Handling Robocell with PLC - HMI - IIOT (Industrial Handling Robocell)

PL-809494

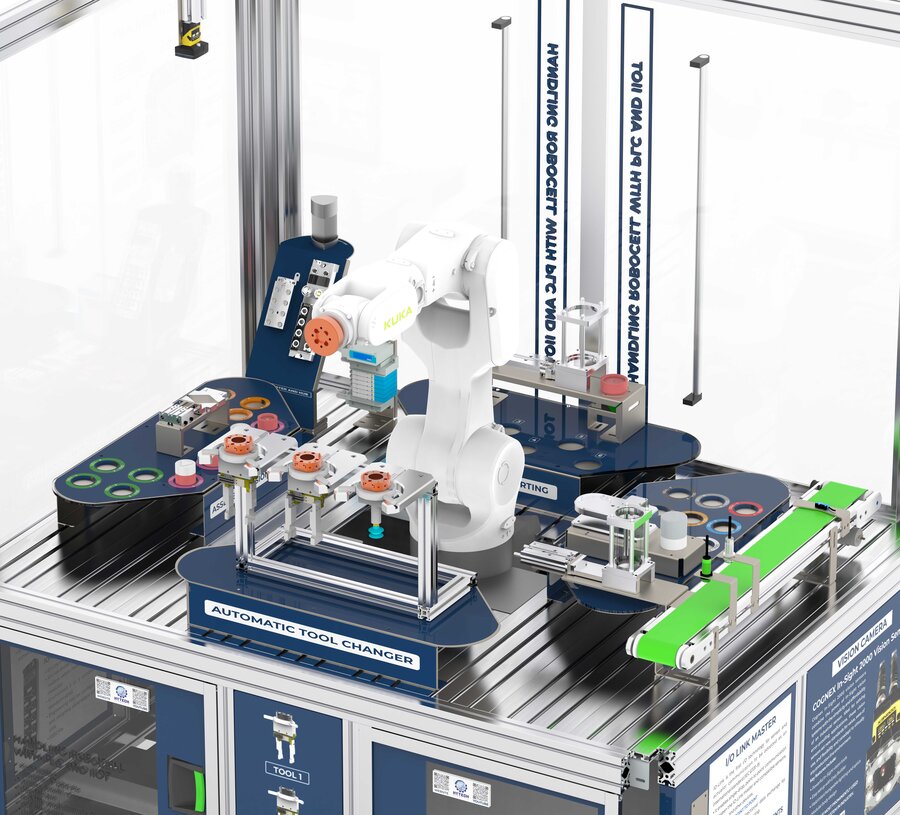

🔹 Overview The Handling RoboCell is a fully integrated robotic automation system engineered for a wide range of industrial applications and educational training environments. Built on a robust aluminum extrusion frame, it combines precision engineering, modular flexibility, and real-world industrial relevance. This advanced platform is designed to optimize key operations including material handling, assembly, inspection, and automated sorting. It integrates seamlessly with multiple smart modules tailored for specific tasks such as tool changing, vision-based part assembly, RFID-based traceability, weight classification, and color-based sorting. Driven by a combination of robotics, vision systems, sensor technology, and PLC integration, the Handling RoboCell delivers exceptional flexibility, accuracy, and responsiveness making it an ideal solution for smart manufacturing environments and Industry 4.0 implementation. 🔹 Key Features ▪ 6-Axis Industrial Robot with multi-tool handling ▪ Tool changer station for flexible operations ▪ Industry 4.0/IIOT applications ▪ Vision system for shape-based inspection ▪ RFID-enabled traceability and sorting ▪ Color and weight-based sorting modules ▪ PLC (Siemens/Mitsubishi) with remote HMI & IIoT ▪ Smart pneumatic fixtures with magnetic locking ▪ IO-Link sensor integration for advanced diagnostics ▪ Modular conveyor with auto-load capability ▪ Completely integrated with Digital Twin with offline programming ▪ Visual alerts via lamp ▪ Durable, compact aluminium frame design

