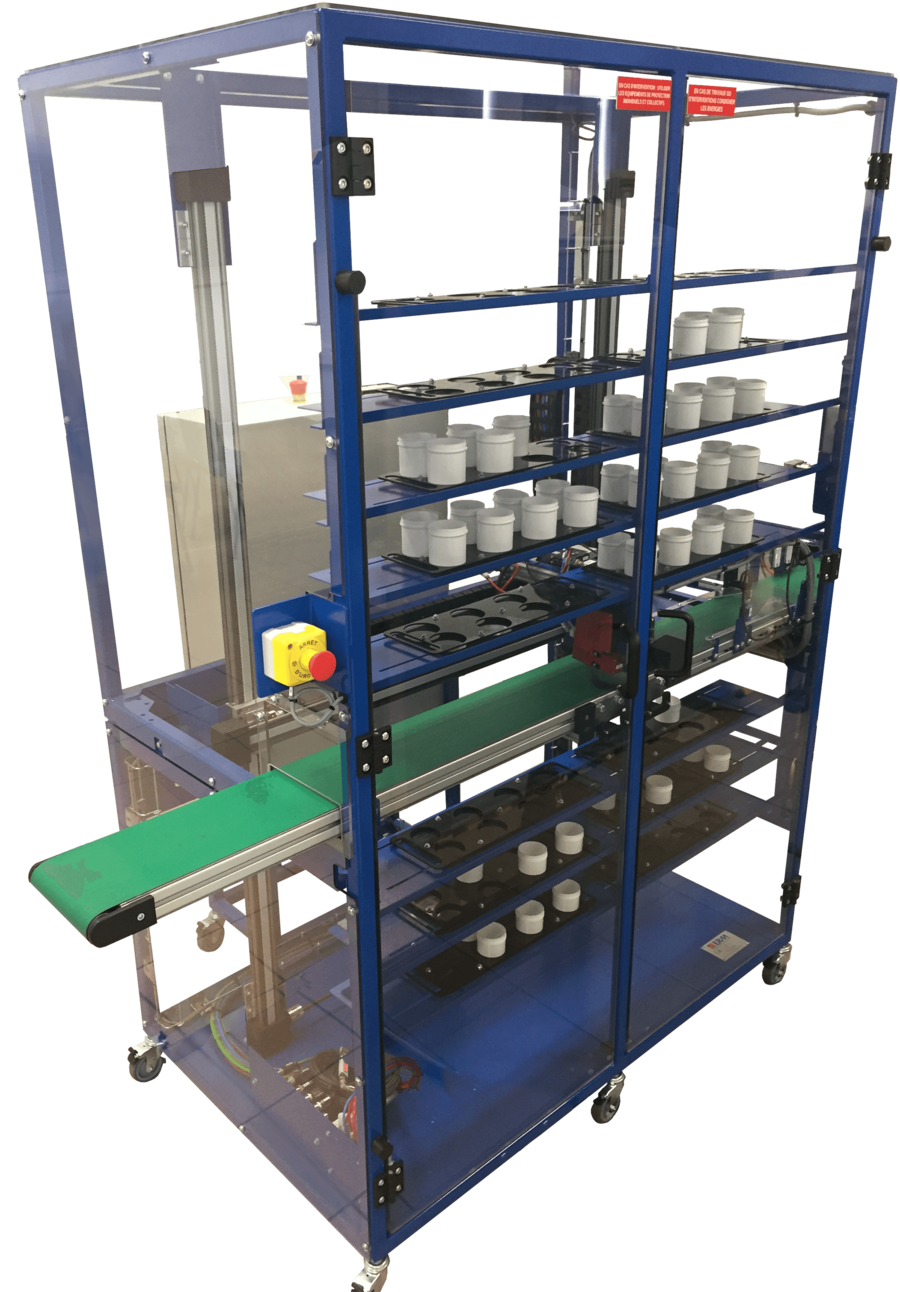

Dynamic vertical store (VL10)

PL-554526

This is an automated system for order preparation (storage and picking of trays / boxes)

Description of the system:

The Dynamic Vertical Warehouse system is an automated sales order preparation system. It provides dynamic storage and destocking of trays or boxes / pallets. In order to prepare an order, he can combine stored trays or boxes / pallets and just-in-time trays or boxes / pallets. It thus makes it possible to address the concepts of stock, minimum production quantity, just-in-time ...

It integrates a system of 2 Cartesian axes XZ very often used in industrial vertical warehouses. The functions and components are derived from real industrial components used in the logistics industry.

This Dynamic Vertical Warehouse system (ref VL10) designed in the spirit of the industry of the future (Industry 4.0) meets the main requirements on the intelligence and evolution of production methods:

Flexibility & Personalization with the possibility of individual order preparation

IoT & Communications with the writing of RFID Tags for the identification and traceability of packages from the customer order.

This automated system can be used independently with trays or boxes / pallets, but also be integrated into the flexible ErmaSmart production line.

