Computer Controlled and Touch Screen 1.5 kW Steam Power Plant (TPTV/1.5kW/CTS)

PL-981903

The Computer Controlled and Touch Screen 1.5 kW Steam Power Plant,"TPTV/1.5kW/CTS", allows the detailed study of the power generation cycle using steam as process fluid.

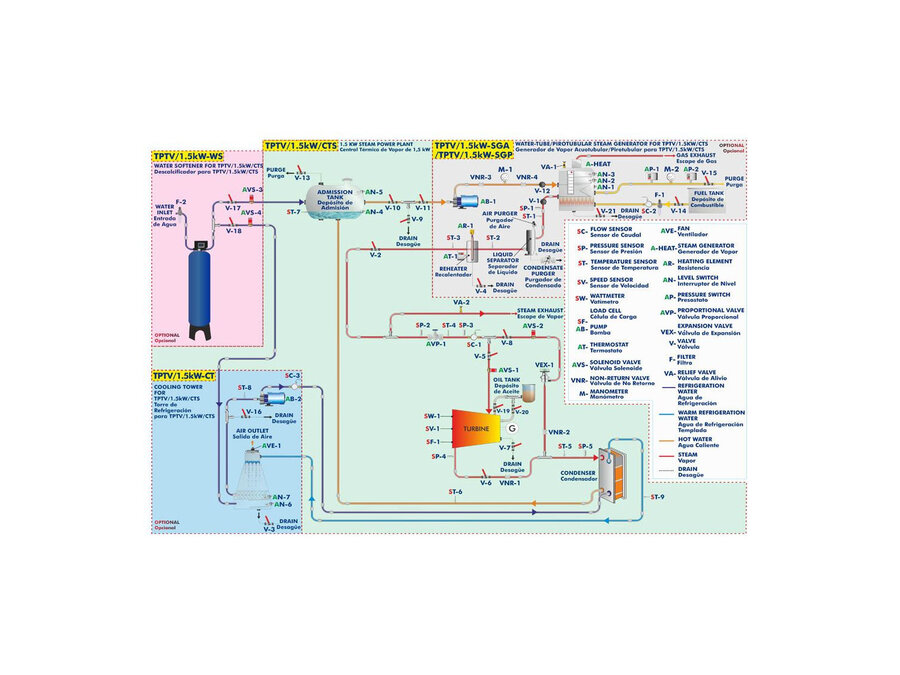

In addition to the main TPTV unit, the unit has three required units, Water Softener for TPTV/1.5kW/CTS, "TPTV/1.5kW-WS", Cooling Tower for TPTV/1.5kW/CTS, "TPTV/1.5kW-CT", and Water-tube Steam Generator for TPTV/1.5kW/CTS, "TPTV/1.5kW-SGA" or Water-tube Steam Generator for TPTV/1.5kW/CTS, "TPTV/1.5kW-SGP", which allow optimization of the unit and increase the degree of similarity of the 1.5 kW Steam Power Plant with a real steam power generation plant.

The incorporation of the Water Softener for TPTV/1.5kW/CTS, "TPTV/1.5kW-WS" makes it possible to eliminate the hardness of the mains water by incorporating a 40 l column of ion exchange resin, which retains the lime present in the water, exchanging the calcium cations for sodium cations. The decalcified water can flow into the Cooling Tower for TPTV/1.5kW/CTS, "TPTV/1.5kW-CT", or into the intake tank and, subsequently, into the Steam Generator of choice, ("TPTV/1.5kW-SGA" or "TPTV/1.5kW-SGP"), tank.

The decalcified water is stored in the Cooling Tower for TPTV/1.5kW/CTS, "TPTV/1.5kW-CT". If the water level is below the level switch AN-6, the unit will automatically fill the unit by opening the automatic valve AVS-4 until the level switch AN-7 is reached.

