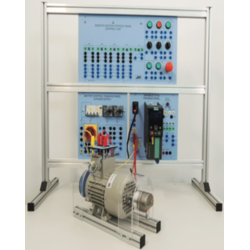

Hydraulic and Electro-Hydraulic Application (AE-HD)

PL-450313

The Pneumatic and Electro-Pneumatic Application, "AE-NS", by EDIBON is a modular system equipped with a variety of optional kits and components, allowing users to configure pneumatic and electro-pneumatic circuits based on their specific learning or training needs.

The application offers several optional pneumatic kits designed for comprehensive studies on industrial pneumatic circuit management and operation. These kits include:

- PK-K0 – Fundamentals Kit: Contains components for basic pneumatic circuit concepts.

- PK-K1 – Advanced Pneumatics Kit: Covers both fundamental and advanced pneumatic concepts.

- PK-K1UP – Electro-Pneumatics Upgrade Kit: Adds modules to the PK-K1, enabling users to study fundamental electro-pneumatic circuit concepts.

- PK-K2 – Electro-Pneumatics Kit: Provides components for both basic and advanced electro-pneumatic concepts.

- PK-K3 – Pneumatic Actuators Kit: Focuses on common pneumatic actuators, including rotary motors.

- PK-K4 – Measurement and Proportional Control Kit: A computer-controlled kit that enables proportional control and analog signal use with pneumatic actuators, facilitating PID control via computer.

- PK-K5 – Vacuum Technology Kit: Introduces the essential components of vacuum circuits and includes various cup types for comparative study.

- PK-K6 – Troubleshooting Kit: Contains defective components to teach students to identify and troubleshoot common pneumatic issues.

For added functionality, the EDIBON PLC unit is compatible with the PK-K2 kits, enabling PLC control of pneumatic and electro-pneumatic components for advanced, hands-on experience.

Additional units are available for airflow and pressure supply, as well as customizable workbenches that accommodate one or two work areas.

- AE-HD APPLICATION:

- Work with a working hydraulic pressure of 50 bar.

- The components include quick and self-sealing connectors with built-in Stop Mechanism.

- Are attached to a screen printed metallic plate with the name and the standard symbol of the component. These metallic plates are designed to be placed on the EDIBON workbenches

Optional kits of Pneumatic components:

- HK-K0. Kit to Study the Hydraulics Fundamentals.

- HK-K1. Hydraulic Components Kit.

- HK-K1UP. Upgrade Kit for the HK-K1 to Understand the Principles of ElectroHydraulic.

- HK-K2. Electro-Hydraulics Components Kit.

- HK-K3. Hydraulic Actuators Kit.

- HK-K4. Measurement and Proportional Control in Hydraulics Kit.

- HK-K5. Hydrostatic Steering System Kit:.

- HK-K6. Hydraulic and Electro-Hydraulic Troubleshooting Kit.

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with 8 manuals. Required services, Assembly and Installation, Interface and Control software, Starting-up, Safety, Maintenance, Calibration and Practices manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

HK-K0, Kit to study the hydraulics fundamentals:

- Identification of components.

- Hydraulic group.

- Direct discharge from the pump to the tank.

- Hydraulic cylinder activation by a 4/3 directional valve.

- Speed control of the double effect hydraulic cylinder.

- Flow control with tank bypass.

HK-K1, Hydraulics kit:

- Identification of elements.

- Hydraulic power unit.

- Direct discharge of the pump to the tank.

- Discharge of the pump through of a vacuum discharge valve.

- Operation of valves with manual activation.

- Manual activation of a double effect cylinder.

- Speed adjustment of a double effect cylinder.

- Activation of a double effect cylinder with different loads.

- Activation of a hydraulic motor.

- Flow calculation of hydraulic fluid.

- Study of load losses with different size pipes.

- Study of load losses with different length pipes.

HK-K1UP, Upgrade kit for the HK-K1 to understand the principles of Electro-Hydraulic:

- Identification of elements.

- Hydraulic power unit.

- Direct discharge of the pump to the tank.

- Operation of valves with electric activation.

- Activation of a double effect cylinder with a solenoid valve.

- Activation of a double effect cylinder with different loads.

- Speed adjustment of a double effect cylinder.

- Activation of a hydraulic motor.

- Electro-hydraulic control with solenoid valves.

- Pressure control through a pressure switch with electric contact.

HK-K2, Electro-Hydraulics kit:

- Identification of elements.

- Hydraulic power unit.

- Direct discharge of the pump to the tank.

- Operation of valves with electric activation.

- Activation of a double effect cylinder with a solenoid valve.

- Activation of a double effect cylinder with different loads.

- Speed adjustment of a double effect cylinder.

- Activation of a hydraulic motor.

- Flow calculation of hydraulic fluid.

- Study of load losses with different size pipes.

- Study of load losses with different length pipes.

- Electro-hydraulic control with solenoid valves.

- Pressure control through a pressure switch with electric contact.

HK-K3, Hydraulic Actuators kit:

- Identification of elements.

- Activation of a double effect cylinder.