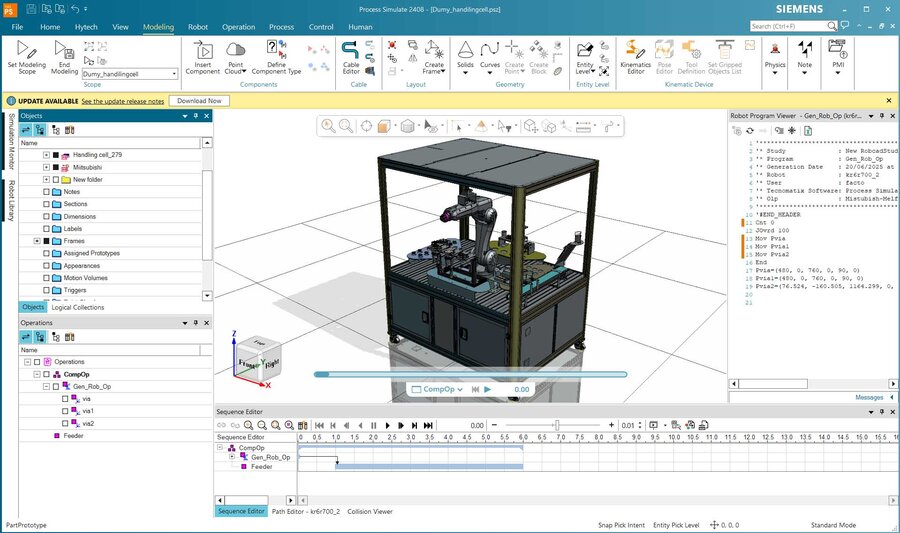

Structure Structure made in Aluminium Extrusions Outer Dimensions: 1700 x 1300 x 1900 (Ht) 4 Castor Wheels with Brakes and anti-vibration mounts Complete transparent enclosure with 4 doors and door latching switches Horizontal worksurface made in Aluminium Extrusions Robot / Cobot Pedestal made in Mild Steel with mounting arrangements Robot Controller arrangement with electrical control panel for Robot Operations Transparent door with door latching switch for Robot Controller ROBOT KUKA / FANUC / Mitsubishi ROBOT with Teach Pendant Minimum Payload: 7 KG Minimum Reach: 700mm Pneumatic Gripper (Parallel) with minimum 7 KG Payload Capacity and minimum opening of 20mm Digital Twin Integration Provision of complete setup in STP format for offline programming Complete integration with Siemens Tecnomatix and Visual Components for Offline Robot Programming Central Control Unit Separate Structure made in Aluminium Extrusions with top surface of 720mm x 1000mm Top surface made partially in Aluminium extrusions and partially in MDF 4 Castor Wheels with Brakes and anti-vibration mounts Complete Electrical panel with PLC Transparent doors on front side with door latching switch Aluminium extrusion-based mounting arrangement for LED TV, LED Monitor and HMI Siemens S7 1200 / Mitsubishi FX 5 PLC Siemens MTP 700 HMI / Mitsubishi GT 2110 HMI Siemens TIA License (Latest Version - Perpetual) IIOT - Siemens Industrial Edge (Optional) I/O Link Master with minimum 8 Ports I/O Link based Smart Light HMI Mounting unit with push buttons for CYCLE START, CYCLE RESET, EMERGENCY STOP Workstation (Intel i5) with 21 inch monitor preconfigured with the system / High Performance Laptop preconfigured with the system Wireless Keyboard and Mouse Table 1 – Conveyor with RFID Based Sorting Conveyor with DC Geared Motor and Pneumatically actuated Auto Feeder Minimum travel length: 500mm Minimum width: 70mm I/O Link based RFID Reader and Writer RFID Tags (8 Qty) Workpieces with mounting arrangement for RFID Tags (Qty: 08) Pallet for workpieces Table 2 – Load Based Sorting and Colour Based Sorting I/O Link based Colour Sensor Load Cell with Analog Output and Digital Set Point Workpieces in 3 different colours for colour-based sorting (Qty: 06) Workpieces in 3 different weights for load-based sorting (Qty: 06) Pallet for workpieces Table 3 – Vision Based Sorting and Assembly Vision Cameras (Cognex) with Profinet Communication Pneumatic Guided Cylinder for Workpiece Clamping Workpieces in different shapes (Qty: 06) Pallet for workpieces Table 4 – Robot Tool Changer Robot Side Tool (1 Qty) Tool Side Clamping (Qty: 03) Vacuum Gripper with Vacuum Generator Pneumatic Parallel Gripper Mounting arrangement for grippers made in Aluminium Extrusions Digital Twin Software – Optional (Option 1) Siemens Tecnomatix (1 Seat) – 1 Year Subscription-Based License (License will deactivate after 1 year) Digital Twin Software – Optional (Option 2) Visual Components (15 Seats) – Perpetual License with 1 Year AMC (License will be active permanently but updates will be available only for 1 year)

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review