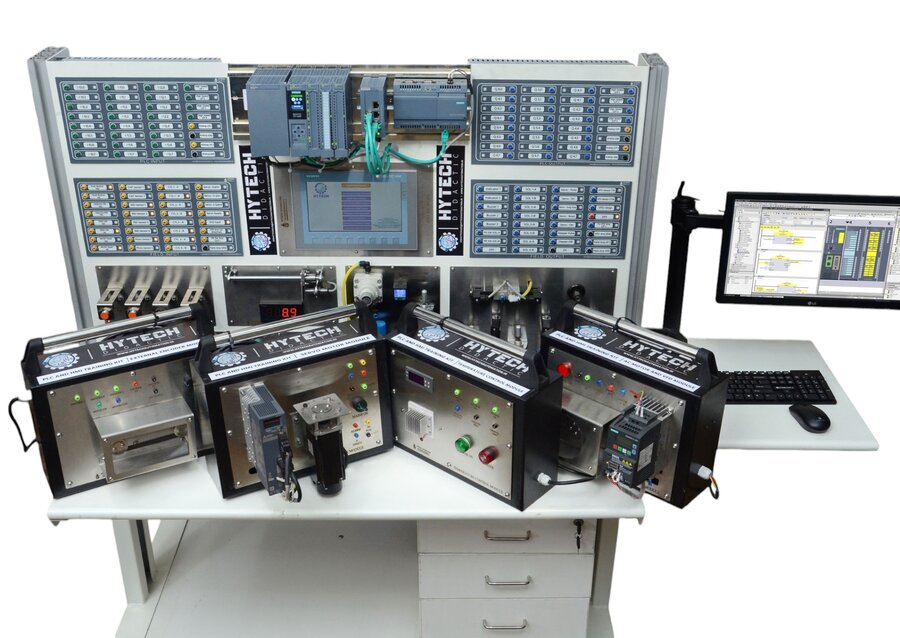

PLC Training Kit - Advanced (PH - Advanced)

PL-190281

Hytech Didactics’ PLC and HMI Training kit is ergonomically designed to provide detailed training on latest industrial PLCs and HMIs.

Important advantage of Hytech training kit is that it can be equipped with any make or model of PLC and HMI.

Specially designed input and output modules are provided with necessary safety arrangements to avoid damage to PLC or HMI during operation by inexperienced users or students.

Input and Output modules allow users to connect the relevant field component with specified PLC input or output with the help of patch chords.

This makes the whole system flexible providing necessary ease of operation.

Outer Dimensions without Workstation:

- Length 1200mm

- Depth 800mm

- Height 1600mm

Outer Dimensions with Workstation:

- Length 1600mm

- Depth 800mm

- Height 1600mm

The PLC and HMI Training kit is provided with Castor wheels and mounting arrangement.

The kit is a completely mobile unit which can be mounted on a rigid base when required.

The structure is made in powder coated mild steel providing it with necessary strength.

Top, bottom and a 4 drawer pedestal are provided in industrial MDF which are bolted to the structure.

Ergonomic arrangement for workstation mounting is provided with monitor mounting stand.

Connector based wiring makes the wiring easily understandable to users.

The Hytech PLC and HMI Training kits is equipped with real time industrial automation components providing much needed exposure to participants on latest industrial technologies.

Participants can integrate various modules with PLC, HMI and workstation to operate them as per the requirement.

List of Industrial Automation Modules: Sensor Module - Digital Sensor Module - Analogue Switchgear Module Pneumatic Operation with Solenoid valves and Cylinders Stepper Motor Module Servo Motor Module AC Motor and Encoder Pneumatic Pressure Switch Application (Analog Control) AC Motor Speed Control through VFD and PLC using HMI Temperature Control Module (Analog Control) Conveyor Control Module Load Cell with Digital Display Module (Analog Control) Flow Sensor Module (Analog Control) Static automation modules are provided where participants can carry out predefined industrial process.

These static modules can be integrated with PLC, HMI and workstation with patch cords.

List of Static Automation Modules: Traffic Control Module Elevator Module Water Level Control Module Staircase Lighting Module Conveyor Module AC Motor - Star Delta Connection Module

Hytech PLC and HMI Training Kits (Siemens) Sr No Description Qty Make 1 Floor Mounted PLC Training Kit Structure (PH Advance) (PH Advance: 1.1 PLC Workstation with floor mounted kit and MDF top.

