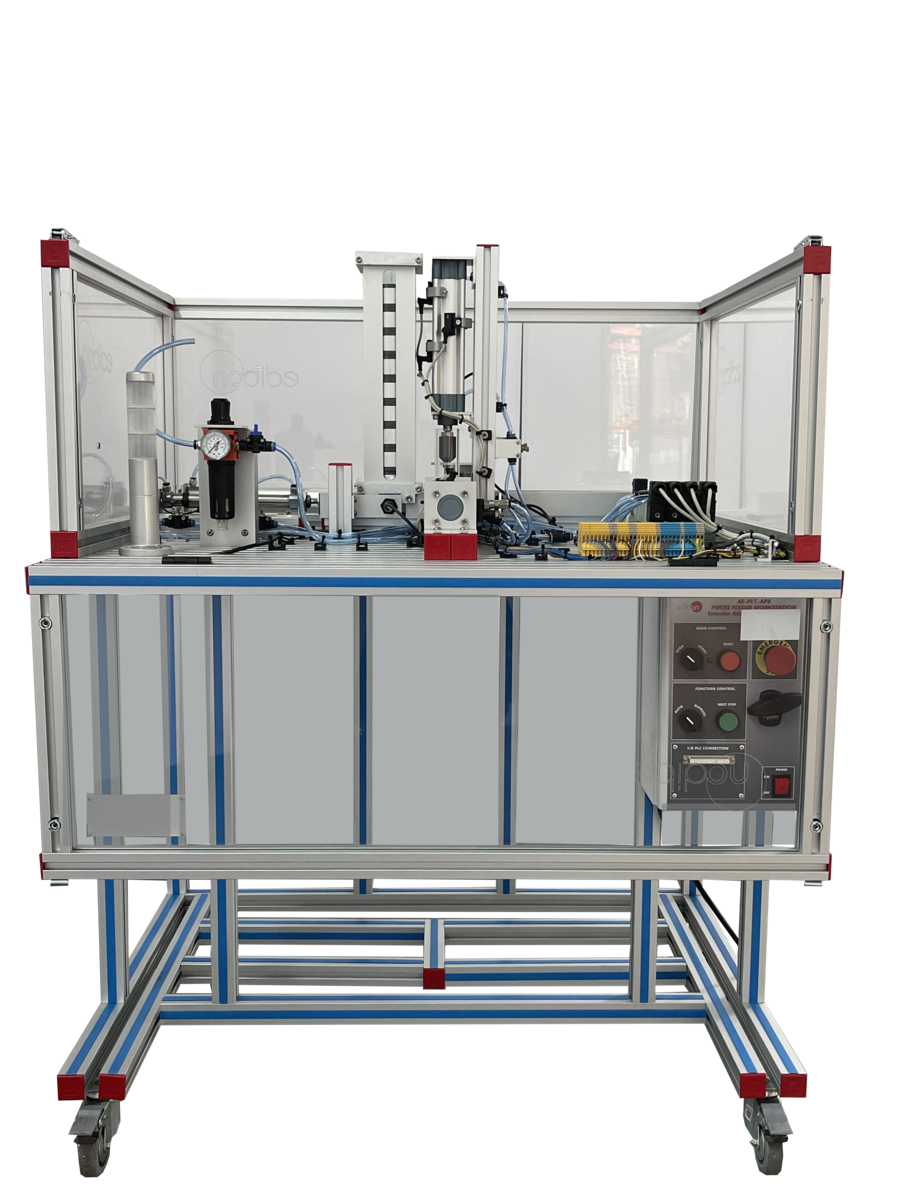

Part Feeder Workstation (AE-PLC-APS)

PL-654339

The Pieces Feeder Workstation, “AE-PLC-APS”, is a training unit that operates using pneumatic and electropneumatic technologies. Its main function is to supply and verify parts one by one. A pneumatic cylinder feeds each part individually, which is then verified to determine if it meets the required characteristics. Depending on the verification result, the part is either sent to the outlet zone or discarded. This workstation allows users to learn the fundamentals of pneumatics and electropneumatics without requiring prior experience.

