Rotary Table Workstation: Feeding, Quality Control and Assembly (dimensional study) (AE-PLC-MR1)

PL-800181

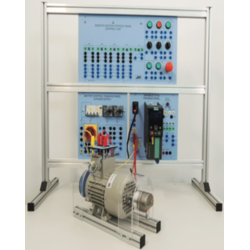

The “AE-PLC-MR1” is an automatic rotary table equipped with an integrated parts feeder, quality control, and assembly system. The system includes vertical storage that supplies parts one by one to the rotary table. Once a part is placed on the table, a quality control system verifies its dimensions and material. If the part meets the requirements, it is assembled with a lid; otherwise, it is automatically discarded by the rotary table. The workstation is designed as a modular system to facilitate understanding and training.

The main components of the unit include: the PLC, composed of a CPU and all necessary expansion modules to ensure proper operation; the Control Panel, with start/stop, emergency, and reset buttons, as well as status indicators; the Pneumatic Circuit, which features solenoid valves, filters, regulators, and all required components to guarantee proper functioning; and the Workstation, built with real industrial components such as reed sensors, presence sensors, a DC motor, inductive sensors, and an 8-position rotary table.

This unit is designed to operate as a standalone workstation or as part of a Flexible Manufacturing System (FMS) when integrated with other EDIBON stations. (See section “6.-MECHATRONICS, AUTOMATION AND COMPUMECHATRONICS” for the complete FMS product list.)

The system is divided into several functional sections. The Air Treatment System includes a filter-regulator block with water trap, shut-off valve, and a dual-scale manometer to visualize supply pressure. The Parts Feeding Section uses a double-acting cylinder with adjustable airflow valves to supply parts from vertical storage one at a time. The Parts Displacement Section features the rotary table driven by a DC motor with encoder and brake, transporting parts through the verification and classification areas.

The Parts Verification Section uses height sensors and inductive sensors to determine whether parts have a central hole and whether they are made of metal or PVC. Based on this analysis, the Parts Sorting Section uses telescopic suction cups to discard non-compliant parts or activates a rotary actuator/gripper to store acceptable parts in the designated area. The system also includes a Signaling Tower (green, yellow, red LEDs) to indicate operational status.

Finally, the Solenoid Valve Block includes twelve valves: two 3/2 monostable, six 5/2 monostable, and four 5/2 bistable valves. The Electrical Terminal Block provides access to all unit signals for manual testing, with color-coded terminals (yellow for inputs, blue for outputs, grey for power and PE) and clear labeling for ease of identification.

- AE-PLC-MR1. Unit:

- Table with four wheels with brakes mounted with aluminum profiles.

- Programming software PLC:

- Programming software PLC:

- Programming software developed according to the norm IEC 61131-3.

- Compatible with Windows operating systems.

- 5 programming languages:

- Ladder diagram (LD).

- Structured text (ST).

- Instructions list (IL).

- Sequential function chart (SFC).

- Function block diagram (FBD).

- Programming, service and remote diagnostics.

- Minimun program size.

- Powerful debugging and monitoring tools.

- Support for user-created functions and function blocks.

- Save project files in plc.

- Quick start tutorial example included.

- Electrical Panel:

- Differential magneto-thermal switch.

- Power supply of 24 VDC.

- Control Panel:

- Mushroom head emergency stop push button switch.

- Start and stop pushbuttons.

- Switch for manual or automatic operation.

- Light indicator.

- Led stack light.

- Fault Injection Key Box Module:

- Red key box module with switches inside.

- DB37 connectors.

- Each fault is generated via toggle switches.

- Electrical Components:

- Round table with 8 positions.

- DC motor.

- 1 dryve D8, step/direction stepper motor control system.

- Pneumatic Circuit:

- Air treatment unit:

- Filter-regulator with water trap.

- Manometer with double scale indicator.

- Shut-off valve.

- 24 flow control valves.

- 8 single acting pneumatic actuators.

- 2 pneumatic solenoid valves 3/2 monostable.

- 6 pneumatic solenoid valves 5/2 monostable.

- 4 double acting pneumatic actuator.

- 4 pneumatic solenoid valves 5/2 bistable.

- Individually identified tubes and push in fittings.

- Vacuum Circuit:

- 2 Telescopic suction cup.

- 2 Venturi effect vacuum ejector.

- 2 pneumatic solenoid valves 3/2 monostable.

- 2 pressure relief valve.

- Sensors:

- 16 reed effect limit switches.

- 2 capacitive sensors.

- Inductive sensor.

- Height sensor.

- Encoder of the rotating table

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with manuals: Required services, Assembly and Installation, Control software, Starting-up, Safety, Maintenance and Practices manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Introduction to the flexible manufacturing system: Identification of unit components.

- Introduction to pneumatics and electro-pneumatics: Identification of components.

- Configuration of a pneumatic application.

- Operation of pneumatic system: Introduction to vacuum technology and pneumatic actuators.

- Study of sensor detection.

- Manual control of a rotary table.

- Automatic control of a rotary table.

- Industrial application example.

- Industrial application tuning.

- Fault inserted analysis and diagnosis.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review