case

- DE21: Corner drive case without constraint

- DE14: Shaft alignment measurement instrumentation with set of shims

- DE15: Instrumentation for vibration analysis and detection of defects

- DE16: Pulley / pinion alignment measurement instrumentation and belt tension

Technical Specifications:

- Siemens PLC

- Speed drive and asynchronous motor

- Training on: angle transmission / shafts, pulleys, gears alignment / belt and chain tension / vibration analysis

- Format change (jars / bottles) modifying the worm screw and star-wheels

- Mounting, dismounting and adjustments (angle transmission, conveyor, pulleys alignment and belt tension, gear alignment and chain tension…)

- Observation of the impact of a misalignment on the system and correction

- Improvements (changing the transmission, adding sensors, implementing a counter…).

Siemens PLC

Speed drive and asynchronous motor

Training on: angle transmission / shafts, pulleys, gears alignment / belt and chain tension / vibration analysis

Format change (jars / bottles) modifying the worm screw and star-wheels

Mounting, dismounting and adjustments (angle transmission, conveyor, pulleys alignment and belt tension, gear alignment and chain tension…)

Observation of the impact of a misalignment on the system and correction

Improvements (changing the transmission, adding sensors, implementing a counter…).

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review