In case the water level is correct, the water is pumped to the condenser of the Steam Power Plant, "TPTV", to condense the expanded steam in the turbine, thus allowing the condensate to be returned to the intake tank. The refrigeration tower tank can be emptied manually by means of valves V-3 and V-16.

The inlet tank can therefore be filled directly with decalcified water at the start-up of the unit or it can be filled with the condensate return. In both cases, the purge valve V-13 must remain open to remove air from the tank and facilitate filling. If there is no water available, the AVS-3 valve will be opened, allowing the tank to be filled up to the level switch AN-5. The tank can be emptied manually by means of valves V-9 and V-10.

If the liquid level is sufficient, the water is pumped to the boiler. In the boiler, the water is progressively heated and pressurised by the diesel combustion process until the desired vapour conditions are obtained.

Once the process conditions are obtained, the steam passes through a liquid separator to remove any suspended droplets present in the steam generated in the Steam Generator of choice, ("TPTV/1.5kW-SGA" or "TPTV/1.5kW-SGP"). Once dry, the steam is reheated by passing through the installation’s resistance to obtain superheated steam.

To regulate the steam flow rate of the circuit, the installation has a proportional valve that throttles the flow rate of the installation, allowing it to operate in a wide range of steam flow rates. After passing through the proportional valve, the steam can take two different paths.

The first path allows the turbine to be bypassed by opening the AVS-2 valve, thus ensuring the integrity of the turbine until the desired process conditions are obtained. This bypass flows into the condenser where the steam is condensed, closing the cycle.

The second path allows the turbine to extract thermal energy from the steam, converting it into mechanical energy, which is converted into electrical energy by the generator. The rotational speed of the turbine, as well as the torque and the power generated are measured by different sensors in the turbine.

In order to optimize the rotation of the turbine, the turbine is equipped with a lubrication reservoir. In order to remove any condensation that may occur during the first moments of contact between the steam and the cold blades of the turbine, the turbine is equipped with a drain valve.

This computer controlled unit is supplied with the EDIBON Control System (SCADA), and includes: The unit itself + CTS + Control, Data Acquisition and Data Management Software Packages, for controlling the process and all parameters involved in the process.

GUIDED PRACTICAL EXERCISES INCLUDED IN THE MANUAL

- Study and analysis of the unit prior to its commissioning.

- Study, analysis and testing of the water softener.

- Study, analysis and testing of the boiler.

- Study, analysis of the Rankine cycle.

- Calibration of sensors.

MORE PRACTICAL EXERCISES TO BE DONE WITH THE UNIT

- Study, analysis and test of pressure in the circuit.

- Study of pressure and temperature control techniques in a steam thermal power plant.

- Study and analysis of the appropriate maintenance in a steam thermal power plant.

- Shutdown of a steam thermal power station.

- Determination of the water-steam ratio required by the plant.

- Study of the relationship between the powers delivered to the electricity grid and the steam flow rate.

- Study of the relationship between the powers delivered to the electrical grid and the steam pressure.

- Study of the ratio of the active power of the generator as a function of the steam flow rate in an isolated circuit (isolated mode).

- Study of the ratio of the active power of the generator as a function of the vapor pressure in an isolated circuit.

- Study of the relationship of the active power generation of the generator as a function of the vacuum pressure at the turbine outlet in an isolated circuit (isolated mode).

- Study of heat losses in pipes.

1 TPTV/1.5kW/CTS. Unit:

Anodized aluminum frame and panels made of painted steel.

The unit includes wheels to facilitate its mobility.

Main metallic elements made of stainless steel.

Diagram in the front panel with distribution of the elements similar to the real one.

Transparent panels to protect the unit that allows the user to observe the operation of the unit.

Transparent panels for the protection of the unit against steam leaks that allow the visualisation of the operation of the unit.

Local control of the plant by PLC-HMI system using a 10.1'' touch screen, allowing users to have an overview of the plant and operating conditions.

Thermally insulated units and piping with temperatures above 60 °C.

Intake tank in stainless steel or similar.

