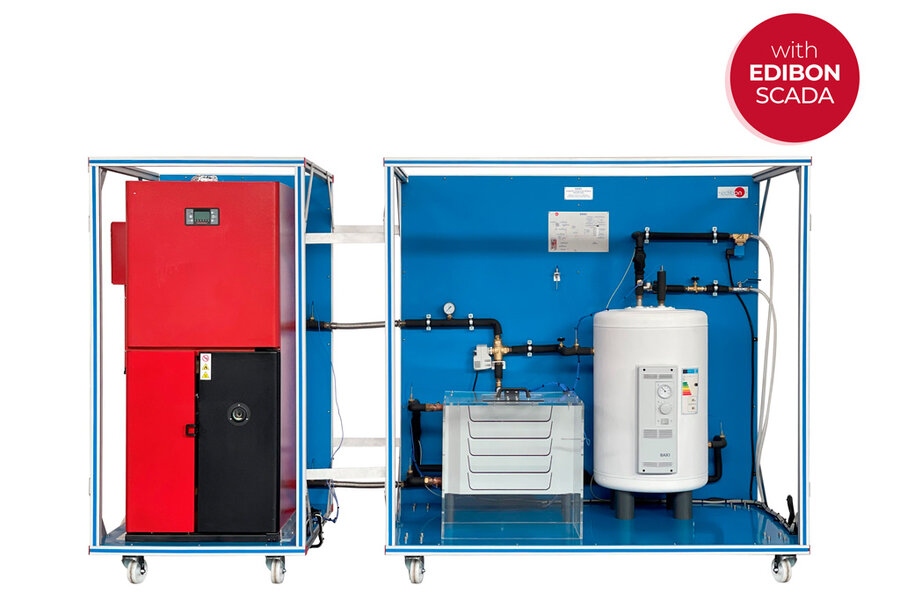

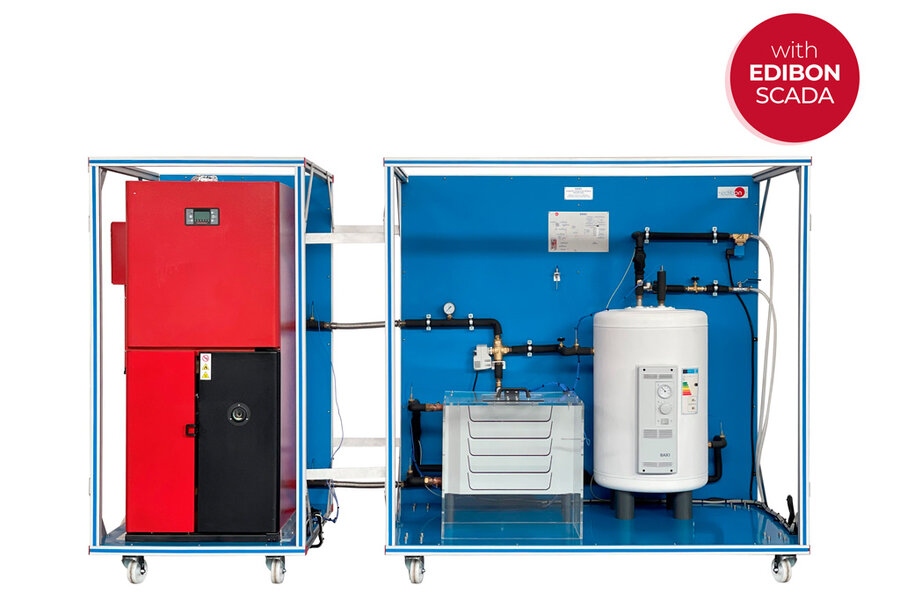

Computer Controlled Biomass Process Unit (EBMC)

PL-634049

The Computer Controlled Biomass Process Unit, "EBMC" designed to heat water, which circulates through connected components to distribute thermal energy. Built with a robust 5 mm-thick steel body, this biomass boiler is compatible with both pellets and other granulated fuels. It features a high-temperature-resistant stainless steel burner with a self-cleaning system, allowing flexibility in fuel types. Additionally, the boiler includes ash extraction compartments and is designed for easy access for maintenance and cleaning.

A computer-regulated circulating pump directs heated water throughout the system. A three-way solenoid valve, also computer-controlled, distributes water between two main circuits: one circuit routes to the double-jacketed storage tank for domestic hot water, while the other leads to a unit heater for space heating. When the valve is active, it allows water flow in both directions; when inactive, it restricts flow to the unit heater, increasing supply to the storage tank.

The 60-liter storage tank is constructed from corrosion-resistant AISI 316 Ti stainless steel and includes a double jacket, through which the heated water circulates as part of the primary circuit. A computer-controlled solenoid valve at the tap water inlet manages flow as needed. The heating unit also features a computer-controlled heater located in a PMMA box, enabling users to monitor and control the heating time required to reach a desired temperature. The heater’s temperature is controlled by a PID system that works in coordination with the three-way solenoid valve.

The primary circuit completes by recycling water from both the storage tank and unit heater circuits, returning it to the boiler. This computer-controlled unit comes equipped with EDIBON’s SCADA system, which includes the main unit, Control Interface Box, Data Acquisition Board, and software packages to manage and monitor the process and all operational parameters.

- EBMC. Unit:

- Anodized aluminum frame and panels of painted steel.

- Main metallic elements of stainless steel.

- Diagram in the front panel with similar distribution to the elements in the real unit.

- This unit includes wheels for its mobility.

- Biomass boiler of 16 kW. It works with pellets and other granulated fuels.

- Double jacket storage tank made of stainless steel of 50 l for the DHW.

- Computer controlled unit heater.

- Box made of PMMA where the unit heater is located. PID control of the box temperature.

- Computer controlled three-ways electronic valve

- Computer controlled solenoid valve located at the storage tank tap water inlet line.

- Three regulation valves of the hot water through the different circuits.

- Manometer, range: 0 - 4 bar.

- Ten “J” type temperature sensors.

- Three water flow sensors, range: 1.5 - 30 l/min.

The complete unit includes as well:

- Advanced Real-Time SCADA and PID Control.

- Open Control + Multicontrol + Real-Time Control.

- Specialized EDIBON Control Software based on LabVIEW.

- National Instruments Data Acquisition board.

- Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

- Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

- Capable of doing applied research, real industrial simulation, training courses, etc.

- Remote operation and control by the user and remote control for EDIBON technical support, are always included.

- Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic and Software).

- Designed and manufactured under several quality standards.

- Optional ICAI software to create, edit and carry out practical exercises, tests, exams, calculations, etc. Apart from monitoring user's knowledge and progress reached.

- This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

- EBMC/CIB. Control Interface Box:

- EBMC/CCSOF. PID Computer Control + Data Acquisition + Data Management Software:

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with 8 manuals: Required Services, Assembly and Installation, Interface and Control Software, Starting-up, Safety, Maintenance, Calibration and Practices Manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Familiarization with the operation of a heating and DHW system with biomass boilers.

- Start-up of a biomass boiler.

- Energy balance in the heating circuit (unit heater) with different types of biomass fuels.

- Energy balance in the sanitary water circuit with different types of biomass fuels.

- Influence of the heating water flow variation in the heat transfer.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review