ATLAS SERIES CNC ROUTER (Atlas)

PL-455621

The Atlas series machine is an all steel constructed machine providing a rigid foundation required for ultra-smooth routing results. The Atlas machine includes a 4HP HSD collet spindle includes a dust hood that has concentrated air flow at the cutter which provides optimal dust collection performance. The multi-zone vacuum t-slot table is constructed from very hard Phenolic which is very stable material, and holds tight tolerances for precision cutting, connected to a 10HP Rotary vane vacuum pump (twin pack optional) which has very quiet operation (82db). The Atlas series is powered by brushless stepper motors (servo optional), and is controlled via easy to learn and use hand held controller (PC based controller optional).

- 4′ x 4′, 4′ x 8′ and 5′ x 10′ stock sizes (Special sizes available upon request.)

- 4 HP HSD high-frequency collet spindle

- Maintenance free brushless stepper drive motors

- Multi-zone vacuum t-slot table

- Easy to use hand-held controller (optional PC based system available)

- Open architecture works with all industry standard CAD/CAM software

SPINDLE

The Atlas machine comes standard with a 4 HP HSD high frequency collet spindle. These precision spindles require no maintenance, use industry standard ER collets, come fully programmable speeds from 6000 to 18000 RPM, and come complete with a vacuum hood and wrenches.

GANTRY

The gantry is constructed of tubular steel with reinforcing ribs, welded throughout the length of the column, which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

VACUUM TABLE

The vacuum plenum table surface is single-zoned, which is controlled via main gate valve. The table can be zoned by easily moving gasket around to customize specific sections. Gasketing can also be routed to accommodate various material sizes and styles

BASE

The base frame is fabricated from heavy-duty tubular steel that is welded, stress relieved and precision machined, so that the foundation remains true and steady over the operational life of the machine

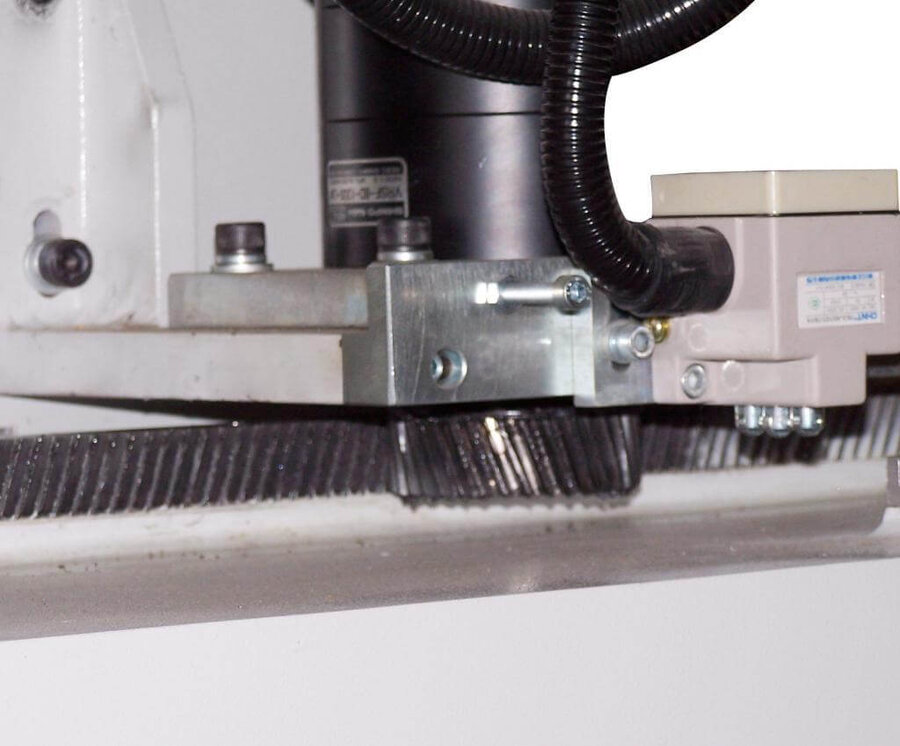

DRIVE TRAIN ASSEMBLY

The Techno Atlas CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system. This assures smooth motion and long term reliability. The precision gearbox is directly coupled to the stepper motor and pinion. This eliminates belt stretch inaccuracies, assuring high-speed machining while the system positions the spindle accurately

TOOL CALIBRATION

Automatic tool calibration pad allows for easy and accurate “Z” zero position.

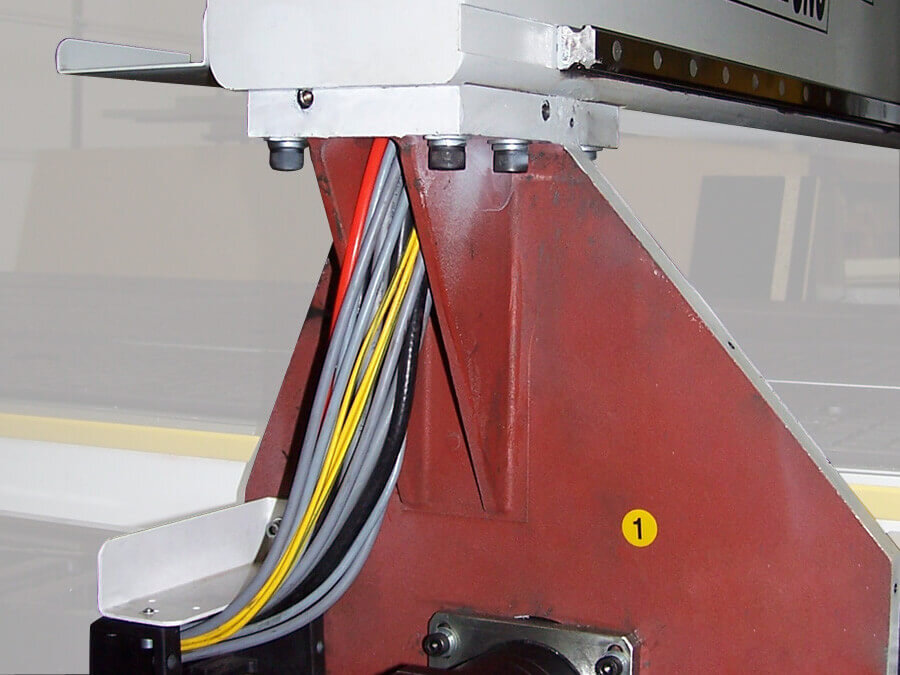

GANTRY UPRIGHTS

The gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, belts, and wiring harnesses.

ELECTRONICS

All the electrical components are housed and wired in a doubledoored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet. In addition, the cabinet serves as a work bench for the tools required

OPTIONAL

RAISED GANTRY

11-1/2″ or 16″ raised gantry option available

DUAL SPINDLE

Techno can equip an Atlas model machine with up to 3 spindles, so 3 identical parts can be cut simultaneously, thus increasing a company’s part production. Mounted on a common single t-slot plate provides users the ability to quickly, and easily, change spindle center spacing.

CONTROLLER OPTIONS (see product pictures)

- Hand-Held Controller

- SSA 5000 Controller

- Win CNC Controller

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review