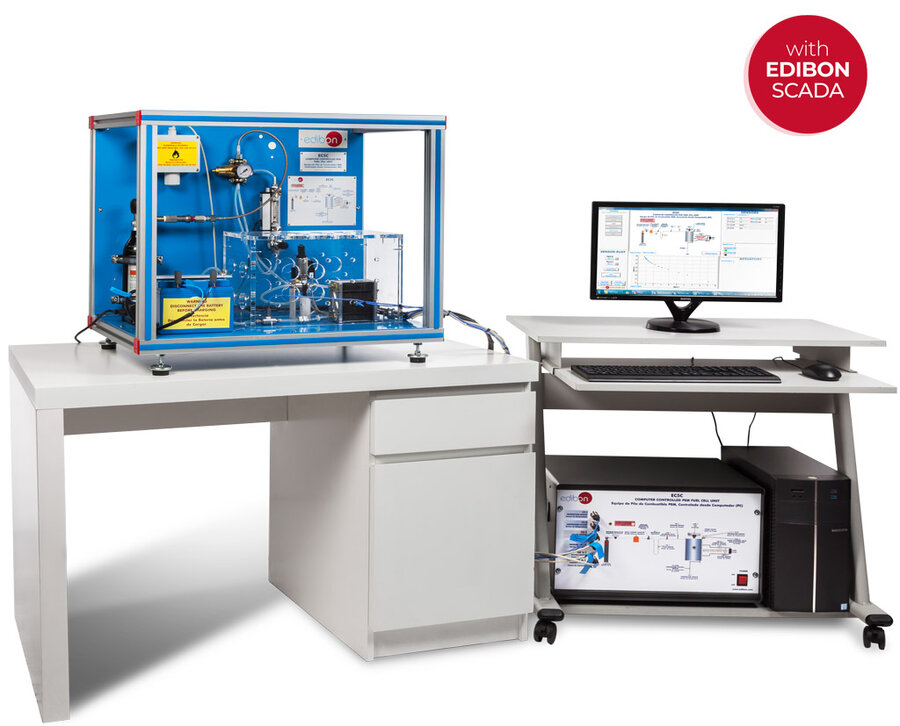

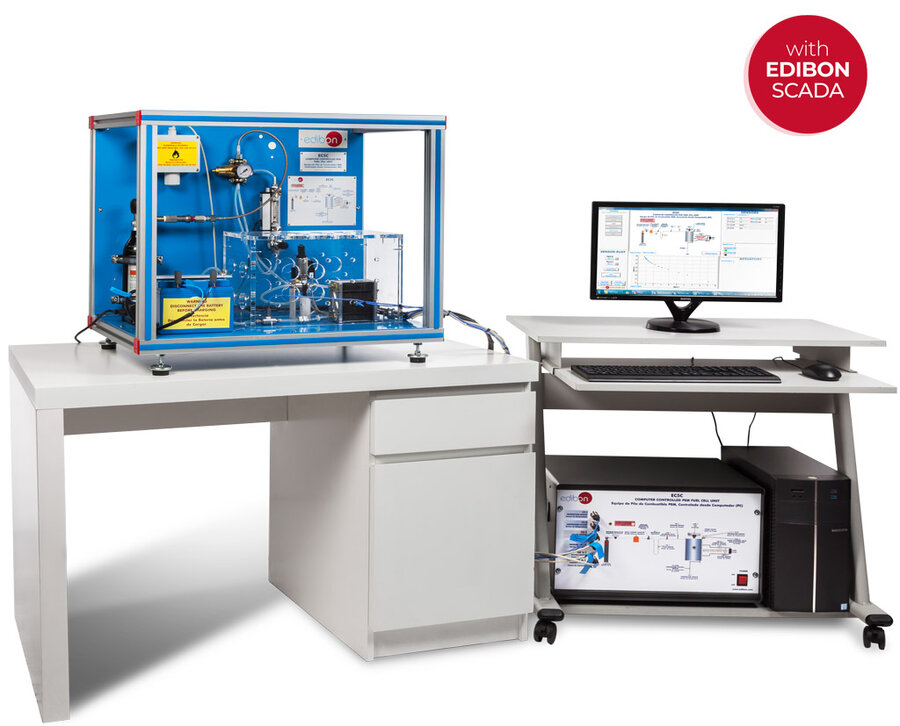

Computer Controlled PEM Fuel Cell Unit (EC5C)

