HD II TABLETOP (HD-II)

PL-722152

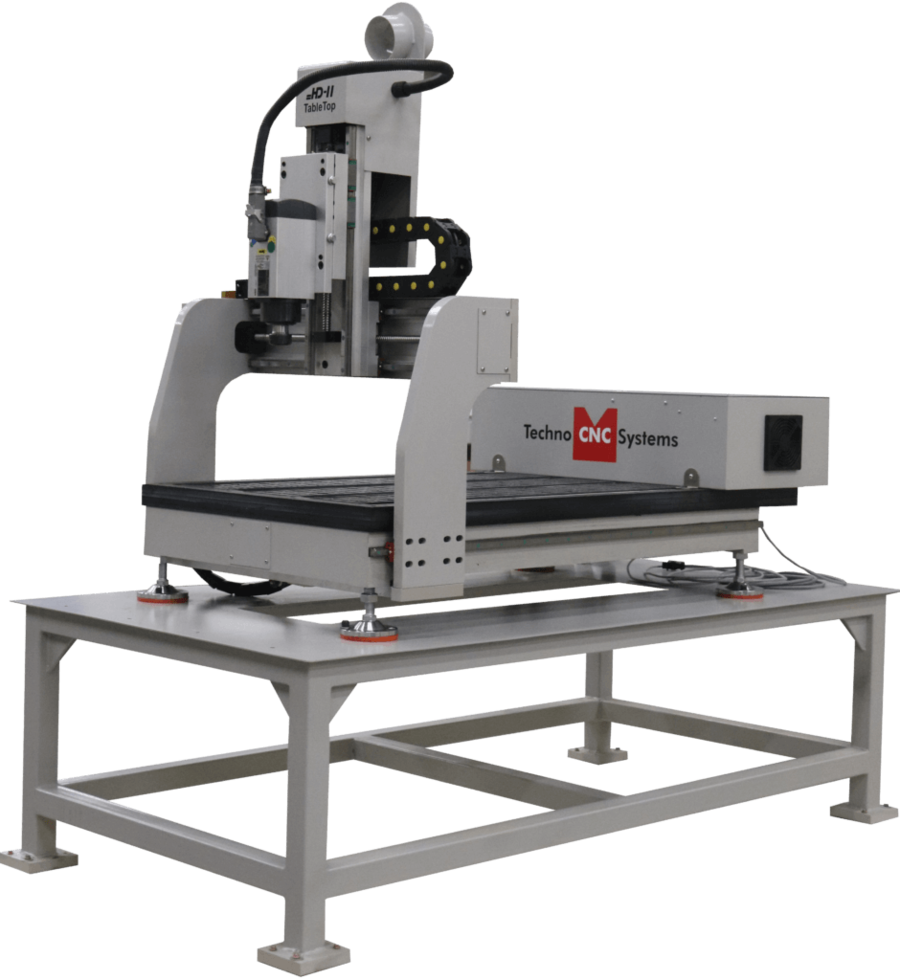

The HD-II Table top CNC router. This machine includes a 2HP HSD high frequency collet spindle, vacuum t-slot table which allows for mechanical clamping or vacuum hold down (pump optional). The gantry height is 7-1/2" which provide maximum flexibility to route sheet goods and larger taller parts if so desired. The machine drive motors are Nema 34 powerful high speed stepper motors, thus providing the power to route any wood, plastic, foam, or non-ferrous metals.

The controller is a stand-alone hand held controller. The buttons on the controller are all pre-programmed to perform certain machine instructions, thus making machine operations easy for instructors and student to learn and use the machine. No other machine on the market includes all of these features and capabilities. In addition the machines base has casters with locking wheels thus making this machine very portable.

- Steel base with casters

- Full safety enclosure

- Cam Clamp

- Clamp bar

- Vise

- Vacuum pump

- 1 1/2 HP dust collector

- Toggle clamp set (4 pc)

- Coolant system

- 4th Axis rotary table with tailstock

FEATURES:

- 20” x 30” Process Area

- Precision ball screws on all three axes

- 2 HP HSD high frequency collet spindle

- Brushless micro stepper motors and controls

- Vacuum T-slot table for easy part fixturing

- Easy-to-use hand held controller

- Automatic tool calibration pad

- Precision linear rails and bearings

SPINDLE

The HD II Tabletop CNC router comes equipped with a 2 HP HSD high frequency collet spindle.

VACUUM TABLE

Techno vacuum t-slot table comes standard on our HD-II machine. This unique design features multi-port zone sections which allows users to move gasketing around to create concentrated vacuum zones, where desired. The heavy duty aluminum t-slots allow for mechanical fixturing, if vacuum is not required.

TECHNICAL SUPPORT

Technical support, application engineering assistance, and remote diagnostics is FREE for the life of the machine via telephone, email, and remote logins

CONTROLLER OPTIONS

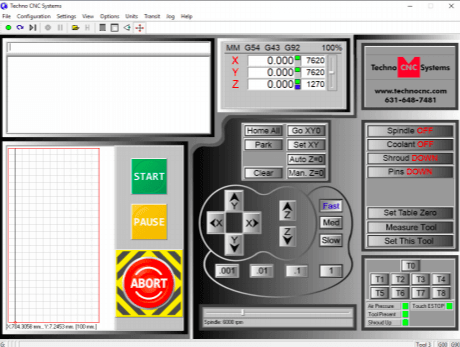

Hand-Held Controller

The hand-held controller is the heart of the operational system. This hand-held controller redefines the phrase “easy-to-use”. Customers can be up and running the same day power is connected to the machine. The setup introduction manual provides information that will have users cutting parts in minutes

SSA 5000 Controller

Our New Techno PC based industrial SSA 5000 controller is a Windows 10 based operating system. System connection is Ethernet for high speed communication resulting in high speed uninterrupted processing.

Win CNC Controller

The WinCNC interface is a controller system with step jog for fine incremental control, start, stop and pause buttons, single button for safety clearance position, absolute and relative coordinates control, and more.

OPTIONAL

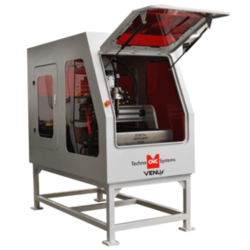

Safety Enclosure:

Techno’s heavy duty steel base includes hand jack center cross strut for easy maneuverability. Techno’s safety enclosure feature ergonomic front main door with vertical swing, two side doors, (8) enclosure viewing windows, and 3.0” top dust collection port. Techno’s HD-II Table top router with stand and enclosure is designed to roll through a standard 36” door opening making this model machine easy and convenient to move around the facility.

Coolant System:

The Micro-Drop Coolant System is ideal for use with the Techno machines. The unit’s micro dispenser delivers a very small amount of high-performance vegetable-based lubricant to the cutting tool by atomizing the lubricant in a high-velocity air stream. The result is higher material removal rates, improved finish, tighter tolerances and increased productivity.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review