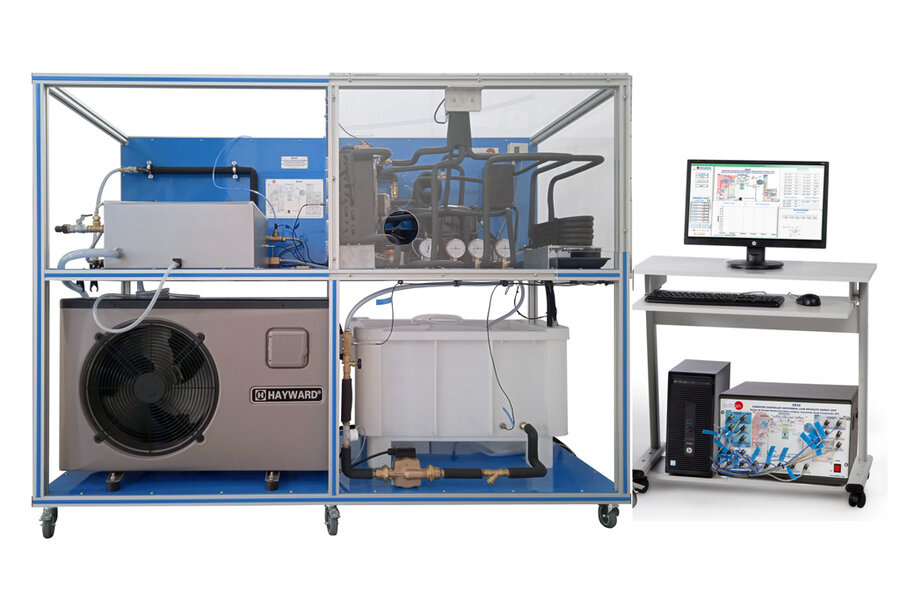

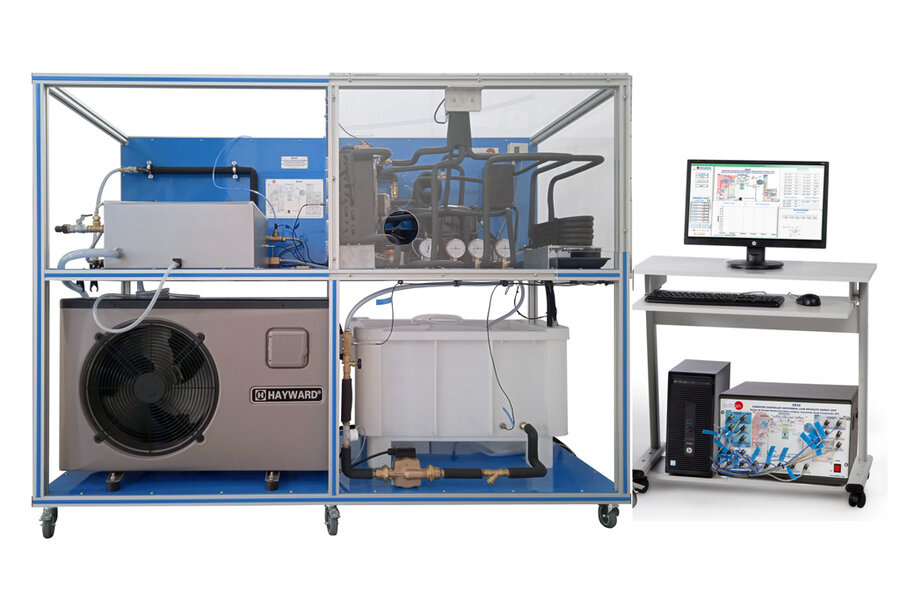

Computer Controlled Geothermal (low enthalpy) Energy Unit (EG5C)

PL-254273

The Computer Controlled Low Enthalpy Geothermal Energy Unit, “EG5C,” created by EDIBON, is designed to replicate the thermal properties of the earth using a cooling circuit, a water-filled tank with submerged pipes, and a heat pump. Additionally, a storage tank holds heated water to simulate domestic hot water.

The cooling circuit includes a compressor, an air condenser/evaporator, and two water condensers/evaporators. A four-way valve directs the refrigerant based on seasonal conditions, automatically selecting the correct exchanger to function as an evaporator or condenser as needed.

To simulate the consistent 15°C (59°F) ground temperature at a depth of 20 meters, a small water-filled tank and heat pump work to maintain this baseline. This temperature-controlled water then flows into a bath, where it heats or cools water circulating through the submerged pipes.

The unit’s cycle inversion valve enables switching between winter and summer modes. In winter, with ambient temperatures below 15°C, the ground’s warmth is harnessed for heating. In summer, when outdoor temperatures rise above 15°C, the ground water’s cooler temperature provides an effective source of cooling.

The unit is equipped with the EDIBON SCADA System, which includes the core unit, a Control Interface Box, a Data Acquisition Board, and software for computer control, data collection, and full management of process parameters.

- EG5C. Unit:

- Unit mounted in anodized aluminum frame and panels of painted steel.

- The unit includes wheels to facilitate its mobility.

- Main metallic elements made of stainless steel.

- Diagram in the front panel with distribution of the elements similar to the real one.

- Heat pump

- Sanitary water circuit

- Geothermal exchanger simulation

The complete unit includes as well:

- Advanced Real-Time SCADA.

- Open Control + Multicontrol + Real-Time Control.

- Specialized EDIBON Control Software based on LabVIEW.

- National Instruments Data Acquisition board.

- Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

- Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

- Capable of doing applied research, real industrial simulation, training courses, etc.

- Remote operation and control by the user and remote control for EDIBON technical support, are always included.

- Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic and Software).

- Designed and manufactured under several quality standards.

- Optional ICAI software to create, edit and carry out practical exercises, tests, exams, calculations, etc. Apart from monitoring user’s knowledge and progress reached.

- This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

- EG5C/CIB. Control Interface Box.

- EG5C/CCSOF. Computer Control + Data Acquisition + Data Management Software.

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with 8 manuals. Required services, Assembly and Installation, Interface and Control software, Starting-up, Safety, Maintenance, Calibration and Practices manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Study of geothermal energy using a geothermal heat pump system for heating and/or cooling.

- Study of the system with different ground temperatures.

- Determination of the inlet power, produced heat and coefficient of performance, working in heating mode. Water-water heat pump.

- Determination of the inlet power, produced heat and coefficient of performance, working in cooling mode. Water-water heat pump.

- Determination of the inlet power and valuation of the air temperatures, working in heating mode. Water-air heat pump.

- Determination of the inlet power and valuation of the air temperature, working in cooling mode. Water-air heat pump.

- Preparation of performance curves of the heat pump, working in heating mode, with different inlet and outlet temperatures. Waterwater heat pump.

- Preparation of performance curves of the heat pump, working in cooling mode, with different inlet and outlet temperatures. Waterwater heat pump.

- Lay out of the steam compression cycle in a P-H diagram and comparison with the ideal cycle. Water-water heat pump. Heating mode.

- Lay out of the steam compression cycle in a P-H diagram and comparison with the ideal cycle. Water-air heat pump. Heating mode.

- Preparation of the performance curves of the heat pump based on the properties of the refrigerant and at different condensation and evaporation temperatures. Water-water heat pump. Heating mode.

- Preparation of the performance curves of the heat pump based on the properties of the refrigerant and at different condensation and evaporation temperatures. Water-water heat pump. Cooling mode.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review