IIOT Based Smart Factory Setup with Industrial Robot (Smart Factory)

PL-988015

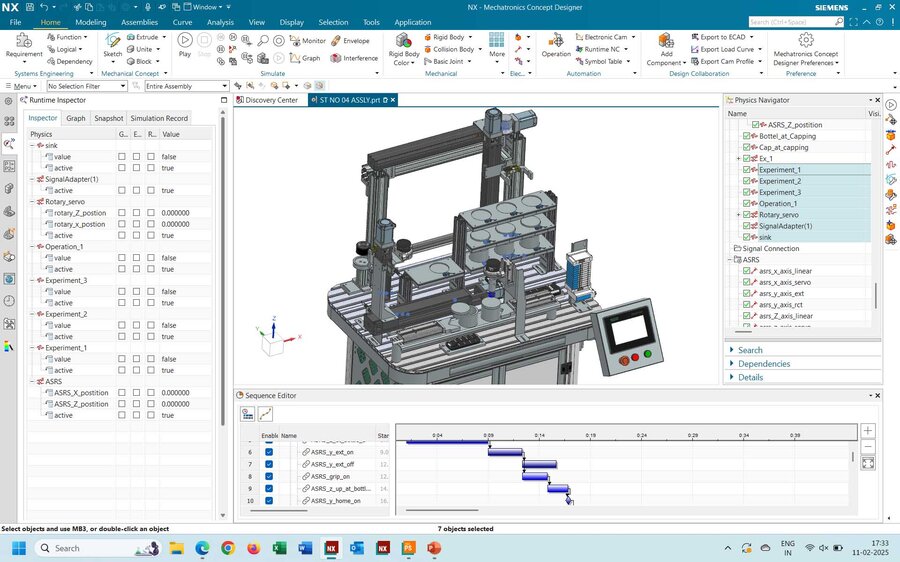

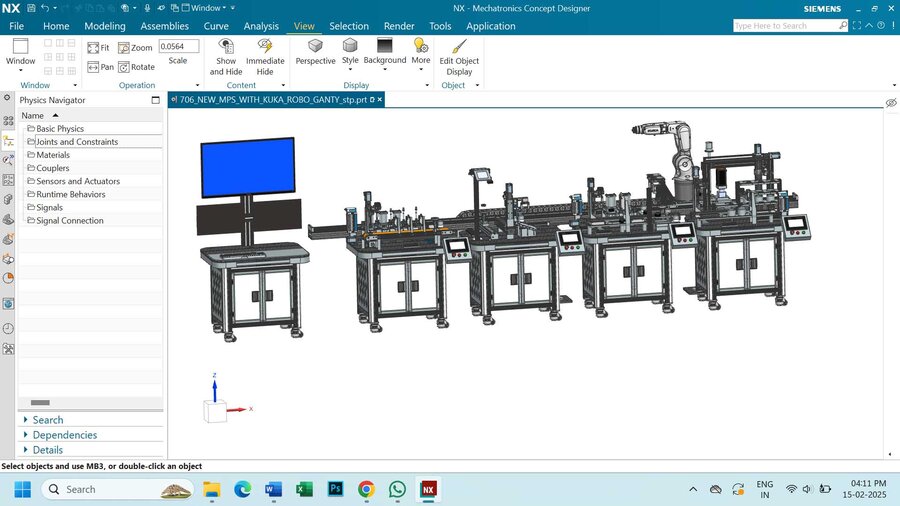

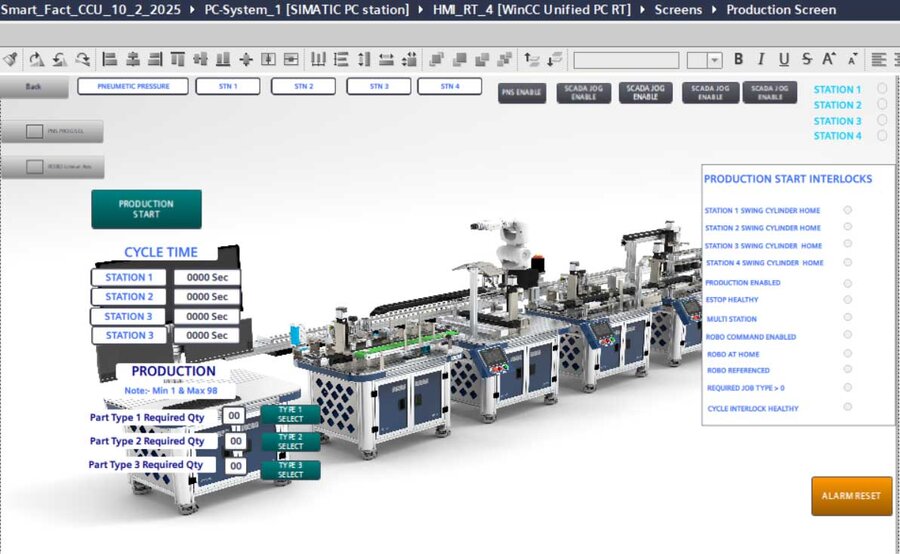

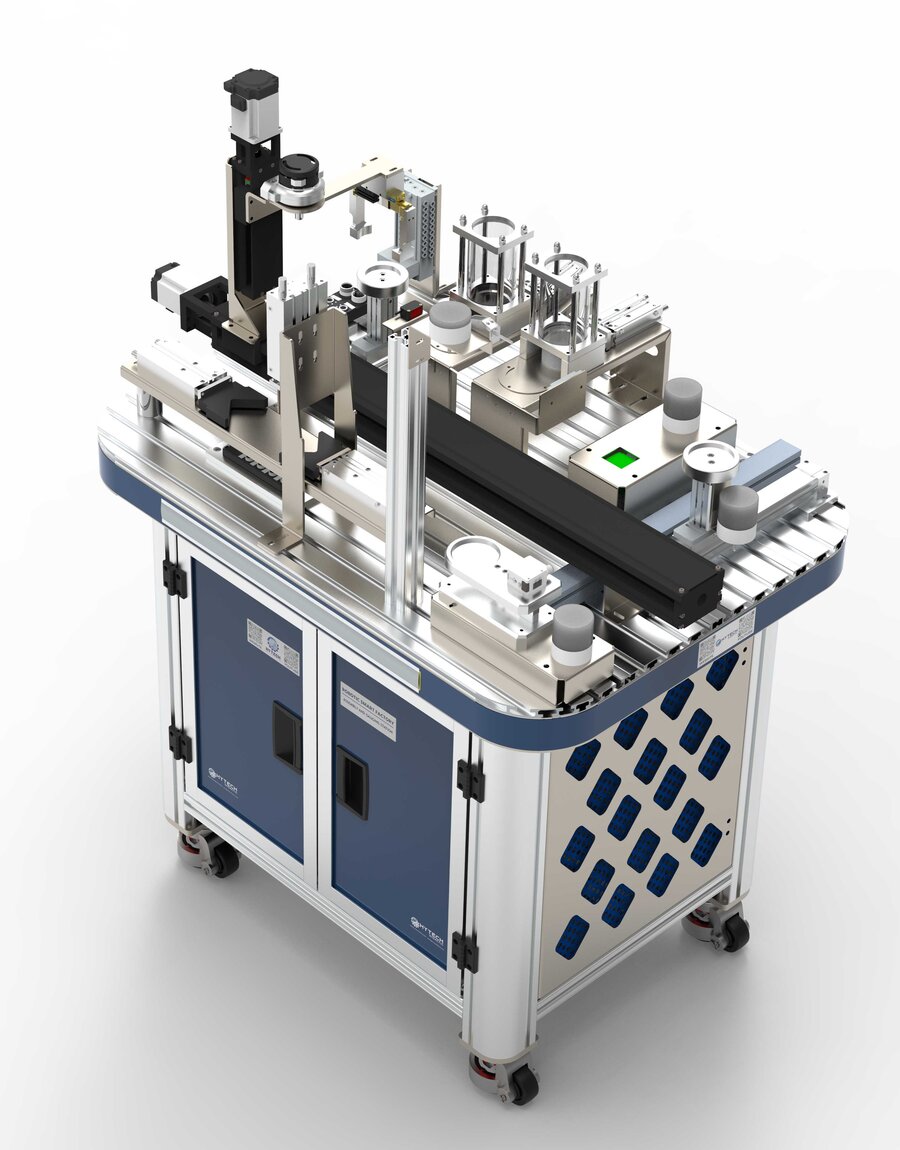

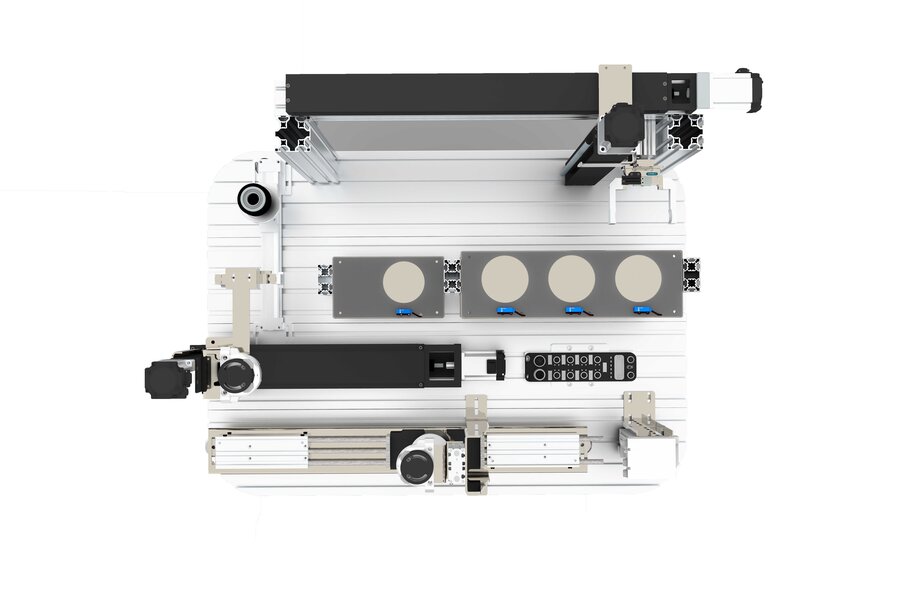

# Robotic Smart Factory with 7-Axis Robot & Digital Twin The Robotic Smart Factory is an Industry 4.0–ready training and demonstration system that replicates real-world smart manufacturing environments. Built with industrial-grade components, it offers hands-on experience in automation, robotics, and digital manufacturing workflows. # Seamless Industrial Integration The system integrates PLC, HMI, SCADA, and IIoT Edge technologies to deliver a complete smart factory experience. Key features include: * IO-Link–based device communication