The main functions of the Dynamic Vertical Warehouse (VL10) are:

- Convey the trays or boxes / pallets from the inlet to the gripping station, and possibly let them go to the outlet of the conveyor in case of "just-in-time" production

- Place the trays or boxes / pallets in the location of the vertical store indicated (Automatic placement or at a location specified by the MES) by associating the RFID number of the trays or boxes / pallets and the store location number

- Recover the trays or boxes / pallets in the registered locations to prepare an order with stock, checking that the RFID number of the tray or box / pallet entered is the one requested

- Evacuate the trays or boxes / pallets to the outlet

- This training system is mainly intended for driving activities, systems management, industrial maintenance, electrical engineering, automation and mechanics.

This product is accompanied by a technical and educational file in digital format.

"Industry 4.0" topics covered:

- Scalability & Flexibility

- Customization

- Simplified programming

- Digital twin

- Mobile robotics

- Collaborative robotics

- Efficient Actuators

- CAPM & CMMS

- Digital instructions & MES

- "Online" quality control

- IOT & Communications

- Big Data, AI & Predictive Maintenance

- Augmented reality

- Virtual reality

- Additive manufacturing for tools ...

Educational activities:

- Electrical engineering

- Discovery and handling of the system (functional analysis and study of system technologies)

- Control of the electrical quantities of the system (network, power supply, drive, XZ axis commands, programmable logic controller, man-machine interface and control circuit).

- Commissioning and validation of the operation of the system (of the different production modes)

- Adjustment and configuration of the installation components (asynchronous geared motor and its frequency converter, XZ axis control)

- Wiring of new sensors and actuators (improvement and / or replacement of an electrical component of the installation)

- Programming of new PLC and Human Machine interface cycles (TIA Portal software supplied).

- Diagnosis of one or more malfunctions

- Use of digital tools and communication

- Automatisms

- Functional and structural analysis of the system

- Programming of vertical warehouse axis orders

- Programming of production cycles (TIA Portal software delivered with the system)

- Programming of the man-machine interface (TIA Portal software delivered with the system)

- Implementation of IO-Link sensors (Input / output reassignment ...) and the IO-Link vacuum generator

- Production management

- Production management with choice of packaging method (in boxes or trays)

- Change of production format

- Traceability and logistics with the writing of RFID Tags

- Development of operator assistance procedures

- Optimization of production with digital tools 4.0

- Industrial maintenance

- Preventive maintenance (conveyor, suction, etc.)

- Corrective maintenance (fault diagnosis using the TIA PORTAL basic software delivered with the cell, rapid manufacturing of 3D printing tools, etc.)

- Improved maintenance (addition of sensors on the conveyor, new format of boxes, trays, etc.)

- Mechanical

- Study of a workstation with linear axes, ergonomics, dimensioning of axes and actuators ...

- Design of 3D printed parts

Strong points :

- True industrial system with modern technologies (Cartesian robot XZ, IO-Link, Ethernet, Profinet, RFID ...)

- Production flexibility with the storage of different trays and boxes / pallets

- Traceability of the customer's order with writing and reading RFID Tags

- Introduction to industrial logistics techniques

- System usable in the fields of electrical engineering, industrial maintenance, and driving, control of automated systems

- Supplied with Siemens TiaPortal programming software for programming the PLC and the dialogue terminal

- IO-Link technology with Profinet IO-Link master (IFM brand) and software for supervision / parameter setting of

- LR Device sensors and IO-Link smart sensors (RFID, Vacuum generator, photoelectric sensor, etc.)

- Possible extensions to the flexible ErmaSmart production line

References :

- VL10: Vertical dynamic magazine with module for gripping and storing trays (ErmaSmart "Conditioning"), boxes / pallets (ErmaSmart "Assemblage") and standard boxes of components (Stand alone version)

- UC90: Fault box option for electrical box, configurable remotely on tablet (Not supplied)

- UC51: Option Visual instructions & Monitoring of production indicators on the open application environment Tulip and touchscreen tablet, for one machine (With 3-year subscription to Tulip Pro, € 1170 excl. tax per year beyond)

- UC52: Option Visual instructions on the open application environment Tulip and touchscreen tablet, for one machine (With 3-year subscription to Tulip Standard, 570 € HT per year beyond)

- UC41: Siemens remote console option on iPad tablet (Included)

- IO01: Electrical and pneumatic measurement sensors (IO-Link) option for monitoring the power, flow and electrical and pneumatic consumption of a machine equipped with an IO-Link master and supervision and preventive maintenance software

Technical Specifications:

- 2-axis Cartesian robot with stepper motors (brushless option upon request)

- S7-1200 PLC & KTP700 touchscreen (Siemens)

- IO-Link Master & Smart sensors

- Light curtains

- RFID traceability

- Gripping by pneumatic cylinder and vacuum cup or gripper

2-axis Cartesian robot with stepper motors (brushless option upon request)

S7-1200 PLC & KTP700 touchscreen (Siemens)

IO-Link Master & Smart sensors

Light curtains

RFID traceability

Gripping by pneumatic cylinder and vacuum cup or gripper

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review