Turbine:

Power: 0.5 - 1.5 kWe.

Inlet conditions: superheated steam: 11 bar; temperature: 200 - 250 °C.

Outlet conditions: steam: 1 bar; temperature: 95 - 100 °C.

Condenser:

80 - 100 kW.

Refrigeration water: temperatura < 35 °C.

Work pressure: 1 bar.

Relief valve: 12 bar.

Proportional valve to control the working speed.

Solenoid valves to control the inlets and outlets of the unit.

Relief valve in the steam circuit.

Instrumentation:

Four pressure sensor, range 0 - 16 bar.

Seven “J” type temperature sensors, range: 0 - 500 °C.

Vortex type flow sensor for steam flow measurement, range: 0 - 200 kg/h.

Speed sensor.

Wattmeter.

The complete unit includes as well:

Advanced Real-Time SCADA.

Open Control + Multicontrol + Real-Time Control.

Specialized EDIBON Control Software.

Calibration exercises, which are included, teach the user how to calibrate a sensor and the importance of checking the accuracy of the sensors before taking measurements.

Projector and/or electronic whiteboard compatibility allows the unit to be explained and demonstrated to an entire class at one time.

Capable of doing applied research, real industrial simulation, training courses, etc.

Remote operation and control by the user and remote control for EDIBON technical support, are always included.

Totally safe, utilizing 4 safety systems (Mechanical, Electrical, Electronic & Software).

Designed and manufactured under several quality standards.

Required elements (Not included):

Required: “TPTV/1.5kW-WS” and “TPTV/1.5kW-CT”. Of the rest of the elements, additionally, only one is required:

- TPTV/1.5kW-WS. Water Softener for TPTV/1.5kW/CTS.

Unit for treating hardness in water.

Ion exchange resin.

Salt tank for the regeneration of the ion exchange resin.

Working pressure from 2 - 8 bar.

Working temperature of 10 - 40 °C.

Valve system that allows modulating the hardness of the output water.

Water hardness kit included.

Solenoid valves to control the inlet and outlet of the unit.

Drain valves.

Dimensions: 1000 x 1000 x 1000 mm approx. (39.37 x 39.37 x 39.37 inches approx.)

Weight: 50 kg approx. (110 pounds approx.)

- TPTV/1.5kW-CT. Cooling Tower for TPTV/1.5kW/CTS.

Refrigeration unit made of fiberglass or similar.

Water tank included.

Cooling capacity 80 - 100 kW.

Fan to force air into the cooling tower.

Antibacterial filling material.

Water pumping system.

Solenoid valves to control the inlet and outlet of the unit.

Drain valves.

Instrumentation:

Cooling water flow sensor, range 0 - 1000 l/min.

Temperature sensor type “J”, measuring range up to 500 °C.

Flow sensors.

Dimensions: 1600 x 1000 x 3000 mm approx. (62.99 x 39.37 x 118.11 inches approx.)

Weight: 200 kg approx. (440 pounds approx.)

- TPTV/1.5kW-SGA. Water-tube Steam Generator for TPTV/1.5kW/CTS.

Water-tube high energy efficiency and easy maintenance steam generator.

Instantaneous steam generation.

Transparent panels to protect the unit against steam leaks, allowing the operation of the unit to be visualised.

Thermally insulated unit and piping with temperatures above 60 °C.

Drainage at the bottom to allow the tank to be completely emptied.

External insulation.

Design pressure: 12 bar.

Design temperature: 180 - 210 ºC.

Power: 120 - 180 kW approx.

Includes pumping system for water transfer.

Liquid separator.

Reheater: 10 kW.

Includes liquid and/or gaseous fuel burner.

Operating and safety pressure switch.

Control, programming and monitoring of operating variables.

Pressure safety valve.

Solenoid valves to control the inputs and outputs of the unit.

Instrumentation:

Pressure sensor, range: 0 - 16 bar.

“J” type temperature sensors, range: 0 - 500 °C.