for modular expansion * RFID-based part tracking and real-time sensor data logging * End-to-end process visibility and intelligent decision-making # Advanced Automation Stations Each station performs a dedicated industrial function using real-world components: * Pneumatic Gauging: Precision diameter measurement with automated rejection * Vision Inspection: Smart camera–based defect detection and sorting * Assembly Station: Weight measurement, color sensing, and level detection * ASRS Handling: Automated storage, vacuum-based capping, and pick-and-place These stations enable learners to understand complete production workflows from inspection to handling. # Gantry-Mounted 7th Axis Robot A high-precision robot mounted on a gantry-based 7th axis enables inter-station material handling. An automatic tool changer allows seamless switching between grippers and tools based on process requirements. # Digital Twin & Virtual Programming Integrated digital twin software enables real-time simulation, safe virtual testing, and multi-user training. Offline programming tools support robot path planning and PLC/HMI logic validation, reducing commissioning time and hardware risk. # Rugged Modular Design * Industrial aluminum extrusion framework * Transparent polycarbonate safety enclosures * Anti-static work surfaces and robust mounting * Lockable castor wheels for mobility and stability # Centralized Control & Workstation A centralized control panel includes an industrial PLC, touch-based HMI, and SCADA monitoring. The operator workstation is pre-installed with software for digital twin operation, offline programming, and real-time process monitoring.

