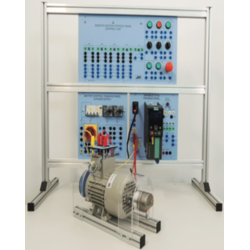

Bottling Workstation (AE-PLC-MEMB)

PL-545410

The Bottling Workstation, “AE-PLC-MEMB”, developed by EDIBON, is an automated rotary table system designed for the complete bottling process. It integrates a vessel feeding mechanism, a controlled water filling system, a cap feeding mechanism, a container closing system, and an extraction module to transfer the filled and sealed containers to a storage rack.

The “AE-PLC-MEMB” is designed as a modular system, allowing users to easily understand and follow the sequence of operations.

Main Components:

- PLC Unit: Includes the CPU and all required I/O modules necessary for the proper operation of the workstation.

- Control Panel: Equipped with start/stop buttons, emergency stop button, reset button, and indicator lights for monitoring the system status during operation.

- Pneumatic Circuit: Contains all necessary solenoid valves, pressure regulation components, filters, and pneumatic actuators required to execute the different stages of the process.

- Workstation: Made up of industrial-grade components typically used in rotary table systems, such as reed switches, presence sensors, capacitive and inductive sensors, DC motor, and a four-position rotary table.

Functional Sections:

- Air Treatment System: Features a filter-regulator block with water trap and shut-off valve to control air supply. A dual-scale manometer is included to monitor system pressure.

- Vessel Feed Section: Includes a vertical magazine for storing empty containers without caps. Two double-acting pneumatic cylinders allow the release of one container at a time, with independent flow regulators to adjust the speed of each actuator.

- Container Displacement Section: A rotary table with four dedicated positions rotates containers through each processing stage. Rotation is driven by a DC motor.

- Filling Section: Composed of two tanks – one as a water reservoir and the other supplying water to the containers. A submersible DC-powered pump, a siphon mechanism, and solenoid valves control the water flow. A capacitive sensor ensures containers are present before initiating the filling process, preventing overflow or accidental activation.

- Lid Feeding and Container Closing Section: A vertical magazine holds the lids. A double-acting cylinder pushes the lids one by one into position. Using vertical and horizontal displacement actuators and a vacuum ejector with suction cup, the lid is placed and pressed onto the container for sealing.

- Container Extraction Section: Equipped with pneumatic actuators and grippers to pick up the sealed containers and transfer them to a designated rack for storage.

- Signal Tower: Displays system status using green, yellow, and red LED indicators.

- Solenoid Valve Block: A pneumatic manifold with nine solenoid valves: eight 5/2 monostable valves and one 3/2 monostable valve.

- Electrical Terminal Block: Provides access to all input/output signals for manual testing. Color-coded terminals assist in identifying signal types, and each terminal is clearly labeled with its corresponding signal name.

- AE-PLC-MEMB. Station:

The “AE-PLC-MEMB” pneumatic station includes the following elements:

Unit operation signal lights.

Pneumatic circuit:

- Pneumatic actuators:

- Two single acting pneumatic cylinders ∅20 x 50 mm stroke.

- Pneumatic cylinder guide 10 mm stroke.

- Pneumatic actuator without piston 150 mm stroke.

- Two pneumatic guide cylinders 40 mm stroke with sliding bearing.

- Venturi effect vacuum ejector 1/8 outlet with 8 mm cup suction cup.

- Double acting pneumatic clamps.

- Adjustable double acting pneumatic rotary actuator with rotation capacity of 190°.

- Eight monostable five-way solenoid valves with 1/8 connection, 24 VDC.

- Monostable three-way solenoid valve with 1/8 connection 24 VDC, for the vacuum ejector.

- 17 flow regulators.

- Nine coils for pneumatic valves 24 VDC.

- Two base plates for connection of five and four pneumatic solenoid valves 1/8.

- 6 mm diameter conduction hose.

- Connecting fittings for 6 mm hose.

- Air treatment unit:

- Filter-regulator with water collector.

- Pressure gauge with double scale indicator.

