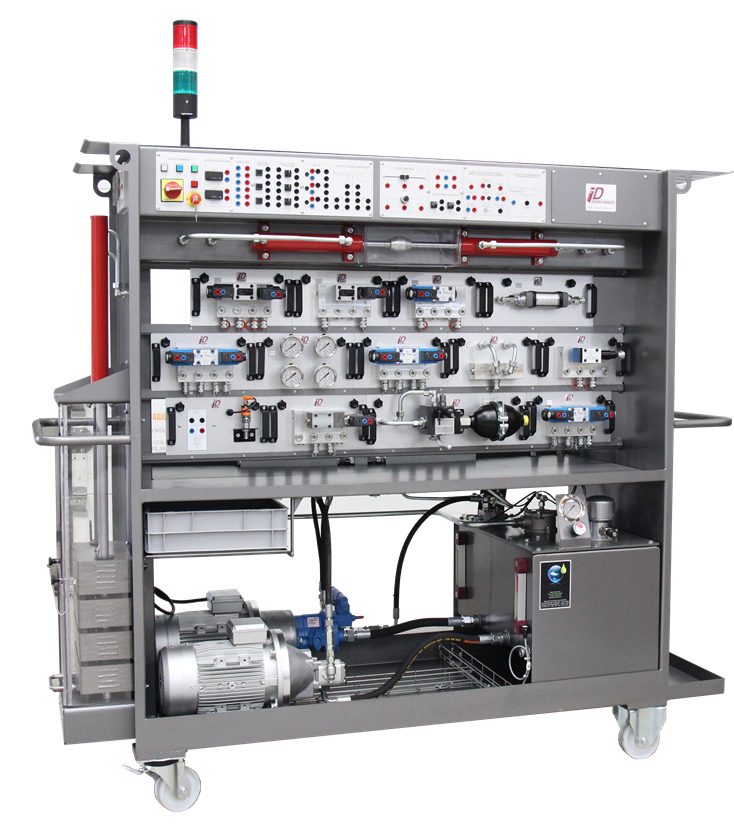

Hydraulic Training Bench BHI4 (BHI4)

PL-357783

Choose the industrial components so that your students can perform different exercises. They will thus be able to understand the hydraulic functions and to achieve different wiring circuits.

Completely modular and upgradeable system

The hydraulic didactic training bench BHI4 is a completely upgradeable and modular fitting system.

Its robust steel mechanical soldered chassis, single or double face, is designed to allow industrial components mounted on anodized plates.

Equipped with hoses with quick couplings, this bench allows for wiring circuits in on-off and proportional hydraulics.

With over 60 available components modules in the catalogue, we are be able to offer 5 packs intended for different training levels.

- BHI4 V1 – ON OFF Manual (Single Face Bench – On-Off)

- BHI4 V2 – ON OFF Elec (Single Face Bench – On-Off)

- BHI4 V3 – PROPORTIONAL (Single Face Bench – Proportional)

- BHI4 V4 – ON OFF & PROPORTIONAL (Double Face Bench – On-Off & Proportional)

- BHI4 V5 – MOBILE (Single Face Bench – Mobile)

Details of the BHI4 hydraulic didactic bench

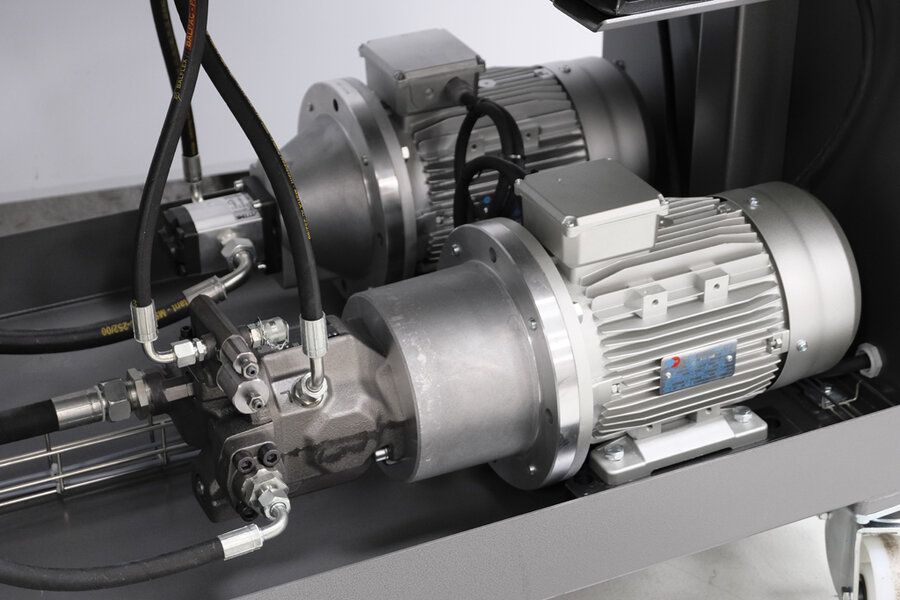

- Hydraulic power station with fixed or variable displacement with LS,

- Hydraulic components mounted on a drilled aluminium block with built-in pressure taps,