1 NA MDF Table Dimensions: 1200mm x 800mm x 25mm(Thickness) Four Castor wheels with brake and an arrangement for LCD monitor mounting. Pedestal with 4 drawers in MDF with minimum total dimension of (wd-400mm x D-450mm x Ht-550mm)

2 Workstation Module

- 2.1 Computer station with minimum specifications of: Intel i3 5th Generation Processor, Monitor of 19", Bluetooth Keyboard and Mouse, 500GB Hard Disk, 8 GB RAM, Windows 10 1 HP / DELL / ACER

- 2.2 CPU Holding stand 1 NA

- 2.3 Monitor Stand 1 NA 2.4 MDF Panel for Keyboard and Mouse Operation 1 NA 2.5 Siemens Profinet cable for PC to Scalance communication 1 Siemens

3 Siemens S7 1200 PLC Module

- 3.1 Siemens S7 1200 - 1215C 1 Siemens

- 3.2 Siemens TIA (Basic) Perpetual License (STEP 7 Basic V15 Floating License) 1 Siemens

- 3.3 24V 5A Power Supply 1 Siemens

- 3.4 Power supply and control panel for PLC 1 Reputed Make

- 3.5 PLC Input module with input override switches (24 inputs) 1 HYTECH

- 3.6 Field input module (24 inputs) 1 HYTECH

- 3.7 PLC output module (24 outputs) 1 HYTECH

- 3.8 Field output module (24 outputs) 1 HYTECH

- 3.9 2mm Patch cord connector set 1 set NA

4 Siemens S7 1500 PLC Module:

- 4.1 CPU 1512C-1 PN Consisting of: S7-1500 CPU 1512C-1 PN, 250 KB/1 MB, 32 DI, 32 DQ, 5 AI, 2 AQ, SIMATIC Memory Card 24 MB, incl. front connector, Ethernet cable RJ45/RJ45 6 m, PM 1507 Mounting rail, 482 mm, Software for training STEP 7 1 Siemens

- 4.2 STEP 7 Software (Perpetual) floating license for S7 15000 PLC 2 Siemens

- 4.3 KTP900 Basic - HMI 1 Siemens

- 4.4 SCALANCE XB005 - 5 Port Siemens Scalance Router 1 Siemens

- 4.5 Lite PSU100L,1 phase, 24VDC/10A 1 Siemens

- 4.6 Power supply and control panel for PLC 1 Reputed Make

- 4.7 PLC Input module with input override switches (24 inputs) 1 HYTECH

- 4.8 Field input module (24 inputs) 1 HYTECH

- 4.9 PLC output module (24 outputs) 1 HYTECH

- 4.10 Field output module (24 outputs) 1 HYTECH

- 4.11 2mm Patch cord connector set 1 set NA

5 HMI Module (Siemens KTP 700)

- 5.1 KTP 700 Basic HMI 1 Siemens

- 5.2 Siemens TIA (Basic) Perpetual License (STEP 7 Basic V15 Floating License) 1 Siemens

6 HMI Module (Siemens KTP 900)

- 6.1 KTP 900 Basic HMI 1 Siemens

- 6.2 Siemens TIA (Basic) Perpetual License (STEP 7 Basic V15 Floating License) 1 Siemens

