Ermapompes (PO20)

Vendor

Edquip Product Code

PL-750569

Quality Certification

CE

Warranty

12 months

Student product ratio

1 - 8

Production leadtime

80 days

Content languages

English,

French

Taining types

In person,

Live online,

Documentation

X.X (product not reviewed yet)

Write review

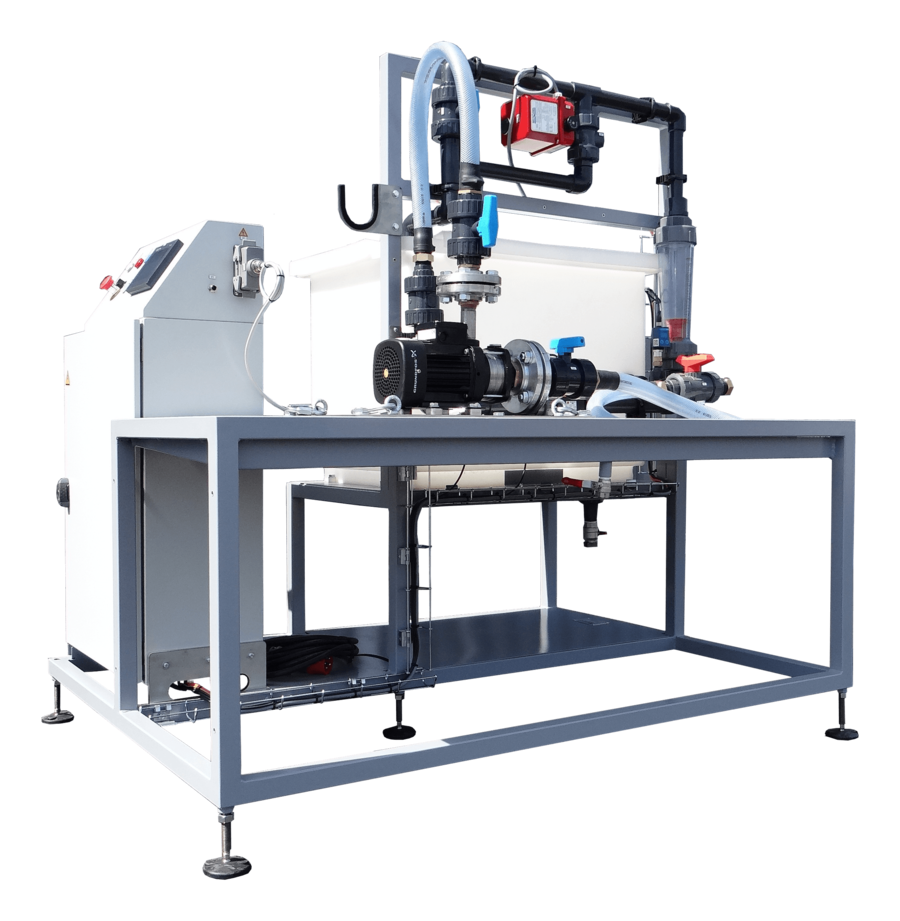

Study, maintenance and testing bench for industrial pumps

Features :

- Industrial pumps(centrifugal, lobe, sewage, etc.)

- Control valves (solenoid valves)

- Sensors and measures (flow, pressure, torque, voltage, current)

- Control and command (Webserver controller, speed drive)

Training activities:

- Functional analysis, studying the technologies used and constructive solutions (3D modeling on SolidWorks)

- Hydraulic connection, commissioning, tightness testing and pump performance testing (flow/pressure, vibration, acoustics, etc.)

- Assembly, disassembly and adjustments (e.g., Shaft alignment of standard centrifugal pump, cleaning, etc.)

- Controlling mechanical stress and heavy handling (e.g., Laying/removing pumps on/from the test bench)

- Monitoring, inspections, diagnostics, corrective maintenance and improving maintenance (Direct or speed drive) motor starter wiring

- Studying the speed drive configuration and performance

- Energy consumption and efficiency study (with / without speed drive)

- Analysis of the test device (information chain) and controller and embedded Web supervision programming

Key points:

- The product is adapted for trainings in electrotechnics, control and maintenance

- Automatic curve of the pressure/flow characteristics of industrial pumps

- Unique support for maintenance training in water-related trades and process industries

- Spare parts are supplied with each pump

- Mechanical operations can be validated through functional testing

- Multiple workstations: One test bench for several pumps

References :

- PO20 : Maintenance and tightness testing bench

- MV11 : Workshop crane (Optional)

- PO21 : Standard centrifugal pump

- PO22 : Multi stage horizontal centrifugal pump

- PO23 : Sewage pump

- PO24 : Displacement pump

- PO25 : Diaphragm dosing pump

- PO15 : Mechanical tool kit

- PO16 : Maintenance measuring tools

Technical Specifications:

- 5 industrial pumps (centrifugal, sewage, peristaltic, diaphragm dosing)

- Control valves

- Sensors and measurements (flow, pressure, torque, voltage, current)

- PLC with HMI and webserver

- Speed drive

- Automatic curve of the pressure/flow characteristics of industrial pumps

- Spare parts are supplied with each pump

- Mechanical operations can be validated through functional testing

5 industrial pumps (centrifugal, sewage, peristaltic, diaphragm dosing)

Control valves

Sensors and measurements (flow, pressure, torque, voltage, current)

PLC with HMI and webserver

Speed drive

Automatic curve of the pressure/flow characteristics of industrial pumps

Spare parts are supplied with each pump

Mechanical operations can be validated through functional testing

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review

Power requirements

1 phase, 200 VAC – 240 VAC/50 Hz

Other requirements

Warranty

12 months

HS code

Equipment dimensions (L/W/H)

Equipment weight

Production lead time

80 days

Teacher materials available

Yes

Student materials available

Yes

E-Learning modules

No