- Hoses equipped with 3/8″ flat face clean couplers,

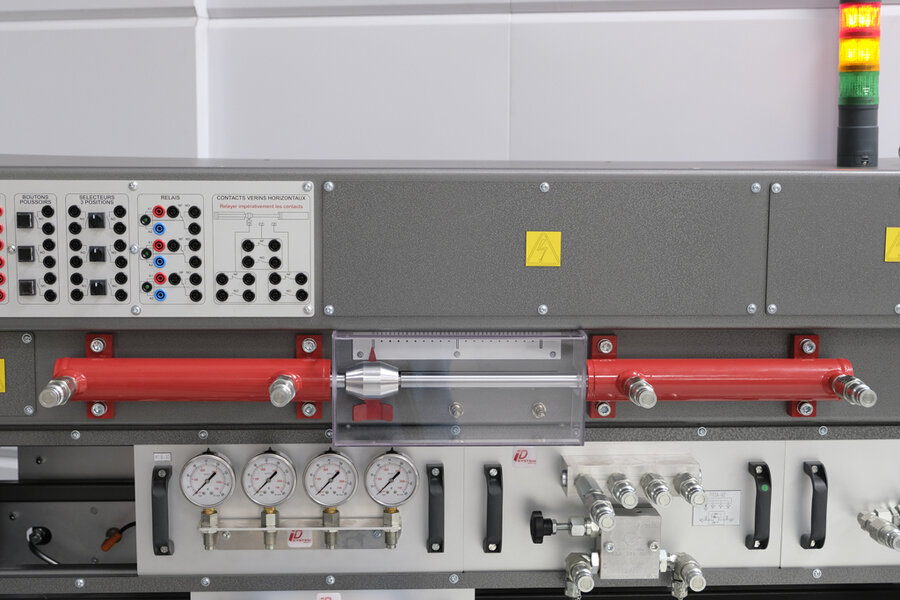

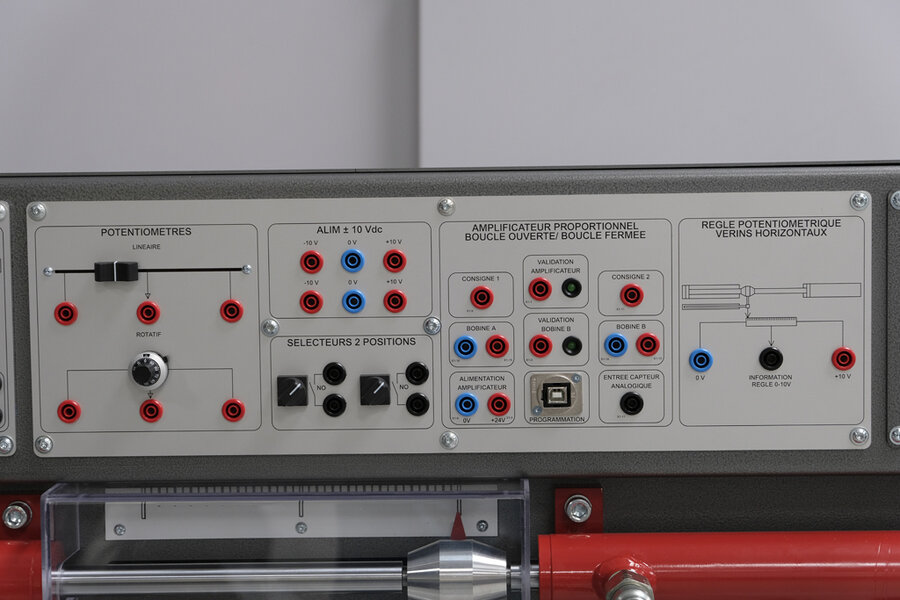

- Electrical racks with On/Off and proportional controls

- Vertical cylinder with modular suspended load,

- Storage module,

- PID regulation card configuration software – Open Loop or servo system,

- Antagonistic horizontal cylinders with position sensors.

Detail of the educational file that we have broken down into 3 levels:

A) Level 1

Practice on ON OFF face

- PW1: The hydraulic unit

- PW2: The pressure relief valve

- PW3: The TOR distributor

- PW4: The flow relief valve

- PW5: The double-acting cylinder

- PW6: Load lifting

- PW7: Check valve and balancing valve

- PW8: Pressure reducer

- PW9: Sequence valve

- PW10: The accumulator

B) Level 2

Practice on the “PRO OL / CL“ side

- PW1: Increase the speed of a cylinder by differential overcharging

- PW2: Decompress a volume of pressurized oil in a cylinder and elastic pipes

- PW3: Select 2 pressure levels in one hydraulic circuit

- PW4: Conditioned sequence of movement of 2 jacks

- PW5: Using an energy reserve

- PW6: Adjusting a speed

- PW7: Managing a constant flow

- PW1p: The proportional valve in open loop

C) Level 3

Practice on the “PRO OL / CL“ side

- PW1: Load Sensing

- PW 1p: The proportional pressure relief valve

- PW 2p: The proportional flow relief valve

- PW 3p: Position control on a cylinder

- PW 4p: Speed control on a motor

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review