- Shut-off valve.

Rotary table:

- 350 mm diameter table.

- Four supports for fixing the position of the container on the table.

- DC stepper motor.

- Dryve D8, stepper motor control system/direction.

- Zero point sensor for the motor.

- Connection cables.

Container feeder:

- Metraquilate tube ∅40 x ∅34.

- Cylinder adapter for opening or closing the tube section. Attached to the piston rod of the 50 mm stroke pneumatic cylinder.

- Guide for adapter. Fixed to the aluminum profile. Prevents the rotation of the previous adapter.

- Pusher to prevent two containers from falling at the same time. Fixed to the pneumatic cylinder with 10 mm stroke guide.

- Metraquilate tube fixing brackets.

- Adapter for container detection sensor, fixed to the profile.

- 20 Containers ∅32 x 50 mm high.

Cap feeder:

- Slotted metraquilate tube for cap storage.

- Cap pusher fixed to the pneumatic cylinder with 50 mm stroke.

- Guide rail for the displacement of the pusher.

- Lids of ∅33 and 8 mm thick.Extraction rail for containers.

Filling system:

- Two tanks to store water.

- Two solenoid valves. One to operate the pump, and the other to allow the transfer of water from one tank to another.

- 12 VDC submersible pump with a flow rate of 8 l/min.

- Adapter for pump attachment.

- Siphon collector.

- Aluminum siphon.

Sensors:

- Four capacitive sensors:

- Detection of container in feeder.

- Detection of container to start filling.

- Detection of cap in feeder.

- Level gauge in tank.

- Two magnetic reed sensors.

- 13 limit switch sensors.

PLC Programming Software:

- Programming software developed according to the standard IEC 61131 – 3.

- Compatible with Windows operating systems.

- Five programming languages: Ladder Diagram (LD). Structured Text (ST). Instructions List (IL). Sequential Function Chart (SFC). Function Block Diagram (FBD).

- Remote programming, service, and diagnostics.

- Minimum program size.

- Powerful debugging and monitoring tools.

- Supports user created functions and function blocks.

- Saves project files inside the PLC.

- Examples and Quick Start Tutorial included.

HMI Touch Screen Programming Software

- Tools for Screen Creation: This Software is a tool designed for programming touch type screens. Thanks to this tool, suitable screens and images can be created and designed. It allows to transfer the program to the screen, load projects done from the terminal and print screens created.

- Plenty of functions. Screens Creation: This Software has plenty of programming tools. Devices for visualizing texts, diagrams or data; drawing a button, graph, pilots. This Software allows to create functional screens adaptable to each application.

- Drawing Functions: It can be done different programming elements through suitable icons and bitmaps.

- Easy Operativity (Click and slip): A library of elements allows to program through the mouse, simply slipping an element and locating it in its place. (Click and Slip).

- Easy creation of user libraries: User libraries can be registered and stored with suitable elements to be used in next projects.

- Printing. The different screens of the project can be printed: It is possible to visualize a preliminary view. It is also possible to select the screens or configurations to be printed.

- Easy use. Bitmaps Editor: There is a tool that allows to create, read and modify bitmaps in order to use them as screen programming elements. Suitable buttons created from images can be easily made.

Control panel:

- Mushroom head emergency stop push button switch.

- Start and stop pushbuttons.

- Switch for manual or automatic operation.

- Light indicator.

- Led stack light.

- Terminal block to connect the individually identified inputs and outputs of the unit.

- Cables and Accessories, for normal operation.

- Manuals: This unit is supplied with manuals: Required services, Assembly and Installation, Control software, Starting-up, Safety, Maintenance and Practices manuals.

EXERCISES AND PRACTICAL POSSIBILITIES TO BE DONE WITH THE MAIN ITEMS

- Introduction to Flexible Manufacturing System (FMS).

- Introduction to pneumatics and electro-pneumatics.

- Pneumatic application configuration.

- Introduction to pneumatic control.

- Study of the detection sensors.

- Manual control of a rotary table.

- Automatic control of a rotary table.

- Example of industrial application.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review