Titan Series CNC Router (Titan)

PL-478952

The Titan Series machine is all steel construction, providing the rigid foundation required for ultra-smooth routing results. The Titan machine includes a 12HP HSD automatic tool changer with 8-position tool rack, and a pneumatically operated dust collection hood that concentrates air flow at the cutter, which provides optimal dust collection performance. The multi-zone vacuum t-slot table is constructed from very hard Phenolic, which is very stable material, and holds tight tolerances for precision cutting. The Titan series is connected to a 10HP Rotary vane vacuum pump, which has very quiet operation (82db). For easy sheet alignment, (3) material pop-up pins are included and precisely placed to handle and align various size materials. The Titan series is powered by brushless drive motors, and is controlled via easy to use and learn hand held controller (PC based controller optional).

FEATURES:

12 HP HSD high frequency automatic tool changer spindle

Maintenance free brushless motors and drives

Multi-zone vacuum t-slot table

Pneumatic material pop-up pins

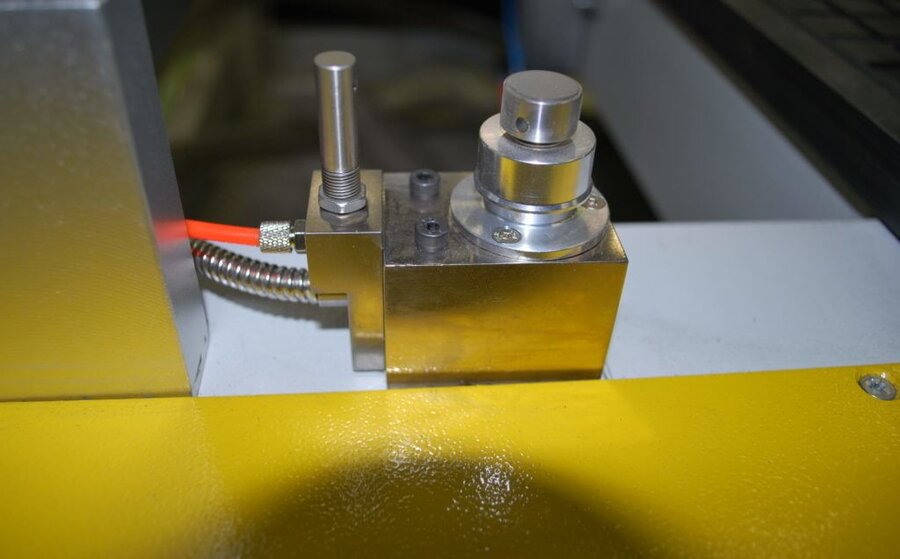

Automatic tool length calibration via closed loop touch pad

Automatic z-zero via secondary touch pad

Easy-to-use hand held controller (optional PC based system available)

Open architecture works with all industry standard CAD/CAM software

SPINDLE

The Titan Series machine comes standard with a 12 HP HSD high frequency automatic tool changer spindle. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, is fully programmable with speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood

GANTRY

The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm

beam assembly. This quality engineering and workmanship result in smooth precision cutting.

TOOL HOLDER CLAMP

The Techno Titan CNC Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier than using the common procedure of tightening the collet nut with two wrenches