- Activation of a hydraulic motor.

- Activation of a double-rod cylinder.

- Activation of a double effect linear actuator.

- Study of the characteristics and operation of a 6/3 manual operated directional valve.

- Hydraulic "OR" valve operation.

- Study of the characteristics and operation of a directional valve activated by joystick.

- Study of hydraulic actuators with locking in middle positions.

HK-K4, Measurement and Proportional Control in Hydraulics kit:

- Identification of elements.

- Familiarization with data acquisition and processing of system signals from PC.

- Operation of the Digital Flow Sensor.

- Operation of the Capacitive proximity sensor from PC.

- Operation of the Inductive proximity sensor from PC.

- Operation of the Optical proximity sensor form PC.

- Operation of the Fiber optic photoelectric sensor from PC.

- Operation of the Diffuse-reflective photoelectric sensor from PC.

- Operation of the Polarized retroreflective photoelectric sensor from PC.

- Operation of the Background suppression photoelectric sensor from PC.

- Proportional control of a proportional valve from PC.

- Analog measurement of pressure level from PC.

- Analog measurement of flow level from PC.

- PID control loop of the flow level from PC.

- Analog position sensor of the pneumatic linear actuator from PC.

- PID control loop of the position of a pneumatic linear actuator from PC.

HK-K5, Hydraulic Steering System kit:

- Identification of elements.

- Study of a Steering hydrostatic system.

- Determination of parameters of a steering system.

- Study of the orbitol operation.

- Configuration of a steering systems.

- Study of a pressure spike suppression system.

- Pressure spike suppression valve.

HK-K6, Hydraulics and Electro-Hydraulics Troubleshooting kit:

- Familiarization with most common failures of hydraulic components.

- Study a faulty pressure limiting valve.

- Study a faulty pilot operated pressure limiting valve.

- Study a faulty adjustable flow control valve.

- Study a faulty check valve.

- Study a faulty shut-off valve.

- Study a faulty 4/3 manual operated directional valve with H-center.

- Study a faulty 4/3 solenoid valve.

- Study a clogged pipe.

- Study a faulty double effect cylinder.

AE-PLC-PAN (also available with others PLC manufacturers): The practices available with the HK-K2 are:

- Activation of a double effect cylinder with PLC.

- Activation of a hydraulic motor with PLC.

- Electro-hydraulic control by a 4/2 solenoid valve activated from PLC.

- Electro- hydraulic control by 4/3 solenoid valve activated from PLC.

- Pressure control with PLC.

- Creation a hydraulic sequence with the PLC.

- Using variables.

- Using digital inputs I.

- Using digital inputs II.

- Testing digital inputs (PLC-PAN-K1).

- Using digital outputs.

- Testing digital outputs.

- Using analog signals I (PLC-PAN-K1 and PLC-PAN-K2).

- Using analog signals II (PLC-PAN-K1 and PLC-PAN-K2).

- Square wave generator.

- HMI simple program (PLC-PAN-K3 or PLC-PAN-K4).

- Using digital outputs with HMI device I (PLC-PAN-K3 or PLCPAN-K4).

- Using digital outputs with HMI device II (PLC-PAN-K3 or PLCPAN-K4).

- Reading data from a register with the HMI device (PLC- PAN-K3 or PLC-PAN-K4).

- Writing data to a register with the HMI device (PLC-PAN-K3 or PLC-PAN-K4).

- Switching screens of the HMI device (PLC-PAN-K3 or PLC- PAN-K4).

- Internet connection of the PLC unit (PLC-PAN-K5).

- Control digital inputs with a web server application (PLC- PAN-K5).

- Control digital outputs with a web server application (PLC- PAN-K5).

- Control analog inputs with a web server application (PLC- PAN-K5).

- Control analog outputs with a web server application (PLC- PAN-K5).

AE-PLC-SIE-UB (also available with others PLC manufacturers):

- Activation of a double effect cylinder with PLC.

- Activation of a hydraulic motor with PLC.

- Electro-hydraulic control by a 4/2 solenoid valve activated from PLC.

- Electro- hydraulic control by 4/3 solenoid valve activated from PLC.

- Pressure control with PLC.

- Creation a hydraulic sequence with the PLC.

- Using variables.

- Using digital inputs I.

- Using digital inputs II.

- Testing digital inputs (SIE-PLC-K1).

- Using digital outputs.

- Testing digital outputs.

- Using analog signals I (SIE-PLC-K1 and SIE-PLC-K2).

- Using analog signals II (SIE-PLC-K1 and SIE-PLC-K2).

- Square wave generator.

- HMI simple program (SIE-PLC-K3 or SIE-PLC-K4).

- Using digital outputs with HMI device I (SIE-PLC-K3 or SIE-PLC-K4).

- Using digital outputs with HMI device II (SIE-PLC-K3 or SIE-PLC-K4).

- Reading data from a register with the HMI device (SIE-PLC-K3 or SIE-PLC-K4).

- Writing data to a register with the HMI device (SIE-PLC-K3 or SIE-PLC-K4).