PL-588545

The "EC5C" Computer Controlled PEM Fuel Cell Unit by EDIBON is designed to teach students the fundamentals of fuel cell technology, particularly focusing on proton exchange membrane (PEM) fuel cells. The unit allows for the calculation of essential parameters, such as power density, polarization curves, and efficiency, as well as how these values change based on reagent consumption and power output.

The EC5C comes with a 100 W PEM fuel cell stack, comprised of 24 channeled cells that facilitate airflow across the membrane, enabling hydrogen flow and the release of electrons. Each cell is separated by conductive plates, allowing for electron flow between cells. The system is self-humidifying, eliminating the need for external humidification, and includes a fan to provide adequate airflow and maintain operational temperature.

The unit addresses hydrogen storage needs with two pressure regulators: one for adjusting outlet pressure from an H₂ bottle (5-50 bar) and another for controlling inlet pressure to the stack (0-1 bar). For safety, two solenoid valves control the hydrogen flow—one valve shuts off the hydrogen supply when the unit is turned off to prevent leaks, while the other purges excess water and hydrogen to ensure proper functioning.

A load regulation system is included for studying the electrical output and creating operational curves for comparison with theoretical data. It features a variable power rheostat for adjusting generated power and includes a 12 V battery to power the unit's interface. Safety measures are integral, with short circuit protection for currents above 12 A and low-voltage shutoff at 12 V. Additionally, a hydrogen leak detector offers a detection range of 0-2% Vol and 0-100% L.E.L. (Lower Explosive Limit) for added security.

This unit is fully integrated with EDIBON's SCADA-based Computer Control System, which includes the unit itself, a Control Interface Box, a Data Acquisition Board, and software packages for process control, data collection, and comprehensive parameter management.

- EC5C. Unit:

- Bench-top unit.

- Anodized aluminum frame and panels made of painted steel.

- Main metallic elements made of stainless steel.

- Diagram in the front panel with distribution of the elements similar to the real one.

- Pressure regulator for the hydrogen inlet at the PEM fuel cell, range.

- Pressure regulator of the H2 bottle.

- Solenoid valve to supply H2

- Purge solenoid valve.

- Suitable tubes and hoses for their use with H2 with a high safety factor.

- Load module: Rheostat.

- Battery and charger.

- Fuel cell stack.

- Instrumentation.

- Safety measures and protections.

The complete unit includes as well:

- Advanced Real-Time SCADA.

- Open Control + Multicontrol + Real-Time Control.

- Specialized EDIBON Control Software based on LabVIEW.

- National Instruments Data Acquisition board.

- Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

- Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

- Capable of doing applied research, real industrial simulation, training courses, etc.

- Remote operation and control by the user and remote control for EDIBON technical support, are always included.

- Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic and Software).

- Designed and manufactured under several quality standards.

- Optional ICAI software to create, edit and carry out practical exercises, tests, exams, calculations, etc. Apart from monitoring user’s knowledge and progress reached.

- This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

- EC5C/CIB. Control Interface Box.

- EC5C/CCSOF. Computer Control + Data Acquisition + Data Management Software.

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with 8 manuals. Required services, Assembly and Installation, Interface and Control software, Starting-up, Safety, Maintenance, Calibration and Practices manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Study of the fundamental principles of operation of a proton exchange fuel cell (PEM).

- Study of the frame and main principles of a metal hydride bottle.

- Calculation of a fuel cell efficiency.

- Study of the influence of air consumption and hydrogen in the efficiency of a fuel cell.

- Study of the influence of generated power in the efficiency of a fuel cell.

- Determination of the current density - voltage characteristics of a fuel cell.

- Power density from a single cell and a stack of cells.

- Representation of the polarization curve of a fuel cell.

- Study of the influence of the reagents flows in the generation of electrical power.

- Study of the use of reagents and transport phenomena.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review