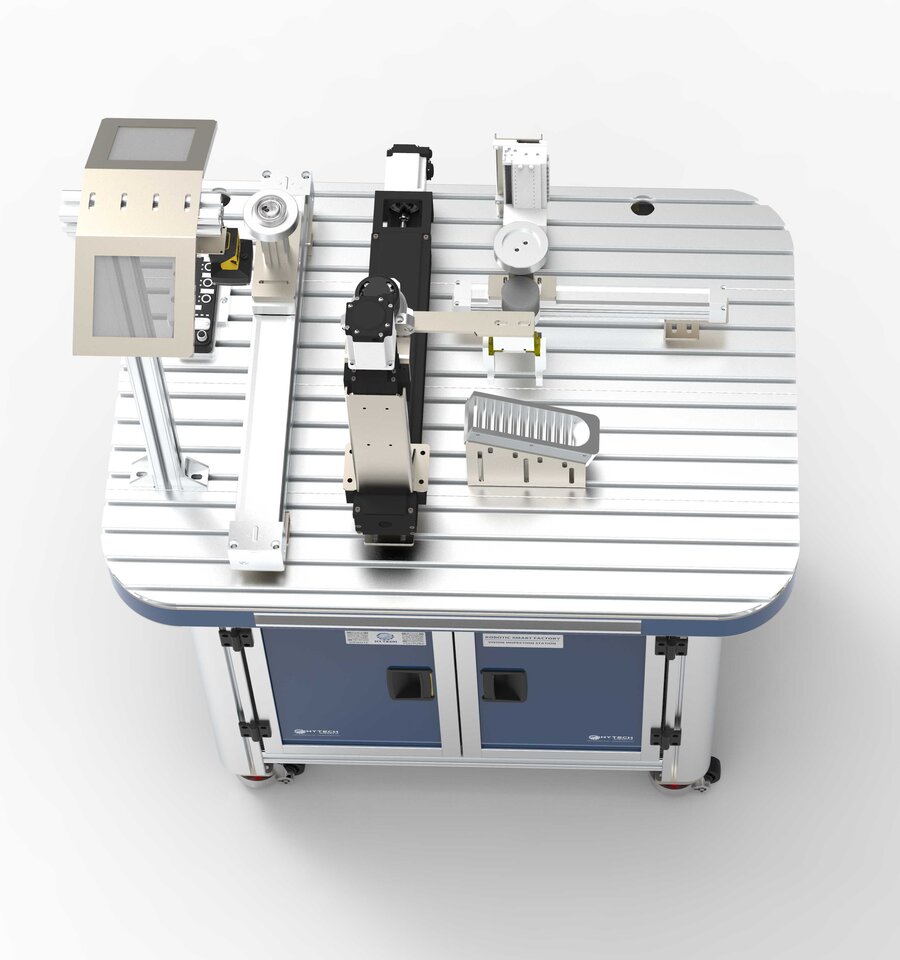

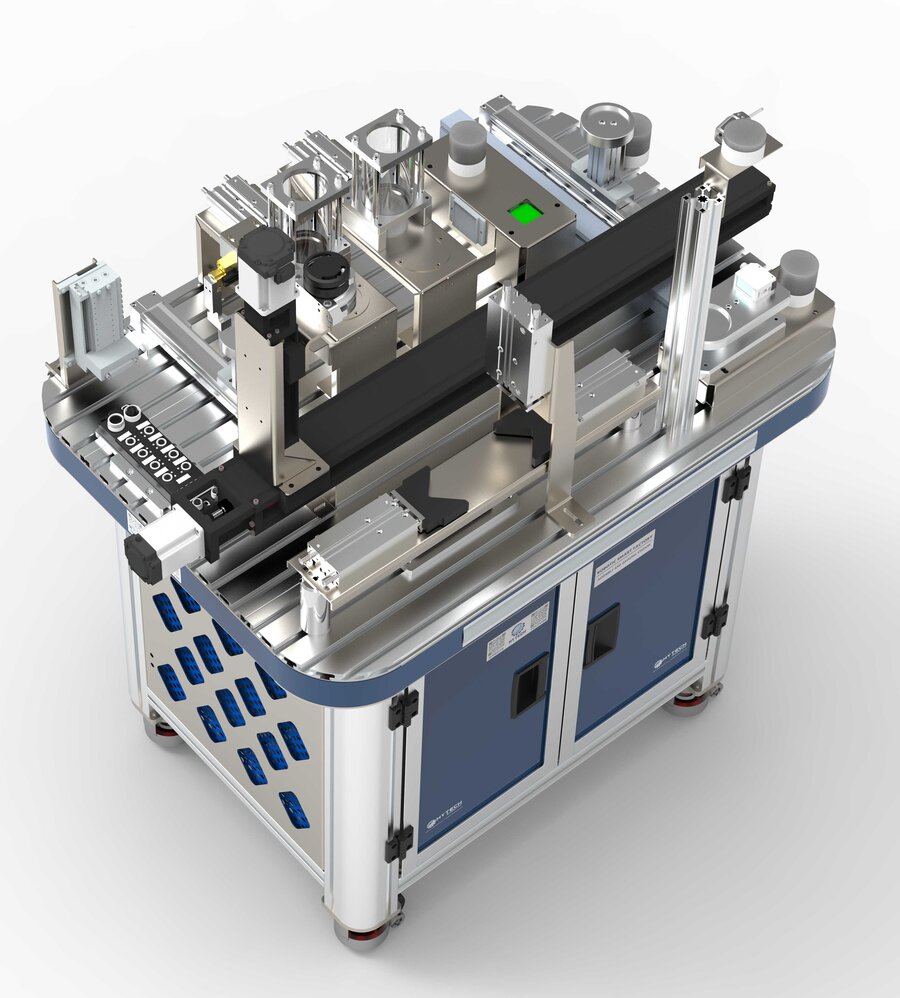

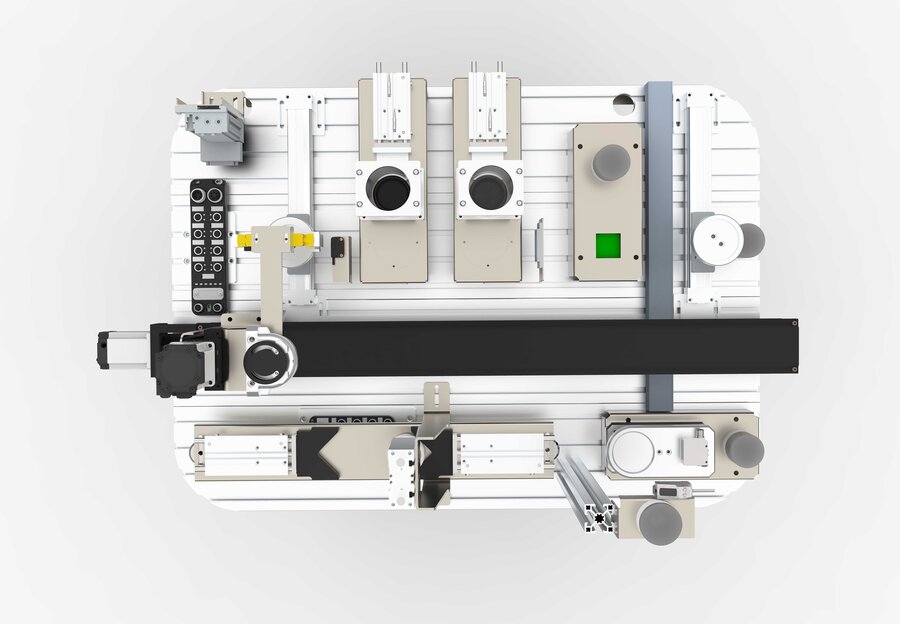

Industrial Robot with Automatic Tool Changer Flexible Automation for Multi-Tasking Operations The Industrial Robot with Automatic Tool Changer is a high-performance robotic system designed to perform multiple operations by automatically switching between end-effectors. It enhances flexibility, efficiency, and adaptability in modern manufacturing and training environments. Key Features: Automatic tool changing for grippers, vacuum cups, and custom tools High-precision multi-axis robotic arm Compact tool storage rack PLC and HMI integration for real-time control and monitoring Integrated sensors and industrial safety features Station 1: Bearing Dispensing & Pneumatic Gauging This station sorts three bearing types with identical outer diameters but different inner diameters using a pneumatic gauging system. Non-conforming bearings are automatically rejected. Learning Outcomes: PLC–HMI integration Sensor and reed switch integration Sequential PLC programming Pneumatic and servo system control Quality-based sorting logic PLC, SCADA, and robot integration Station 2: Vision Inspection A smart vision camera inspects bearings based on taught