- Switching screens of the HMI device (SIE-PLC-K3 or SIE-PLC-K4).

- Internet connection of the PLC unit (SIE-PLC-K5).

- Control digital inputs with a web server application (SIE-PLC-K5).

- Control digital outputs with a web server application (SIE-PLC-K5).

- Control analog inputs with a web server application (SIE-PLC-K5).

- Control analog outputs with a web server application (SIE-PLC-K5).

AE-PLC-AB-UB (also available with others PLC manufacturers):

- Activation of a double effect cylinder with PLC.

- Activation of a hydraulic motor with PLC.

- Electro-hydraulic control by a 4/2 solenoid valve activated from PLC.

- Electro- hydraulic control by 4/3 solenoid valve activated from PLC.

- Pressure control with PLC.

- Creation a hydraulic sequence with the PLC.

- Using variables.

- Using digital inputs I.

- Using digital inputs II.

- Testing digital inputs (AB-PLC-K1).

- Using digital outputs.

- Testing digital outputs.

- Using analog signals I (AB-PLC-K1 and AB-PLC-K2).

- Using analog signals II (AB-PLC-K1 and AB-PLC-K2).

- Square wave generator.

- HMI simple program (AB-PLC-K3 or AB-PLC-K4).

- Using digital outputs with HMI device I (AB-PLC-K3 or AB-PLC-K4).

- Using digital outputs with HMI device II (AB-PLC-K3 or AB-PLC-K4).

- Reading data from a register with the HMI device (AB-PLC-K3 or AB-PLC-K4).

- Writing data to a register with the HMI device (AB-PLC-K3 or AB-PLC-K4).

- Switching screens of the HMI device (AB-PLC-K3 or AB-PLC-K4).

- Internet connection of the PLC unit (AB-PLC-K5).

- Control digital inputs with a web server application (AB-PLC-K5).

- Control digital outputs with a web server application (AB-PLC-K5).

- Control analog inputs with a web server application (AB-PLC-K5).

- Control analog outputs with a web server application (AB-PLC-K5).

AE-PLC-OMR (also available with others PLC manufacturers):

- Activation of a double effect cylinder with PLC.

- Activation of a hydraulic motor with PLC.

- Electro-hydraulic control by a 4/2 solenoid valve activated from PLC.

- Electro- hydraulic control by 4/3 solenoid valve activated from PLC.

- Pressure control with PLC.

- Creation a hydraulic sequence with the PLC.

- Using variables.

- Using digital inputs I.

- Using digital inputs II.

- Testing digital inputs (OMR-PLC-K1).

- Using digital outputs.

- Testing digital outputs.

- Using analog signals I (OMR-PLC-K1 and OMR-PLC-K2).

- Using analog signals II (OMR-PLC-K1 and OMR-PLC-K2).

- Square wave generator.

- HMI simple program (OMR-PLC-K3 or OMR-PLC-K4).

- Using digital outputs with HMI device I (OMR-PLC-K3 or PLCOMR-K4).

- Using digital outputs with HMI device II (OMR-PLC-K3 or PLCOMR-K4).

- Reading data from a register with the HMI device (OMR-PLC-K3 or OMR-PLC-K4).

- Writing data to a register with the HMI device (OMR-PLC-K3 or OMR-PLC-K4).

- Switching screens of the HMI device (OMR-PLC-K3 or OMR-PLC-K4).

- Internet connection of the PLC unit (OMR-PLC-K5).

- Control digital inputs with a web server application (OMR-PLC-K5).

- Control digital outputs with a web server application (OMR-PLC-K5).

- Control analog inputs with a web server application (OMR-PLC-K5).

- Control analog outputs with a web server application (OMR-PLC-K5).

AE-PLC-MIT-UB (also available with others PLC manufacturers):

- Activation of a double effect cylinder with PLC.

- Activation of a hydraulic motor with PLC.

- Electro-hydraulic control by a 4/2 solenoid valve activated from PLC.

- Electro- hydraulic control by 4/3 solenoid valve activated from PLC.

- Pressure control with PLC.

- Creation a hydraulic sequence with the PLC.

- Using variables.

- Using digital inputs I.

- Using digital inputs II.

- Testing digital inputs (MIT-PLC-K1).

- Using digital outputs.

- Testing digital outputs.

- Using analog signals I (MIT-PLC-K1 and MIT-PLC-K2).

- Using analog signals II (MIT-PLC-K1 and MIT-PLC-K2).

- Square wave generator.

- HMI simple program (MIT-PLC-K3 or MIT-PLC-K4).

- Using digital outputs with HMI device I (MIT-PLC-K3 or MIT-PLC-K4).

- Using digital outputs with HMI device II (MIT-PLC-K3 or MIT-PLC-K4).

- Reading data from a register with the HMI device (MIT-PLC-K3 or MIT-PLC-K4).

- Writing data to a register with the HMI device (MIT-PLC-K3 or MIT-PLC-K4).

- Switching screens of the HMI device (MIT-PLC-K3 or PLC-PAN-K4).

- Several other exercises can be done and designed by the user.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review