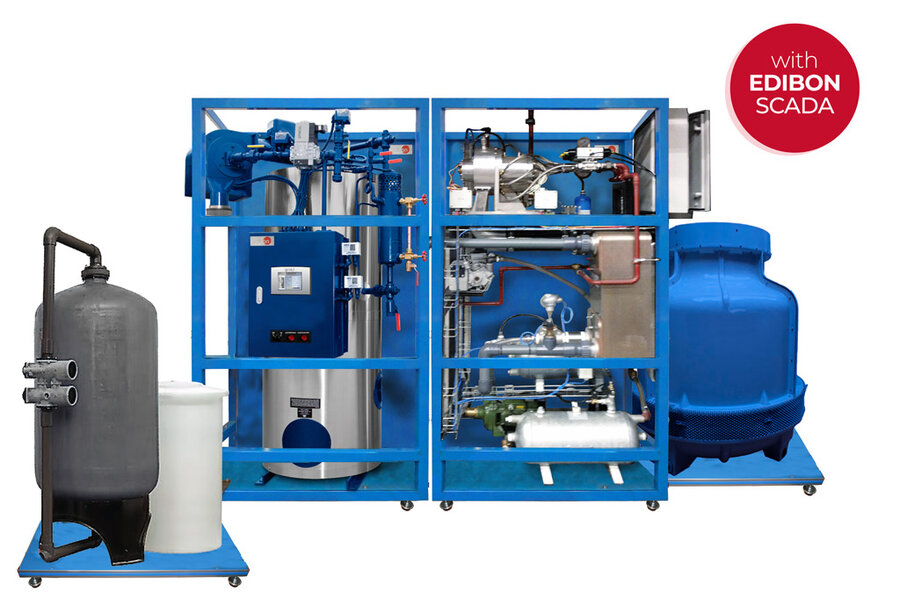

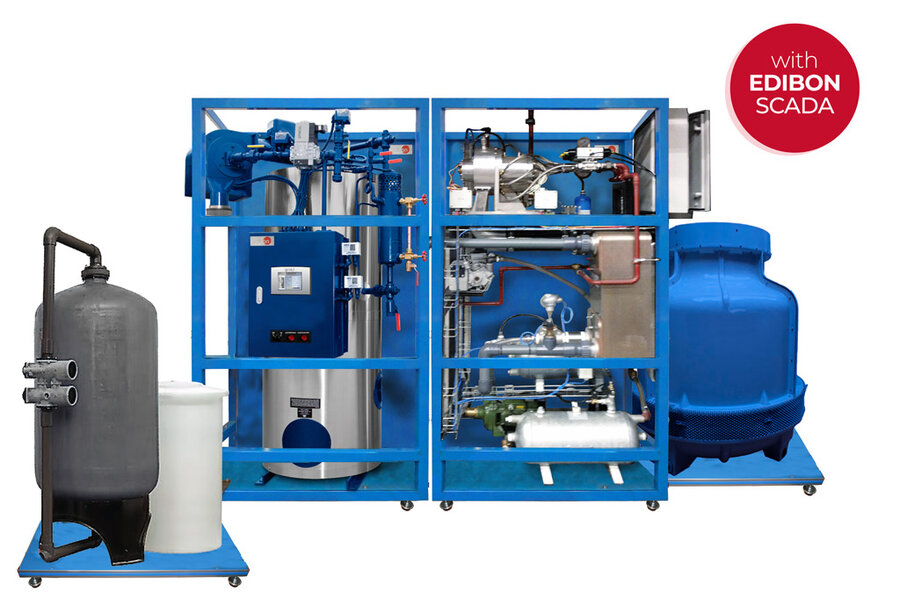

Steam Power Plant Adjustable up to 20 Kw (TPTV/20KW/CTS)

PL-361610

The "TPTV/20kW/CTS" Computer Controlled and Touch Screen 20 kW Steam Power Plant by EDIBON is designed to provide an in-depth study of the power generation cycle using steam. This unit comes with essential supplementary units: the Water Softener (TPTV/20kW-WS), Cooling Tower (TPTV/20kW-CT), and a choice of Water-tube Steam Generator (TPTV/20kW-SGA) or Pirotubular Steam Generator (TPTV/20kW-SGP). Together, these units enhance the plant’s functionality, mirroring the conditions of a full-scale steam power plant.