parameters. Accepted bearings are sorted, while rejected parts are sent to a separate bin. Learning Outcomes: PLC and vision system integration Vision camera teaching Servo and pneumatic motion control Rodless cylinder applications Robot integration with PLC and SCADA Station 3: Assembly & Gauging Bearing housings are inspected using weight, color, and level sensors before and after assembly. Product data is written to an RFID system for tracking and then transferred for packaging. Learning Outcomes: Sensor operation (weight, color, level) RFID read/write operations PLC–HMI integration Real-time data tracking PLC, SCADA, and robot integration Station 4: Packaging & Storage (ASRS) An ASRS Cartesian robot retrieves containers and caps. A servo-driven pick-and-place system transfers them to a vacuum-based capping module before returning finished products to storage. Learning Outcomes: PLC and HMI integration Servo teaching and positioning Pneumatic gripper and rotary operations ASRS applications Central Control with PLC, HMI & IIoT: A dedicated Central Control Unit (CCU) integrates PLC and HMI to control all stations, robots, and the 7th-axis gantry. Users can create custom PLC programs and HMI screens while integrating RFID, IO-Link sensors, servos, and pneumatic systems. IIoT Integration The system uses Siemens Industrial Edge for: Real-time data acquisition Edge-to-cloud connectivity Remote monitoring and analytics All required PLC, HMI, SCADA, and Industrial Edge licenses are pre-installed. Learning Outcomes: CCU architecture and control 7th-axis robot integration SCADA design Digital twin integration via OPC UA End-to-end smart factory operation Gantry-Mounted Robot with Tool Changer A robot mounted on a servo-driven 7th-axis gantry enables smooth material handling across all stations. The automatic tool changer supports pneumatic grippers, vacuum tools, and custom end-effectors, reducing cycle time and eliminating manual tool changes. All operations are controlled and monitored via PLC, HMI, and SCADA. Robotic Smart Factory with IIoT & LMS The Smart Factory integrates Industrial IoT technologies to enable data-driven manufacturing and remote monitoring using protocols such as MQTT and OPC UA. The system includes a Learning Management System (LMS) offering: Step-by-step guided training Continuously updated content Custom course creation, assessments, and certifications This solution prepares learners and trainers for Industry 4.0 roles in smart manufacturing environments.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review