7 Switch Module (Unmanaged)

- 7.1 SCALANCE XB005 - 5 Port Siemens Scalance Router 1 Siemens

- 7.2 Profinet cable for PLC to Scalance communication 1 Siemens

- 7.3 Profinet cable for HMI to Scalance communication 1 Siemens

8 IIOT / Industry 4.0 Platform

- 8.1 Siemens Industry 4.0 Hardware with profinet communication 1 Siemens

- 8.2 Router with minimum 30 meter coverage for localised IIR access 1 Siemens

- 8.3 Class 10 Memory Card - Minimum 8 GB 1 Siemens

- 8.4 7 meter profinet Cable (Make: Siemens) 1 Siemens

9 Sensor Module (Digital)

- 9.1 Capacitive Sensor (PNP, NO Type) 1 Contrinex / Omron

- 9.2 Photo Sensor (PNP, NO Type) 1 Contrinex / Omron

- 9.3 Proximity Sensor (PNP, NO Type) 1 Contrinex / Omron

- 9.4 Proximity Sensor (PNP, NC Type) 1 Contrinex / Omron

10 Sensor Module (Analog)

- 10.1 Analog Inductive Sensor M18 1 Contrinex / Omron

- 10.2 Analog Ultrasonic Sensor 1 Contrinex / Omron

- 10.3 Analog Inductive Sensor M12 1 Contrinex / Omron

- 10.4 Ultrasonic Distance Measurement Sensor with Display 1 Contrinex / Omron

- 10.5 Analog Power Supply with Digital Display 1 HYTECH / Omron

- 10.6 Sensing Unit 1 HYTECH

11 Switchgear Module

- 11.1 Push Button (NO Type) 2 Schneider / Siemens

- 11.2 Push Button (NC Type) 2 Schneider / Siemens

- 11.3 Selector Switch (NO Type) 1 Schneider / Siemens

- 11.4 Selector Switch (NC Type) 1 Schneider / Siemens

- 11.5 Emergency Switch (Mushroom Head) 1 Schneider / Siemens

- 11.6 Mushroom Head Push Button (For Both Hand Operation) 1 Schneider / Siemens

- 11.7 Indicators (Red and Green) 2 Reputed Make 11.8 Buzzers 2 Reputed Make

12 Automation Module: Pneumatic Operation with Solenoid valves and Cylinders

- 12.1 Double Acting Solenoid Valve 3 SMC / Festo

- 12.2 Single Acting Solenoid Valve 1 SMC / Festo

- 12.3 Double Acting Pneumatic Cylinder (Stroke: 30mm) 3 SMC / Festo

- 12.4 Pneumatic Motor 1 Reputed Make

- 12.5 Hand slide valve for Pneumatic connection 1 Reputed Make

- 12.6 Pneumatic Junction box (5 Port) 1 SMC / Festo

- 12.7 Pneumatic Pushpull connectors for pneumatic components 1 set Reputed Make

13 Automation Module: Stepper Motor Module

- 13.1 Stepper Motor (10 Kg cm) with 230V Single Phase Power Supply 1 Leadshine / Reputed

- 13.2 Stepper Drive of suitable capacity 1 Leadshine / Reputed

- 13.3 Necessary Cables 1 Set Lapp

- 13.4 Necessary Power Supply for Stepper Motor and Stepper Drive 1 Set Omron / Siemens / NHP

14 Automation Module: Servo Motor Module

- 14.1 Siemens Servo Motor (400 W) with 230V Single Phase Power Supply 1 Siemens

- 14.2 Siemens Servo Drive (400 W) 1 Siemens

- 14.3 Necessary Power and Encoder Cables 1 Set Siemens

15 Automation Module: DC Motor and Encoder

- 15.1 DC Motor (24V DC Supply) 1 Panasonic

- 15.2 Gearbox for DC Motor 1 Panasonic

- 15.3 Encoder (350 PPR) 1 Delta / Kuebler

- 15.4 DC Motor speed controller 1 Set Lapp

- 15.5 Necessary Cable for Encoder 1 Set Lapp

16 Automation Module: Pneumatic Pressure Switch Application (Analog Control)

- 16.1 Pneumatic Pressure Switch with digital display and analog output 1 SMC / Festo

- 16.2 5/3 Way hand lever operated pneumatic valve 1 SMC / Festo

- 16.3 5/2 way double acting solenoid valve 1 SMC / Festo

- 16.4 Double acting cylinder with reed switches 1 SMC / Festo

17 Automation Module: AC Motor Speed Control through VFD and PLC using HMI

- 17.1 G120C with Profinet (0.55 KW) 1 Siemens

- 17.2 AC Induction Motor (0.5 KW) 1 Siemens / Equivalent

18 Automation Module: Temperature Control Module (Analog Control)

- 18.1 Heater Module 1 Reputed Make

- 18.2 Blower / Fan 1 Reputed Make

- 18.3 Temperature indicator (Digital) 1 Reputed Make

- 18.4 Buzzer 1 Reputed Make

- 18.5 Thermocouple / RTD 1 Reputed Make

- 18.6 12V SMPS (5A) 1 Siemens / NHP

- 18.7 Relay Module (2 Channel) 1 Reputed Make

19 Automation Module: Conveyor Control Module

- 19.1 Conveyor 70 x 500mm (AC Motor driven with gear box) 1 HYTECH

- 19.2 Rotary Rejection Module Mount 1 NA

- 19.3 Rotary Vane Motor 2 Festo / SMC

- 19.4 Rejection Bin 2 NA

- 19.5 Sensor Mounting Bracket (Conveyor) M18 3 NA

- 19.7 M18 Inductive Sensor 1 Omron / Contrinex

- 19.8 M18 Photoelectric Sensor 2 Omron / Contrinex

20 Automation Module: Load Cell with Digital Display Module (Analog Control)

- 20.1 Holding station with mounting arrangement for load cell 1 NA

- 20.4 Load Cell (Capacity: Up to 10 KG) 1 Reputed Make

- 20.5 Load Cell Amplifier with analog output 1 Reputed Make

21 Automation Module: Flow Sensor Module (Analog Control)

- 21.1 Pneumatic Flow Switch with digital display and analog output 1 SMC / Festo

- 21.2 5/3 Way hand lever operated pneumatic valve 1 SMC / Festo

- 21.3 5/2 way double acting solenoid valve 1 SMC / Festo

- 21.4 Double acting cylinder with reed switches 1 SMC / Festo

22 Static Automation Modules

- 22.1 Traffic Control Module 1 HYTECH

- 22.2 Elevator Module 1 HYTECH

- 22.3 Water Level Control Module 1 HYTECH

- 22.4 Staircase Lighting Module 1 HYTECH

- 22.5 Conveyor Module 1 HYTECH

- 22.6 AC Motor - Star Delta Connection Module 1 HYTECH

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review