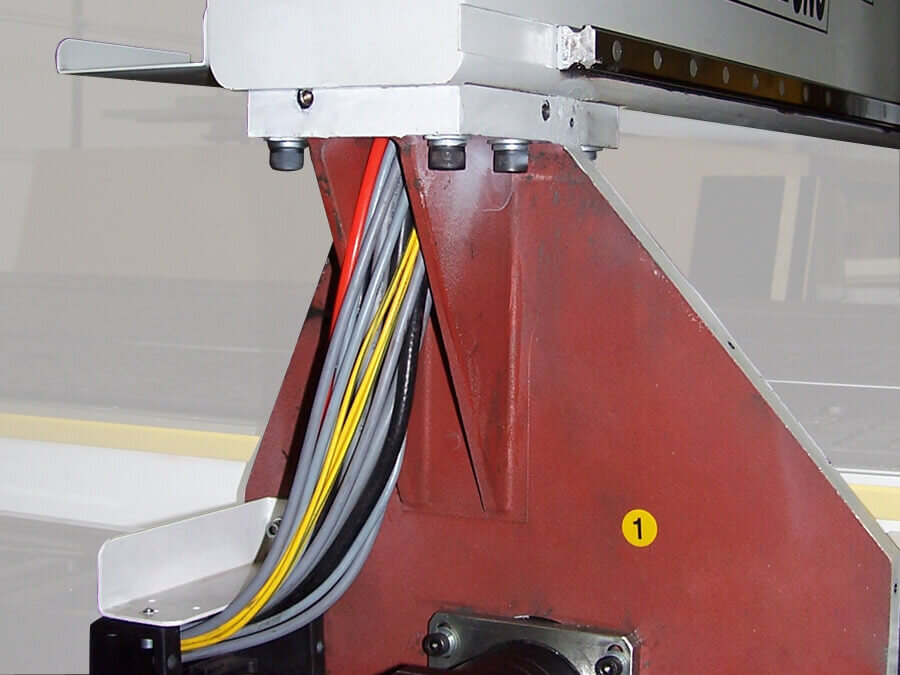

GANTRY UPRIGHTS

The gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, belts, and wiring harnesses.

DRIVE TRAIN ASSEMBLY

The Techno Titan Series CNC Router uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, this assures smooth motion and long term reliability. The precision gearbox is directly coupled to the drive motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system.

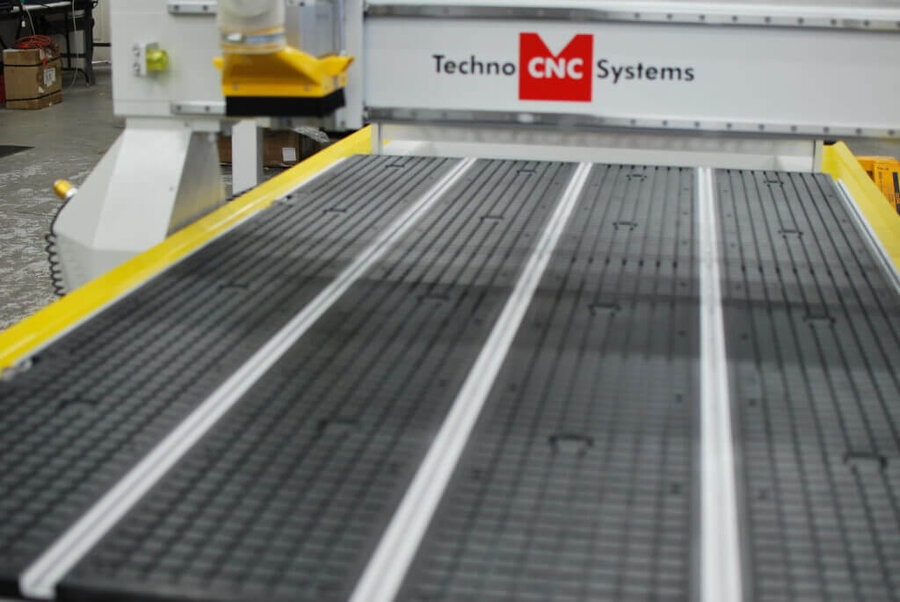

VACUUM TABLE

The Titan machine includes a vacuum t-slot table that can be easily customized to fit your particular part geometry. The grid allows the gasketing to be routed around the table sections. In addition it included rubber plugs for zoning off specific areas. Vacuum flow is controlled via a main gate valve which lowers operating costs and save vane life.

ELECTRONICS

All the electrical components are housed and wired in a doubled-doored Nema electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet. In addition, the cabinet serves as a work bench for the tools

TOOLING

The Titan Series machine includes an 8-position tool rack in the rear of the machine. The position of this rack allows for easy loading and unloading of material from either side of the machine.

DRIVE MOTORS

The Titan Series CNC Router utilizes brushless drive motors and drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

TOOL CALIBRATION

Tool Calibration is used for recording tool length offsets. This is an automatic process for easy storage of tool length offsets

Z-ZERO TOUCH PAD

Automatic tool calibration pad allows for easy and accurate “Z” zero position for single and multiple tool changes through the program.

CONTROLLER OPTIONS

Hand-Held Controller

The hand-held controller is the heart of the operational system. This hand-held controller redefines the phrase “easy-to-use”. Customers can be up and running the same day power is connected to the machine. The setup introduction manual provides information that will have users cutting parts in minutes

SSA 5000 Controller

Our New Techno PC based industrial SSA 5000 controller is a Windows 10 based operating system. System connection is Ethernet for high speed communication resulting in high speed uninterrupted processing.

Win CNC Controller

The WinCNC interface is a controller system with step jog for fine incremental control, start, stop and pause buttons, single button for safety clearance position, absolute and relative coordinates control, and more.

What is this?

These percentage scores are an average of 0 user reviews. To get more into detail, see each review and comments as per below

If you have used this product, support the community by submitting your review