The system is composed of two main sections: the control panel and the sensor/actuator section. The control panel includes all push-buttons and switches required for operation, as well as internal differential magnetothermal protection to ensure user safety. The sensor and electropneumatic actuator section includes reed and capacitive sensors, single and double-acting cylinders, solenoid valves (3/2 and 5/2), and an Ethernet/IP remote I/O module for automatic control of the entire process.

The system is organized into several modules. The air treatment unit features a filter-regulator block with a water trap, shut-off valve, and a dual-scale manometer. The piece feeder module stores the parts vertically and supplies them using a double-acting cylinder with speed-regulated airflow valves. The piece verifier module checks whether the parts have a central hole, using a double-acting cylinder with three sensors. Verified parts are then processed by the piece displacer module, which moves them to the classification area using another double-acting cylinder, equipped with adjustable airflow valves and piloted check valves for speed and position control.

The piece classification module sorts the parts: good parts are directed to the correct area by a single-acting classification cylinder, while defective ones are automatically discarded. The unit also includes a stack light (green, yellow, and red LEDs) to indicate system status, a solenoid valve block with five valves (three 3/2 and two 5/2), and an Ethernet/IP remote I/O module for system automation. Lastly, the electrical terminal block provides access to all signals of the unit, with color-coded terminals: yellow for inputs, blue for outputs, and grey for power supply and PE signals.

- AE-PLC-APS. Unit:

- Table with four wheels with brakes mounted with aluminum profiles.

- Ten pieces made of aluminum and plastic:

- Five pieces with hole.

- Five pieces without hole.

- Unit wired and programmed for the correct operation of the system.

- Light stack to indicate the state of the workstation:

- Green, yellow and red led lights.

- 360º visualization.

- Non-colored lens to avoid wrong interpretation with the lights turned off.

- Electrical terminal block to connect the individually identified inputs, outputs and power signals of the unit.

- Control panel:

- Differential magneto-thermal switch.

- Emergency pushbutton.

- Start/Stop switch.

- Light indicator to show the state of the workstation.

- Reset push-button.

- Manual/automatic switch.

- Next step push-button.

- Two Ethernet/IP RJ45 connectors.

- Power switch.

- Power supply of 24 VDC.

- Air treatment unit:

- Filter-regulator and water trap.

- Manometer with double scale indicator.

- Shut-off valve.

- Purge valve.

- Piece feeder module:

- Vertical storage for pieces.

- Double acting cylinder:

- Two adjustable air flow valves with bypass.

- Pneumatic monostable 5/2 solenoid valve.

- Capacitive sensor.

- Two reed switches.

- Piece verifier module:

- Double acting cylinder:

- Two adjustable air flow valves with bypass.

- Pneumatic monostable 5/2 solenoid valve.

- Capacitive sensor.

- Three reed effect.

- Piece displacement module:

- Double acting cylinder:

- Two adjustable air flow valves with bypass and piloted check valve.

- Two Pneumatic monostable 3/2 solenoid valves.

- Piece classification module:

- Double acting cylinder:

- Normally retracted rod.

- Adjustable air flow valve with bypass.

- Pneumatic monostable 3/2 solenoid valve: Inductive effect sensor.

- Fault generation module:

- Attached to the frame of the unit.

- Generates faults in the operation of different elements of the unit using switches.

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with 7 manuals: Required services, Assembly and Installation, Control software, Starting-up, Safety, Maintenance and Practices manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Introduction to flexible manufacturing system; identification of unit components.

- Configuration of a pneumatic application

- Manual pieces feeding process with verifying function.

- Automatic pieces feeding process with verifying function.

- Optimizing the automatic pieces feeding process with verifying function.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review