The Water Softener removes water hardness by using a 40-liter ion exchange resin column that exchanges calcium ions for sodium ions. Decalcified water then flows into the Cooling Tower or the intake tank and, from there, to the Steam Generator. In the Cooling Tower, water is automatically regulated by level switches (AN-6 and AN-7) and valves (AVS-4), and, if necessary, manually emptied through valves V-3 and V-16.

At start-up, the intake tank can be filled with decalcified water or condensed return water. Purge valve V-13 remains open to release air from the tank for smooth filling. If water is absent, valve AVS-3 opens to refill the tank up to level switch AN-5, with manual emptying managed by valves V-9 and V-10.

When the water level is sufficient, it is pumped to the boiler, where it is heated and pressurized through diesel combustion to reach desired steam conditions. The steam then passes through a separator to eliminate suspended droplets and is reheated to become superheated steam. A proportional valve in the system regulates steam flow, allowing broad control over steam rate.

Two steam flow paths are available. One bypasses the turbine through valve AVS-2, leading the steam directly to the condenser to maintain turbine integrity. The other path directs steam through the turbine, where thermal energy is converted into mechanical energy, subsequently transformed into electrical energy by the generator. Sensors monitor the turbine’s rotational speed, torque, and generated power. A lubrication reservoir optimizes turbine rotation, and a drain valve removes condensation from the turbine blades.

This system is fully integrated with EDIBON's SCADA software, allowing comprehensive control over the steam power cycle, including data acquisition and management for a hands-on experience of real-world power plant operations.

- TPTV/20kW/CTS. Unit:

- Anodized aluminum frame and panels made of painted steel.

- The unit includes wheels to facilitate its mobility.

- Main metallic elements made of stainless steel.

- Diagram in the front panel with distribution of the elements similar to the real one.

- Transparent panels to protect the unit that allows the user to observe the operation of the unit.

- Local control of the plant by PLC-HMI system using a 10.1’’ touch screen, allowing users to have an overview of the plant and operating conditions.

- Thermally insulated units and piping with temperatures above 60 °C.

- Intake tank in stainless steel or similar.

- Turbine.

- Condenser.

- Relief valve in the steam generator.

- Float valve.

- Working speed control valve.

- Relief valve in the steam tank.

- Instrumentation

The complete unit includes as well:

- Advanced Real-Time SCADA.

- Open Control + Multicontrol + Real-Time Control.

- Specialized EDIBON Control Software based on LabVIEW.

- National Instruments Data Acquisition board.

- Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

- Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

- Capable of doing applied research, real industrial simulation, training courses, etc.

- Remote operation and control by the user and remote control for EDIBON technical support, are always included.

- Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic and Software).

- Designed and manufactured under several quality standards.

- Optional ICAI software to create, edit and carry out practical exercises, tests, exams, calculations, etc. Apart from monitoring user’s knowledge and progress reached.

- This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

- TPTV/20kW/CTS/CCSOF. PID Computer Control + Data Acquisition + Data Management Software.

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with 7 manuals. Required services, Assembly and Installation and Control software, Starting-up, Safety, Maintenance, Calibration and Practices manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Study, analysis and test of safety systems.

- Study, analysis and test of measurement systems.

- Study, analysis and test of pressure in the circuit.

- Study of the pressure and temperature control techniques in a steam power plant.

- Study, analysis and test of the water softening unit.

- Study, analysis, operation and test of the steam boiler.

- Study, analysis and test of the steam flow sensor.

- Study, analysis and test of the condenser.

- Study, analysis and test of the refrigeration tower.

- Study and analysis of the corresponding maintenance in a steam power plant.

- Commissioning of a steam power plant.

- Shut down of a steam power plant.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review