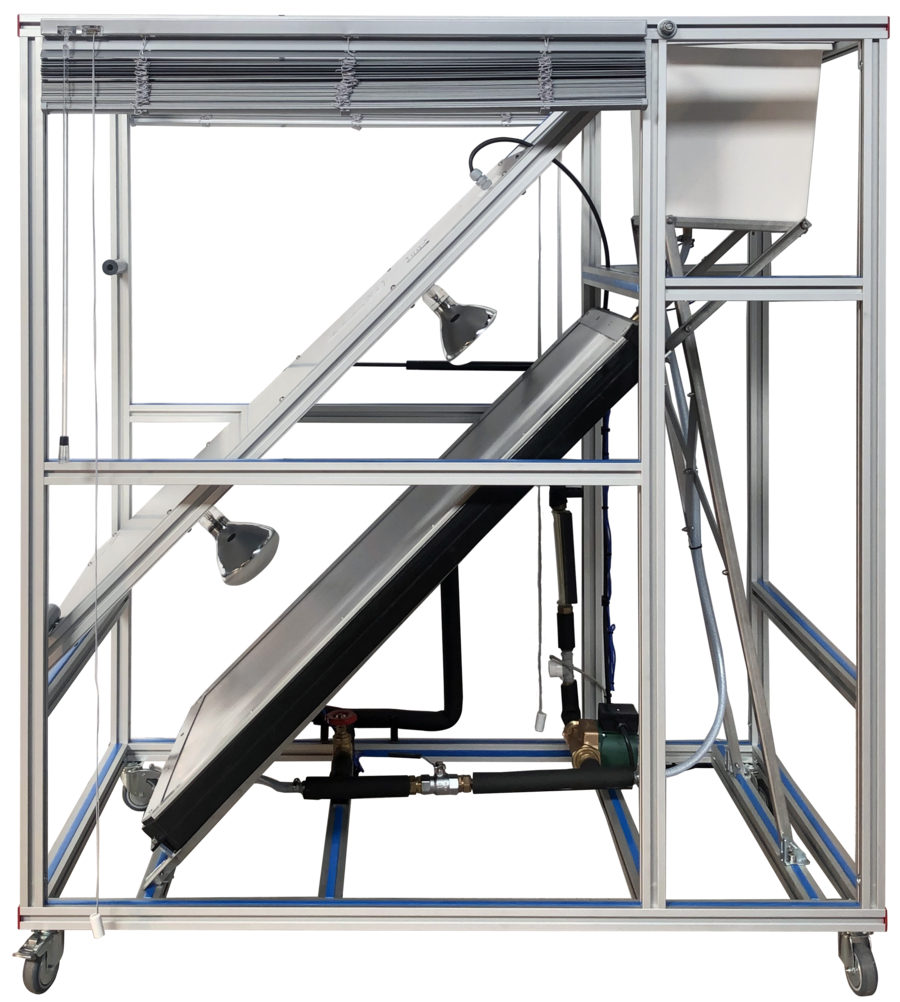

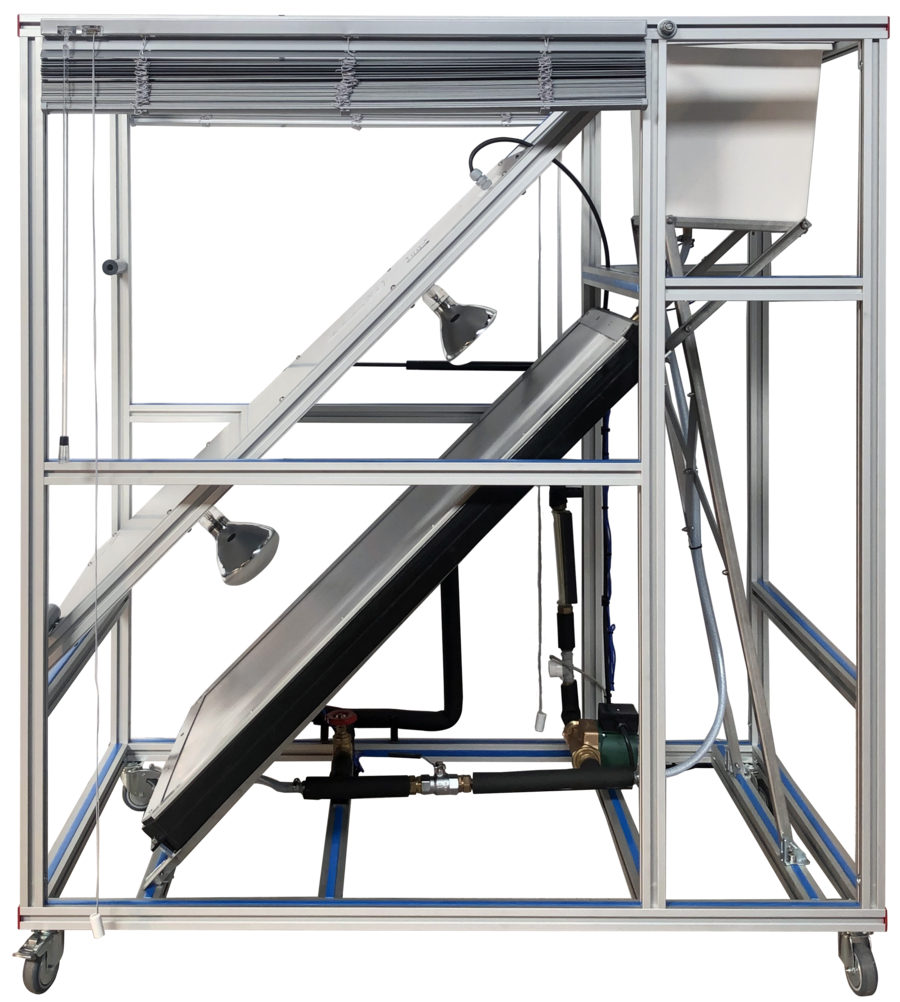

Computer Controlled Thermal Solar Energy Basic unit (MINI-EESTC)

PL-856084

The “MINI-EESTC” Computer Controlled Thermal Solar Energy Basic Unit is designed to effectively demonstrate the principles of solar thermal heating for domestic water. This compact unit utilizes a thermosiphon system and a traditional pumping system to convert solar energy into usable thermal energy. The simulated solar radiation is provided by powerful luminous sources.

The unit is comprised of the following key components:

- Thermal Solar Panel: Constructed from polycarbonate, this panel is mounted on a metal frame and features a conduit for the thermal fluid. Its design optimizes the geometrical shape of the absorbing surface to achieve maximum efficiency.

- Tank: The tank is built to meet established technical standards and is equipped for safe and effective operation. Hot water exits through an overflow positioned at the tank's top.

- Solar Simulator: The system includes lamps that emit radiation characteristics similar to sunlight, allowing for accurate simulation of solar heating conditions.

- Pumping System: This system supports both thermosiphon mode—where water circulates due to temperature differences without a pump—and pumping mode, where a pump actively moves the water.

- Sensors and Controls: The unit features five temperature sensors to monitor temperature at various points within the system. Additionally, a flowmeter and flow sensor measure the water flow through the pump and collector, ensuring effective operation.

- Valves: The unit is equipped with valves that facilitate operation in either thermosiphon or pumping mode, enhancing flexibility in demonstration.

Every necessary pipe and connection is included to ensure optimal performance of the unit.

This Computer Controlled Unit is integrated with the EDIBON Computer Control System (SCADA), which comprises the main unit, a Control Interface Box, a Data Acquisition Board, and software packages for computer control, data acquisition, and management of all process parameters.

- MINI-EESTC. Unit:

- Anodized aluminum frame and panels made of painted steel.

- The unit includes wheels to facilitate its mobility.

- Main metallic elements made of stainless steel.

