Process Control Training Equipment

Sort by

Learn more about Process Control Training Equipment

In this section you will learn more about Process Control Training Equipment and different instructional tools, and how they are used to teach learners about technology in different processing industries, in an engaging hands on manner.

What is Process Control Training Equipment?

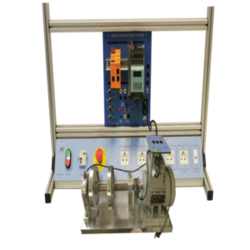

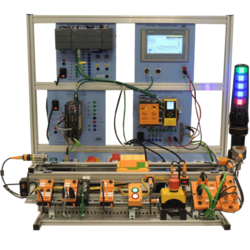

Process control training equipment consists of educational tools and systems designed to teach the principles and practices of process control in industrial settings. These training systems are used to simulate real-world process environments where variables such as temperature, pressure, flow, and level are monitored and adjusted to maintain desired outcomes.

Process control is critical in industries such as chemical, pharmaceutical, oil and gas, and manufacturing, where precise control over processes ensures product quality, efficiency, and safety. The training equipment helps learners understand how to design, implement, and troubleshoot process control systems, making them essential for both academic and industrial training.

What Type of Process Control Training Equipment Exists?

Basic Process Control Trainers:

- Temperature Control Units: Simulate systems where temperature needs to be monitored and maintained within specific limits, such as in heating systems or reactors.

- Pressure Control Trainers: Teach how to control and regulate pressure in systems, such as in boilers or pipelines, ensuring safe and efficient operation.

- Flow Control Trainers: Focus on controlling the flow of liquids or gases through pipelines, important in processes like water treatment or chemical production.

Advanced Process Control Systems:

- Distributed Control Systems (DCS) Trainers: Provide hands-on experience with complex, networked control systems used in large-scale industrial processes. These trainers simulate environments where multiple process variables are controlled simultaneously.

- Supervisory Control and Data Acquisition (SCADA) Systems: Used for teaching remote monitoring and control of industrial processes, SCADA systems are crucial in industries such as power generation and water management.

Programmable Logic Controller (PLC) Trainers:

- PLC-Based Process Control Systems: These trainers integrate PLCs with various process control elements, teaching how to automate and control processes using programmable logic controllers.

Batch Process Control Trainers:

- Batch Process Simulators: Used to train on the management and control of batch production processes, where discrete quantities of materials are processed in sequence, such as in food production or pharmaceuticals.

Instrumentation and Measurement Trainers:

- Sensor and Transducer Trainers: Teach the use and calibration of sensors that measure process variables like temperature, pressure, flow, and level, which are critical for feedback in control systems.

- Signal Conditioning and Data Acquisition Systems: Train on how to process and analyze data from various sensors, ensuring accurate and reliable control.

Virtual and Augmented Reality Process Control Training:

- VR/AR Simulation Systems: Provide immersive environments where learners can interact with process control systems and equipment in a virtual space, enhancing understanding without the need for physical equipment.

Why Use Process Control Training Equipment?

Process control training equipment is essential for several key reasons:

-

Practical Skill Development: These systems allow learners to gain hands-on experience in controlling and optimizing industrial processes, which is critical for ensuring efficiency, safety, and product quality in real-world operations.

-

Enhanced Understanding of Complex Systems: Process control involves managing multiple variables simultaneously. Training equipment helps learners grasp the complexities of these systems, including how changes in one variable can affect others.

-

Preparation for Industry Standards: These tools prepare students and professionals to meet industry standards, ensuring they are familiar with the technologies and methodologies used in modern process control.

-

Safe Learning Environment: Training on simulated equipment allows learners to experiment and make mistakes without the risks associated with real-world industrial environments, such as equipment damage or safety hazards.

-

Adaptation to Technological Advances: As process control technology evolves, training equipment helps learners stay current with the latest advancements, such as digital control systems, automation, and smart sensors.

-

Improving Troubleshooting Skills: By working with training equipment, learners develop critical troubleshooting skills, enabling them to diagnose and correct issues in process control systems quickly and effectively.

Best Practices for Using Process Control Training Equipment

To maximize the benefits of process control training equipment, it's important to follow these best practices:

-

Structured Curriculum Integration: Ensure that the training equipment is integrated into a structured curriculum that covers both theoretical concepts and practical applications. This alignment helps reinforce learning and ensures that students gain a comprehensive understanding.

-

Safety Training: Emphasize safety protocols when using process control training equipment. Even in a simulated environment, understanding the importance of safety is critical when transitioning to real-world applications.

-

Regular Equipment Maintenance: Keep the training equipment in good working order through regular maintenance and calibration. This ensures accurate simulation of real-world conditions and reliable operation during training sessions.

-

Hands-On Practice: Encourage extensive hands-on practice to build confidence and competence in operating and troubleshooting process control systems.

-

Scenario-Based Training: Use scenario-based training exercises to simulate common industrial challenges, such as process disturbances or equipment failures. This approach helps learners develop problem-solving skills and adaptability.

-

Documentation and Analysis: Encourage trainees to document their experiments and results, analyzing their performance and the outcomes of different control strategies. This reflective practice deepens understanding and promotes continuous improvement.

-

Continuous Assessment: Implement regular assessments to evaluate learners’ understanding and skills. Use these assessments to provide feedback and guide further learning.

-

Industry Collaboration: Engage with industry partners to ensure the training equipment and curriculum reflect current industry practices and technologies, making the training relevant and valuable for future employment.

By adhering to these best practices, institutions and companies can effectively use process control training equipment to develop a skilled workforce capable of managing and optimizing complex industrial processes.