Fuel flow sensor, range 40 - 500 ml/min.

Dimensions: 1200 x 1200 x 1800 mm approx. (47.24 x 47.24 x 70.86 inches approx.)

Weight: 500 kg approx. (1102 pounds approx.)

- TPTV/1.5kW-SGP. Water-tube Steam Generator for TPTV/1.5kW/CTS.

Pirotubular high energy efficiency and easy maintenance steam generator.

300 l aprox tank for steam storage.

Transparent panels to protect the unit against steam leaks, allowing the operation of the unit to be visualised.

Thermally insulated unit and piping with temperatures above 60 °C.

Drainage at the bottom to allow the tank to be completely emptied.

External insulation.

Design pressure: 12 bar.

Design temperature: 180 - 210 °C.

Power: 120 - 180 kW approx.

Includes pumping system for water transfer.

Liquid separator.

Reheater: 10 kW.

Includes liquid and/or gaseous fuel burner.

Operating and safety pressure switch.

Control, programming and monitoring of operating variables.

Pressure safety valve.

Solenoid valves to control the inputs and outputs of the unit.

Instrumentation:

Pressure sensor, range: 0 - 16 bar.

“J” type temperature sensors, range: 0 - 500 °C.

Fuel flow sensor, range 40 - 360 ml/min.

Dimensions: 2500 x 1250 x 4250 mm approx. (98.42 x 49.21 x 167.32 inches approx.)

Weight: 1200 kg approx. (2645 pounds approx.)

2 TPTV/1.5kW/CTS/PLC. Control and Monitoring:

It is a system composed of an interface that includes PLC modules such as CPU, digital I/O module, analog I/O module, communications module, etc. and a control box with HMI display.

PLC interface:

PLC controller.

Digital I/O modules:

Digital inputs; input range 0 V to 24 V.

Digital outputs; relay output.

Analogue I/O modules:

Analog inputs; 16-bit resolution. Input range -10 V to +10 V.

Analog outputs; 16-bit resolution. Output range -10 V to +10 V.

Connectors and Communication Ports:

Ethernet connector.

USB connector.

The PLC interface may change at any moment, providing the same or better features than those required for the unit.

HMI control box and display:

HMI display:

Touch Screen: Analog Resistive.

Size: 10” 16:9 TFT.

Resolution: 1024 x 600, WVGA.

Colors: 64 K.

Ethernet port.

3 TPTV/1.5kW/CTS/CCSOF. Supervision Software + Control Software + Data Acquisition Software + Data Management Software:

SCADA System is composed of four software package with the following features:

The Supervision Software is in charge of monitoring in real time start and stop elements, unexpected conditions and process evolution. In case of being necessary, it actuates on the system and notifies the user the incorrect operations.

The Control Software allows to manage multiple process and variables in real time either a manual way or automatic way. Several type of algorithms of control such PID CONTROL are implemented depending on the field of study.

The Data Acquisition Software focus on measuring and processing signals from the process with very high accuracy getting a synchronized and fast response of the system. A calibration system is part of this software to adjust the sensor measurements.

The Data Management Software stores and represents, alarms, variables and process evolution in real time both in a graphic format and in a numeric format such time charts or process diagram. Printable reports can be generated or historian data can be loaded to study the experiments in detail.

The Software is open and flexible architecture that facilities to access different work levels both instructors and students. It is supported by current Windows operating system and industrial standards. The graphical user interface is intuitive and user- friendly.

4 Cables and Accessories, for normal operation.

5 Manuals:

This unit is supplied with 8 manuals: Required services, Assembly and Installation, Control software, Starting-up, Safety, Maintenance, Calibration & Practices manuals.

* References 1 to 5 are the main items: TPTV/1.5kW/CTS + TPTV/1.5kW/CTS/PLC + TPTV/1.5kW/CTS/CCSOF + Cables and Accessories + Manuals are included in the minimum supply for enabling normal and full operation.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review