- Diagram in the front panel with distribution of the elements similar to the real one.

- Solar panel (thermal solar collector).

- Tank of 30 l.

- Solar simulator.

- Pumping system.

- Five temperature sensors, type “J“, at different points of the unit.

- The unit includes two “Venetian” type blinds to reduce a direct visual contact with the lamps and to reduce the direct contact with the solar panel when the unit is working.

The complete unit includes as well:

- Advanced Real-Time SCADA.

- Open Control + Multicontrol + Real-Time Control.

- Specialized EDIBON Control Software based on LabVIEW.

- National Instruments Data Acquisition board (250 KS/s, kilo samples per second).

- Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

- Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

- Capable of doing applied research, real industrial simulation, training courses, etc.

- Remote operation and control by the user and remote control for EDIBON technical support, are always included.

- Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic and Software).

- Designed and manufactured under several quality standards.

- Optional ICAI software to create, edit and carry out practical exercises, tests, exams, calculations, etc. Apart from monitoring user’s knowledge and progress reached.

- This unit has been designed for future expansion and integration. A common expansion is the EDIBON Scada-Net (ESN) System which enables multiple students to simultaneously operate many units in a network.

- MINI-EESTC/CIB. Control Interface Box.

- MINI-EESTC/CCSOF. Computer Control + Data Acquisition + Data Management Software.

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with 8 manuals: Required services, Assembly and Installation, Interface and Control software, Starting-up, Safety, Maintenance, Calibration and Practices manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Study of the thermosiphon operation.

- Study of the luminosity profile of the lamps.

- Study of the efficiency of the solar panel.

- Study of the influence of the inclination angle of the lamp panel on the unit efficiency.

- Study of the relation between the flow and the temperature.

- Study of the energy balance of the solar collector.

- Experimental efficiency determination.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review